- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel rolls

Results for

Stainless steel rolls - Import export

ACE STOSSDÄMPFER GMBH

Germany

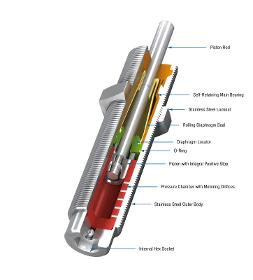

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology Energy capacity 136 Nm/cycle Stroke 25.4 mm Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in...

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

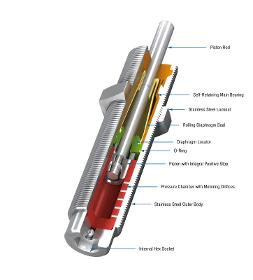

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology Energy capacity 41 Nm/cycle Stroke 12.5 mm Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in...

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

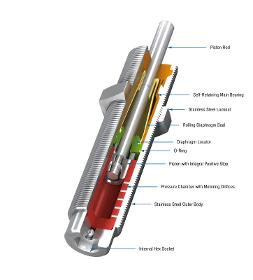

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology Energy capacity 20 Nm/cycle Stroke 12.5 mm Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in...

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Toilet roll holder with one concealed reserve roll in stainless steel (AISI 304) for surface mounting. Allstainless steel housing; all corners fully welded, visible surfaces satin finished and brushed. Designed for two standard toilet rolls, including one concealed reserve roll, which drops down automatically. Inspection slot to indicate fill level. Accessible for refilling through lockable front flap. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes fixing material. Dimensions 148 x 348 x 150 mm

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

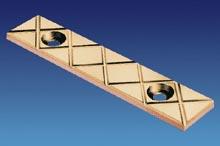

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: round Material: 1.4571 (X6CrNiMoTi17-12-2) Type of production: hot-rolled Surface: untreated Standard: EN 10095 eClass 9.1: 35010312 UNSPSC 11.2: 30102405 Dimensions: Diameter (mm): 25 - 400 Length (mm): 5,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: round Material: 1.4841 (X15CrNiSi25-21) Type of production: hot-rolled Surface: untreated Standard: EN 10095 eClass 9.1: 35010312 UNSPSC 11.2: 30102405 Dimensions: Diameter (mm): 60 - 75 Length (mm): 5,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: round Material: 1.4541 (X6CrNiTi18-10) Type of production: hot-rolled Surface: untreated Standard: EN 10088 eClass 9.1: 35010312 UNSPSC 11.2: 30102405 Dimensions: Diameter (mm): 30 - 120 Length (mm): 5,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: round Material: 1.4404 (X2CrNiMo17-12-2) Type of production: hot-rolled Surface: peeled Standard: EN 10088 eClass 9.1: 35010312 UNSPSC 11.2: 30102405 Dimensions: Diameter (mm): 160 - 250 Length (mm): 5,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: round Material: 1.4305 (X8CrNiS18-9) Type of production: hot-rolled Surface: untreated eClass 9.1: 35010312 UNSPSC 11.2: 30102405 Dimensions: Diameter (mm): 35 - 280 Length (mm): 5,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: round Material: 1.4301 (X5CrNi18-10) Type of production: hot-rolled Surface: untreated Standard: EN 10088 eClass 9.1: 35010312 UNSPSC 11.2: 30102405 Dimensions: Diameter (mm): 25 - 400 Length (mm): 5,000

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4571 (X6CrNiMoTi17-12-2) Manufacturing method: cold-rolled, 2B Surface finish: pickled Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 0.5 - 6 Length (mm): 2,000 - 4,000 Width (mm): 1,000 - 2,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4404 (X2CrNiMo17-12-2) Manufacturing method: cold-rolled, 2B Surface finish: pickled Norm: EN 10088 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 0.8 - 6 Length (mm): 2,000 - 4,000 Width (mm): 1,000 - 2,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: sheet Material: 1.4462 (X2CrNiMoN22-5-3) Method of manufacture: hot-rolled, 1D Surface finish: pickled Standard: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 4 - 10 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4828 (X15CrNiSi20-12) Manufacturing method: cold-rolled, 2B Surface finish: pickled Norm: EN 10095 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 1 - 3 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: sheet Material: 1.4301 (X5CrNi18-10) Type of manufacture: cold-rolled, 2G Surface finish: ground Standard: EN 10088-2 Grain: Grit 240 Ground sides: one-sided Dimensions: Thickness (mm): 0.6 - 8 Length (mm): 2,000 - 6,000 Width (mm): 1,000 - 2,000 Factory filming: Film 4228, Standard film, Laser protection film

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: sheet Material: 1.4016 (X6Cr17) Type of manufacture: cold-rolled, 2R Surface condition: bright annealed Standard: EN 10088 Dimensions: Thickness (mm): 0.5 - 3 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500 Factory filming: Standard film, no film, Laser protection film/without stamp, no paper

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4571 (X6CrNiMoTi17-12-2) Manufacturing method: hot-rolled, 1D Surface finish: pickled Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 3 - 12 Length (mm): 2,000 - 4,000 Width (mm): 1,000 - 2,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: sheet Material: 1.4301 (X5CrNi18-10) Type of manufacture: cold-rolled, 2G Surface finish: ground Standard: EN 10088-2 Grain: Grit 320 Ground sides: one-sided eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 0.8 - 2 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4462 (X2CrNiMoN22-5-3) Manufacturing method: cold-rolled, 2E Surface finish: mech. descaled Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 2 - 3 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: round Material: 1.4034 (X46Cr13) Type of production: hot-rolled Surface: annealed Standard: EN 10088 eClass 9.1: 35010312 UNSPSC 11.2: 30102405 Dimensions: Diameter (mm): 100 Length (mm): 5,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: round Material: 1.4462 (X2CrNiMoN22-5-3) Type of production: hot-rolled Surface: peeled Standard: EN 10088 Tolerance: k13 eClass 9.1: 35010312 UNSPSC 11.2: 30102405 Dimensions: Diameter (mm): 40 - 130 Length (mm): 5,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4301 (X5CrNi18-10) Manufacturing method: cold-rolled, 2R Surface finish: bright annealed Norm: EN 10088-1-2-3 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 0.5 - 3 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500 Factory filming: Standard film, no film, laser protection film

Request for a quoteResults for

Stainless steel rolls - Import exportNumber of results

72 ProductsCountries

Company type