- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel bars

Results for

Steel bars - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used for printer accessories.

Request for a quote

ROLLON GMBH

Germany

The ECO SYSTEM units are linear actuators made of a self-sustaining extruded aluminum frame and are driven by a polyurethane belt with AT metric profile steel inserts. Three different sizes available: 60mm, 80mm, 100mm Version available with recirculating ball bearing or roller rails Reduced weight ensured by the light frame and the aluminum sliders High sliding speed The ECO SYSTEM series actuators are offered with two motion systems: ECO SYSTEM – SP Featuring a maintenance free recirculating linear guide rail fitted inside the profile. ECO SYSTEM – CI Featuring four rollers with a Gothic arch outer profile sliding on hardened steel bars placed inside the profile. Main fields of application for Eco System linear units: Automation Packaging Industrial machinery

Request for a quote

KEBA FASTENINGS

Germany

PRODUCTION CAPABILITIES KEBA Fastenings’ processing capacity for Turned-Parts comprised of steel, brass, aluminum, and stainless steel bars ranges between Ø 1mm to Ø 60mm via CNC Auto Lathe, Index, and Sliding Automat machinery. The manufacturing technology and team capabilities allow for custom made parts according to customer-specific drawings. SURFACE TREATMENT • Browning • Anodised • KTL • Zinc - Lamella • Galvanized (blue, yellow, black) • Zinc - Iron • Zinc - Nickle Powder • Phosphating • Chrome • Copper

Request for a quote

C+R HYDRAULICS GMBH

Germany

• flat steel • wide flat steel • strip steel • round steel • square steel • t-steel • u-steel • angled steel isoceles • angled steel non-isoceles

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

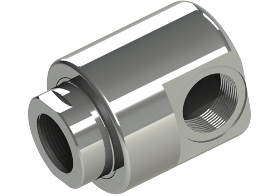

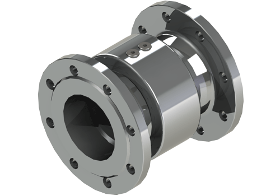

brass or stainless steel Vitonseal (FEP optional) builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed for simple applications for example hose reels PRESSURE MAXIMUM PRESSURE MAXIMUM 16 bar Stainless steel Brass PRESSURE MAXIMUM 16 bar Stainless steel Brass

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

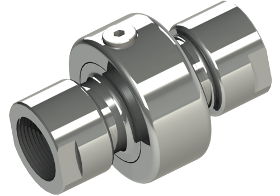

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding track similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM 40 bar Stainless steel 100 bar Steel 42CrMo4 SIZEDN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2")

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding track similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM 40 bar Stainless steel 100 bar Steel 42CrMo4 SIZEDN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4")

Request for a quote

SPANSET SECUTEX GMBH

Germany

Wipers for steel bars In the production of pipes and steel bars, socalled wipers are used for cleaning. The wipers have a round or rectangular outer profile and an inner profile that matches the shape of the object to be cleaned. Normally, several wipers are mounted in series, whereby the passthrough openings are smaller than the profile. The bar is pushed through the elastomer plates at high velocity, and the rubbery material strips the surface free from grease and cleaning fluid residues. It is the edge that counts! Just a like a car window wiper, it is the edge that counts. Normally, the wipers are stamped from sheet goods. During stamping, the elastomer becomes distorted; the inner edge is therefore not dimensionally stable and is at an angle. Only part of the edge wipes emulsions from the surfaces depends on the profiles. This edge is rapidly worn down; the cleaning action is then unsatisfactory. Streakfree cleaning

Request for a quote

C+R HYDRAULICS GMBH

Germany

Cold-rolled (2B/IIIc) and hot-rolled (1D/IIa) in the following versions: • foil-coated • ground • brushed • bright annealed (2R/IIId) in den formats: • small format 1.000 x 2.000 mm • medium format 1.250 x 2.500 mm • large format 1.500 x 3.000 mm • as well as custom dimensions upon request Stainless steel pipes and steel bars upon request

