- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel lines

Results for

Stainless steel lines - Import export

CIC - KLAUS CZERWONKA

Germany

Check valves in stainless steel for line installation for demanding applications and high frequencies. Available in sizes 1/8 to 1".

Request for a quote

WUS WILHELM UNGEHEUER SÖHNE GMBH

Germany

Ideal for outdoor use Easy installation through wide opening Connecting thread M10 stainless steel Stainless steel screws We would be very pleased to support you with all your individual questions and suggestions regarding WUS. Give us a ring or leave a message indicating the information you need. We will contact you as quickly as possible. Your WUS team

Request for a quote

GSW SCHWABE AG

Germany

This line of Roller Lubricators will balance strip floating thanks to a springsocketed inner box. Stainless steel housing, flexible pass line and special, individually controllable spray nozzles benefit setup time and operating costs.

Request for a quote

CARL SCHMIDT SOHN GMBH

Germany

Featuring sleek design, and cast in high-grade 18/10 stainless steel, the PRO-X cookware line is absolutely stable, durable and dishwasher-safe. The PRO-X range is suitable for professional chefs and aspiring cooks alike. lts sophisticated and timeless design fits into every kitchen.

Request for a quote

CARL SCHMIDT SOHN GMBH

Germany

Featuring sleek design, and cast in high-grade 18/10 stainless steel, the PRO-X cookware line is absolutely stable, durable and dishwasher-safe. The PRO-X range is suitable for professional chefs and aspiring cooks alike. lts sophisticated and timeless design fits into every kitchen.

Request for a quote

CARL SCHMIDT SOHN GMBH

Germany

Featuring sleek design, and cast in high-grade 18/10 stainless steel, the PRO-X cookware line is absolutely stable, durable and dishwasher-safe. The PRO-X range is suitable for professional chefs and aspiring cooks alike. lts sophisticated and timeless design fits into every kitchen.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Stainless steel is expensive. Verinox offers the same level of quality as the conventional material used for the construction of tanks and containers while using less stainless steel. With Verinox – the duplex material developed by Lipp – a sheet of stainless steel is joined to a sheet of galvanised steel by means of a separation layer. Three components form the basis for this material that is ideal for tank and container construction not only does it have outstanding physical properties but it also uses a reduced quantity of expensive stainless steel, resulting in lower costs. With this invention, Lipp has successfully retained the economic benefit of the LIPP Double Seam System while improving the material savings made. VERINOX ENABLES STAINLESS STEEL TO BE USED INSIDE TANKS – ESPECIALLY WITH MEDIA THAT REQUIRE SUFFICIENT RESISTANCE No open joints due to the folded design Doubly lined in stainless steel with a smooth continuous finish

Request for a quote

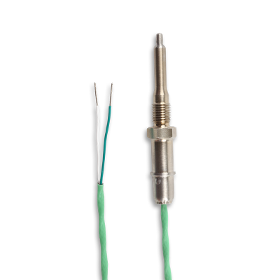

THERMA THERMOFÜHLER GMBH

Germany

This sensor for measuring exhaust gases was developed together with a Formula 1 team. The goal was to achieve the greatest possible reliability during the race. The sensor was designed so that it can withstand a maximum of vibrations and extreme temperatures while being made in a highly compact construction at the same time. The special feature is the connection lead. It is not made from the usual mineral-insulated stainless steel sheathed line, which is too rigid and which tends to vibration fractures. Instead, the line is made of stranded conductors with PTFE insulation and an additional heat shield so it can be easily and flexibly adapted to the environment. The sensor is being used with exceeding success by professional teams in long distance races, American race series and the domestic DTM. The benefits: Highly vibration-proof Very robust High temperature resistance (up to 1,200 °C) Individual plug assembly possible Can be individually adapted

Request for a quote

BDSENSORS GMBH

Germany

The battery-powered BAROLI 02 enables a local displaying of values, satisfying the highest demands for accuracy and long-term stability. The pressure gauge may be applied compatible with the stainless steel used; it shows an excellent robustness and a high overpressure protection. The BAROLI 02 display housing is rotatable, thus ensuring an easy reading even under unfavorable mounting conditions. Additional functions: changing the unit, displaying min / max values, calibrating of offset and the span, configuring the automatic switching-off. Features: — nominal pressure: 0 ... 100 mbar up to 0 ... 600 bar — accuracy: 0.125 % FSO — stainless steel diaphragm — 2-line LC display, 4.5-digit 7-segment display, 6-digit 14-segment additional Display — mechanical connections: inch, NPT threads Optional Features: — min- / max-function with reset function — offset and end point calibration — setting the pressure unit

Request for a quote

BDSENSORS GMBH

Germany

The BAROLI 05P enables a local displaying of values in applications, where high requirements on hygienic process connections and easy cleaning or sterilisability are requested. The filling medium is food compatible oil with FDA approval. The display housing is rotatable, thus ensuring an easy reading even under unfavorable mounting conditions. Additional functions as changing unit, displaying min / max values, calibrating of offset and span, as well as configuring the automatic switching-off complete the profile. Features: — nominal pressure: 0 ... 60 bar up to 0 ... 400 bar — accuracy: 0.25 % FSO BFSL (class 0.2) — flush welded stainless steel diaphragm — rotatable housing — 2-line LC display, 4.5-digit 7-segment display, 6-digit 14-segment additional display — suited for viscous and pasty media Optional Features: — min / max function with reset function — offset and end point calibration

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you idler pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you drive pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

RONIX GMBH

Germany

Hand riveters are essential tools for anyone who needs to join two materials together permanently. These tools work by compressing a metal rivet through two or more layers of material, creating a secure and permanent bond. Hand riveters are used in a wide range of industries, including construction, metalworking, and automotive repair. They are especially useful when working with materials that cannot be easily welded or screwed together. Equipped with 4 heads of different sizes, Ronix RH-1604 is ready to help you in your next repair or maintenance work.

Request for a quote

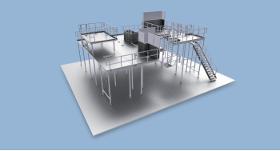

EDELSTAHL WEIMAR GMBH

Germany

Machine, work and operating platforms from stainless steel for aseptic and hygienic application - for example in the food, beverage, pharmaceutical or chemical industry. We offer the complete package including design and static calculation, manufacturing and assembly. We guarantee stainless steel manufacturing quality made in Germany, quick throughput times and competitive pricing. We are your reliable partner for stainless steel platforms and mezzanines!

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan® pipe Bend 90° female/male

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan-ECO pipe 6 m rods

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan Bend 90° M-thread/nut

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan® Bend 90° female/male - long

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan® Full crossover F/F

Request for a quoteResults for

Stainless steel lines - Import exportNumber of results

160 ProductsCountries