- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- storage automation

Results for

Storage automation - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Smooth final assembly The many different processes included in final assembly require precisely timed provision of parts and ergonomic support for manual work. Your advantages using Lödige solutions during final assembly Ergonomic work platforms Connection to high-bay warehousing Efficient preparation of different assemblies Linked materials handling systems Quick access to assemblies in intermediate storage Automation

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Fully automated storage In the automotive industry, storage in high-bay warehousing and precise, sequential provision are a vital part of the production process. Your advantages using Lödige solutions for efficient storage and order picking Custom-made racking systems Optimum use of space Storage for every sort of component Connection to internal materials handling systems Storage, materials handling and control technology — all from one source Quick and safe storage

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Storage systems from Lödige provide a total integrated solution for parts and tools to be stored in an efficient and save-spacing saving way. Lödige storage systems can be fully automated to store and transport anything from small parts to very large and heavy aircraft parts and tools. We develop high-throughput storage systems in line with customer requirements to support your dispatch reliability and speed.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Precision handling for heavy loads From end-of-line, through rack handling, to automated storage: Lödige has complete control of all the materials handling processes required in the press shop — including tool handling and systems for improved tool maintenance. Your advantages using Lödige solutions in the press shop: Ergonomic tool maintenance Coil handling up to 40 t Safe provision of pressed components Lifting and tilting tables up to 40 t Connection to pressed component storage Linked materials handling systems

Request for a quote

TRAPO GMBH

Germany

Between the shelves of the high-bay storage are corridors in which the TWS function. They are controlled through the lane with the assistance of the TWL in order to load and retrieve products or load carriers at different levels. A combination which, through automation, utilizes maximum storage capacity, sustainably saves costs, avoids fault sources and enables an efficient working method.

Request for a quote

SAMSYS GMBH

Germany

The ProFeeder Compact from EasyRobotics is a robust robotic cell with compact dimensions that can be easily moved in your production. The ProFeeder Compact is placed separately in front of the machine to be operated. Then an ER Work or an ER Pedestal is positioned in front of the machine. The robot is located on the ER Work / ER Pedestal. The robot now takes workpieces from the ProFeeder Compact and loads and unloads the machine. It then loads the workpieces back into the ProFeeder Compact. This results in advantages for you, such as more space in your production, quick adaptability for different workpieces and a mobile robot cell. Thanks to the simple design of the drawers of the ProFeeder Compact, workpieces of various sizes and lengths can be processed without major changeover work.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP welded tanks are erected using the LIPP Welding Technology, a unique method of construction enabled by a custom automated rig designed and manufactured by LIPP. This procedure can claim a number of advantages over other traditional welding methods. Firstly, the unique steel profile increases stability and so reduces material costs at the same time. Secondly, the automated endless tape process continually welds layers below in a rotational cycle and reduces the number of on site workers. LIPP Welding Technology enables welding both black steel and stainless steel of different grades, allowing numerous applications. LIPP aims to increase construction efficiency through the implementation of unique techniques and technology, ultimately benefiting customers via a cost effective system. The key facets for the construction of a LIPP storage system are automation, continuously variable tank dimensions, reduced space requirements for onsite construction and increased worker safety.