Request for a quote

SPANSET SECUTEX GMBH

Germany

Wipers for steel bars In the production of pipes and steel bars, socalled wipers are used for leaning. The wipers have a round or rectangular outer profile and an inner profile that matches the shape of the object to be cleaned. Normally, several wipers are mounted in series, whereby the passthrough openings are smaller than the profile. The bar is pushed through the elastomer plates at high velocity, and the rubbery material strips the surface free from grease and cleaning fluid residues. It is the edge that counts! Just a like a car window wiper, it is the edge that counts. Normally, the wipers are stamped from sheet goods. During stamping, the elastomer becomes distorted; the inner edge is therefore not dimensionally stable and is at an angle. Only part of the edge wipes emulsions from the surfaces depends on the profiles. This edge is rapidly worn down; the cleaning action is then unsatisfactory. Streakfree cleaning

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHMITTER HYDRAULIK GMBH

Germany

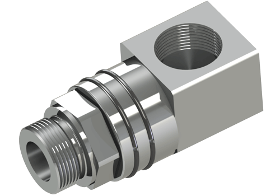

Tapered stems DIN 20034 material: steel, galvanized working pressure: 16 bar Category Compressed-air technology / Compressor fittings / Taper sleeves Product number supplier 333092500

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

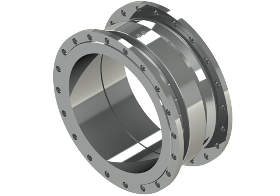

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM Steel 42CrMo4 16 bar DN 350 DN 400 DN 500 DN 600 DN 700 40 bar DN 125 (5") DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") Stainless steel 6 bar DN 350 DN 400 DN 500 DN 600 DN 700 16 bar DN 125 (5") DN 200 (8") DN 250 (10") DN 300 (12") SIZEDN 125 (5") DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") DN 350 DN 400 DN 500 DN 600 DN 700

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM Steel 42CrMo4 315 bar DN 32 (1 1/4") DN 40 (1 1/2") 350 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") Stainless steel 100 bar DN 32 (1 1/4") DN 40 (1 1/2") 160 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") PRESSURE MAXIMUM Steel 42CrMo4 315 bar DN 32 (1 1/4") DN 40 (1 1/2") 350 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") Stainless steel 100 bar DN 32 (1 1/4") DN 40 (1 1/2") 160 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1")

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

STEEL GRADES The standrard stock of chromed bars consists of steel grades C45 or C45E or C45R and 20MnV6 in untreated delivery condition (+AR) and 42CrMo4 in quenched and temperd delivery condition (+QT). DELIVERY CONDITIONS The solid bars subjected to chroming process are available in different delivery conditions in orde to obtain specific properties. NORMALIZATION Heat treatment consisting heating process followed by gradual cooling in controlled atmosphere. Thanks to this process the steel structure becomes more "refined" and improve its impact properties (perlitic structure). INDUCTION HARDENING The surface of the steel bar is heated by electric induction followed by fast cooling. This process leads to a high surface hardness but also to fragility and low impact values (Martensite surface structure). QUENCHING AND TEMPERING Quenching process followed by tempering. This process leads to a good hardness and resistance and it reduces its fragility in comparsion to induction...

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM Steel 42CrMo4 100 bar DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") 250 bar DN 65 (2 1/2") DN 80 (3") DN 100 (4") DN 125 (5") 350 bar DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") Stainless steel 40 bar DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") 100 bar DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4") DN 125 (5") SIZEDN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4") DN 125 (5") DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12")

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

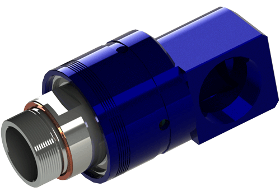

universal usecooling, heating, clamping, moving segment design sealingmaterial PTFECompound robust available in stainless steel PRESSURE MAXIMUM 10,0 bar air nontoxic gases water 250,0 bar hydraulic oil TEMPERATURE MAXIMUM 90 °C air hydraulic oil nontoxic gases vacuum water SPEED MAXIMUM 10 1/min 250 bar 80 1/min 50 bar