Request for a quote

EXCOR KORROSIONSSCHUTZ-TECHNOLOGIEN UND -PRODUKTE GMBH

Germany

EXCOR VALENO Trays and Containers are made of hard plastics based on polyethylene and polypropylene and manufactured using deep-drawing or injection moulding techniques. The durability of these containers makes them the ideal choice for multiple uses, or may with narrower walls be employed as single-use packaging. The work pieces or small loads to be transported fit snugly into the containers. No additional VCI diffusers are needed since the plastic is impregnated with VCI substances. These two combined properties markedly simplify every kind of automated transport and storage process. Provided the instructions for use are followed EXCOR VALENO Trays and Containers will offer corrosion protection for up to five years.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Manual feeding system , automated feeding system is also available up to your request Drum blender with paddles and gravity positioning flow system Fast and automated powder storage release system . HMI, PLC with SCADA system integrated for easy workflow Tunnel conveyor transfer system for quick and easy powder transfer Automatic weighing tower Electropneumatic Automatic weighing cells Vertical powder packaging machine Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Automated feeding system is also available up to your request Drum blender with paddles and gravity positioning flow system Fast and automated powder storage release system . HMI, PLC with SCADA system integrated for easy workflow Tunnel conveyor transfer system for quick and easy powder transfer Horizontal powder packaging machine Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Intelligent Storage Management With the ISM 400 you can flexibly store 7“, 13“ and 15“ reels, trays, tubes, printed circuit boards, well equipped feeder, solding pastes or screen printing frames manually and monitor their insertion and extraction. The different configuration possibilities of the ISM 400 satisfy the storage needs of the most varied types of components as well as operational and consumable resources of a modern SMT production. With the help of the optional humidity control module it is possible to constantly adjust and monitor the humidity level within the system.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Intelligent Storage Management The ISM 500, JUKIs intelligent dynamic storage solution, has been developed to satisfy the storage needs of the most varied types of components. With the possibility to configure up to 640 different positions, the operator can insert 7″, 13″ and 15″ reels, JEDEC trays, SMT and THT tubes, screen printing frames and foils, THT components etc.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Intelligent Storage Management The flexible storage solution of the ISM 1100 allows flexible storage, intelligent monitoring as well as fully automatic insertion and extraction of up to 1,100 7“ reels on an effective area of just 1.6 m². During the fully automatic insertion and extraction of up to 27 reels there is no user intervention necessary.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Intelligent Storage Management The intelligent storage management system of the ISM 2000 has been specifically designed to obtain optimum performance regarding storage capacity and total size. The automated system allows fast insertion and extraction of reels and trays stored in standard cases, while the patented multiple outlet enables the simultaneous extraction and insertion of up to 27 reels at a time. Optionally, a module for automatic wireless extraction is available as well as a humidity control unit to control humidity of all of the components inside the ISM systems.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Intelligent Storage Management Designed as an extension module for the ISM UltraFlex 3600, JUKI’s ISM UltraFlex 3900 offers a thought out solution to efficiently use space in the warehouse by simply and quickly doubling storage capacities. JUKI’s ISM UltraFlex 3900 is a real space wonder allowing storage of up to 7,500 (7“ and 15“) reels in combination with JUKI’s ISM UltraFlex 3600. Operation and handling is exclusively done via the ISM UltraFlex 3600. Needless to say that all reels are stored fully automatic, very flexible and monitored intelligently.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Intelligent Storage Management An intelligent and efficient storage management is turning into the key success factor regarding SMT manufacturing. Hereby ensuring an ideal output while simultaneously securing the increasing flexibility of the product program. Our ISM storage management system provides you with this intelligent and flexible storage solution and helps you refocus on your value adding activities. Using the ISM UltraFlex 3600 you will be able to flexibly store up to 3,644 reels, monitor them intelligently as well as oversee the fully automatic import and export of the components.

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The COMPENSER® of the CE-series is a nonreversible maintenancefree shock reducing element / shock absorber which can be used for emergency use, for example as a fall protection. If necessary, several deformation tubes (so-called crash element) can be installed in parallel as end stops. Design & Function: The crash element is attached to the support structure using the flange 3. In the event of an impact, the stamp (acting as a mandrel) 1 enters the deformation tube 2 and expands it. Applications: Automated storage and retrieval system | Conveyor system | Storage technology | Automation | Heavy duty | Heavy equipment | Engineering | Crashtest | Flight simulator | Special construction | Special machines | Actuator | Test device | Small parts warehouse | High-bay warehouse | STC | HRL | Storage and retrieval systems (AS/RS) equipment | non reversible | Leakage-free | Shuttle

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

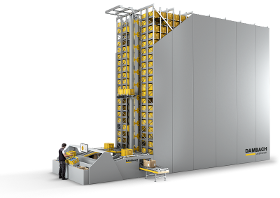

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

Automated small parts storage for a wide range of applications – whether as picking-, buffer- or distribution storage. A variety of small parts carriers and small containers can be stored efficiently with the LOGI-KIT MINI. The system is thereby as flexible as your requirements. Load weights can vary between a few grams up to 300 kg. With storage heights from 3 to 27 m, it can be integrated easily into many existing buildings. High goods throughput means that the system is perfectly suitable as a "micro-fulfillment" system in the tightest space. Cartons, Euro containers and trays are automatically transported to the picking station. The "goods-to-person" principle leads to the elimination of unproductive order picking way times and time needed for order fulfillment is reduced.

Request for a quote

KARDEX DEUTSCHLAND GMBH

Germany

Kardex Remstar introduces a new control generation to complement all Kardex Remstar automated storage and retrieval systems. This machine based control center brings major improvements in ergonomics and usability of Kardex Remstar automated storage and retrieval systems. It provides a simple, intuitive touchscreen user interface and a basic space management and reporting environment for the Shuttle XP and Megamat RS automated storage systems, with a new state-of-the-art design optimized for both touch and keyboard usage. For customers not requiring a WMS system, the Logicontrol provides an alternative machine based control solution, which means: No additional hardware required, no PC workstation required No loss of data and investment if upgrading to a PC based soft ware solution at a later stage

KARDEX DEUTSCHLAND GMBH

Germany

The Kardex Remstar Lektriever is a software controlled automated media storage and retrieval system that can hold thousands of files, videos, CD’s , DVD, or a host of other media. Its capacity is the equivalent of at least 16 four-drawer filing cabinets. It can be operated in a stand alone mode or networked to your IT systems. It is as easy to operate as a printer, simply click on the requested file or media type and the Lektriever will search, select and retrieve the requested item.

Results for

Storage automation - Import exportNumber of results

21 ProductsCountries

Company type