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal usecooling, heating, clamping, moving segment design sealingmaterial PTFECompound robust available in stainless steel PRESSURE MAXIMUM 10,0 bar air nontoxic gases water 250,0 bar hydraulic oil TEMPERATURE MAXIMUM 90 °C air hydraulic oil nontoxic gases vacuum water SPEED MAXIMUM 10 1/min 250 bar 250 1/min 60 bar

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal usecooling, heating, clamping, moving segment design sealingmaterial PTFECompound robust available in stainless steel PRESSURE MAXIMUM 10,0 bar air nontoxic gases water 250,0 bar hydraulic oil TEMPERATURE MAXIMUM 90 °C air hydraulic oil nontoxic gases vacuum water SPEED MAXIMUM 10 1/min 250 bar 250 1/min 60 bar

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal usecooling, heating, clamping, moving segment design sealingmaterial PTFECompound robust available in stainless steel PRESSURE MAXIMUM 10,0 bar air nontoxic gases water 250,0 bar hydraulic oil TEMPERATURE MAXIMUM 90 °C air hydraulic oil vacuum water SPEED MAXIMUM 10 1/min 250 bar 250 1/min 60 bar

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

ballbearings (can be relubricated) robust and less influence of dirty media self supportingno additional support necessary housing stainless steel rotor stainless steel PRESSURE MAXIMUM water 40 bar DN 50 (2") 50 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") TEMPERATURE MAXIMUM 130 °C water SPEED MAXIMUM 750 1/min DN 50 (2") 2500 1/min DN 32 (1 1/4") DN 40 (1 1/2") 3000 1/min DN 25 (1") 3500 1/min DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") SIZEDN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2")

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal use ballbearings (can be relubricated) robust and less influence of dirty media self supportingno additional support necessary housing aluminium, brass or stainless steel rotor stainless steel PRESSURE MAXIMUM vacuum 0 bar DN 6 (1/8") DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") air 10 bar DN 6 (1/8") DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") hydraulic oil 40 bar DN 50 (2") 50 bar DN 6 (1/8") DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") TEMPERATURE MAXIMUM 120 °C air hydraulic oil vacuum SPEED MAXIMUM 750 1/min DN 50 (2") 2500 1/min DN 32 (1 1/4") DN 40 (1 1/2") 3000 1/min DN 25 (1") 3500 1/min DN 6 (1/8") DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") SIZEDN 6 (1/8") DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2")

Request for a quote

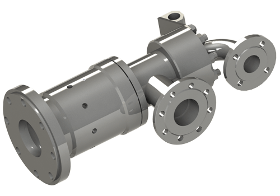

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

single inlet/outlet line or combined inlet/outlet line with stationary or rotating syphon pipe universal usecooling, heating, clamping series with ball bearings, graphite bushbearing or solid grease ballbearings bellows sealing available in stainless steel CDCartridgeDesign PRESSURE MAXIMUM 6,0 bar heat transfer oil 10,0 bar air nontoxic gases steam 17,0 bar water TEMPERATURE MAXIMUM 300 °C air heat transfer oil nontoxic gases steam vacuum water SPEED MAXIMUM 600 1/min DN 80 (3") DN 100 (4") DN 125 (5") SIZEDN 80 (3") DN 100 (4") DN 125 (5")

Request for a quoteResults for

Steel bars - Import exportNumber of results

49 ProductsCountries

Company type

Category

- Electric motors and parts (19)

- Vacuum cleaners, domestic (2)

- Bending - steels and metals (1)

- Concrete forms (1)

- Coupling, pneumatic (1)

- Fasteners, metal (1)

- Internal transport systems (1)

- Sawing machine tools (1)

- Steel & Metal Transformation (1)

- Testing equipment (1)

- Windscreen wipers (1)

- Wires and cables, steel (1)