- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spraying systems

Results for

Spraying systems - Import export

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® Spintec top loader spray chamber washing systems are the solution for fast parts cleaning in maintenance! The parts to be cleaned are placed in the washing basket of the system from above. During the washing process, cleaning fluid is sprayed onto the parts from below, above and from the sides. The basket rotates inside the machine, resulting in an even washing result. The detergent reservoir is located in the bottom of the machine and is also equipped with a heater.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® VIVERK are single and multi-stage spray chamber cleaning systems for aqueous cleaning, pretreatment and degreasing of tools and parts. Loading takes place via an extendable platform, which can be loaded at an ergonomic working height. The workpieces are mechanically cleaned by means of pump pressure in the spray chamber process. The temperature-controlled washing liquid is sprayed onto the workpiece via a spray frame.The washing plant is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Single and multi-stage spray chamber washing systems for industrial cleaning and degreasing of tools and parts. Loading takes place via an extendable loading platform at ergonomic working height. Before cleaning, the loading basket is loaded and moved into the rinsing chamber. The individual stainless steel washing nozzles can be easily maintained and adjusted according to the application. The motor-driven spraying rotor completely revolves around the loaded parts. The washing system is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

DRESSLER GROUP

Germany

We developed a special process for making fine powder systems and composites from low-viscosity melts. With the patented cryo-spraying process CSP, it has become possible to produce highly sensitive products directly from a hot melt to form a solid powder without after-cooling. The entire spraying process is overlaid with nitrogen and also protects very critical substances against oxidation and thermal stress.

Request for a quote

MANTIS ULV SPRÜHGERÄTE GMBH

Germany

Advantages of MANKAR® ULV spraying systems Very precise, sharp output with a merely minimal risk of drift »saves money while preserving the environment and conserving cultivated plants! Low herbicide comsumption thanks to ULV technology »economical and enviromentally friendly! (up to 80% lower herbicide consumption) Optimal herbicide coverage due to the defined narrow droplet size spectrum »particulary efficient utilisation of the active substance Considerably lower weight due to undiluted application »lower degrees of soil compaction, reduced levels of back strain! No mixing or measuring herbicides and no water needed »saves time! Independent of the water supply source! Drive is by means of rechargeable batteries or vehicle power (DC/DC converter) »low engergy consumption, very quiet! Can be adapted to different areas of applications thanks to a variety of models with variable spray widths. »an optimal spray unit designed precisely for YOUR application needs!

Request for a quote

MSO MESSTECHNIK UND ORTUNG GMBH

Germany

System for spray quality monitoring a multitude of spray nozzles e.g. for agricultural sprayers

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Precise atomisation and spraying can be continuous or selective. The revolutionary combination of continuous flask and low-flow spray chamber guarantees perfect spraying of low to highly viscous media with high edge sharpness and minimum overspray. Fields of activity: - Dosing - Coating - Microsputtering - Lubrication - Marking and much more. Materials: - Fats/oils - Colours - Activators/primers - Abrasive materials - Adhesives - Silicones - Solid-laden materials and much more. Advantages: - Constant quantity/area - Uniform spray pattern - Uniform coating - Little overspray/high edge sharpness - Defined volume per revolution - High chemical resistance - High spread - Adjustable round jet - From dot spraying to continuous spraying - Low-maintenance system - flow rate of the medium and atomising air can be regulated independently - High application efficiency

Request for a quote

A.B.C. WORLDWIDE GMBH

Germany

Disinfectant dispenser with automatic spraying system. with wooden mounting Sensor range 0-12 cm (infrared sensor) Battery life (type AA) 1000 hours (batteries not included) 1000ml filling quantity Quantity per spraying process 1.2 ml Including security key for filling

Request for a quote

MANTIS ULV SPRÜHGERÄTE GMBH

Germany

In the food industry the atomisers and dosing systems of Mantis can be used everywhere where liquids have to applied uniformly and sparingly. This could for example be the application of release agents onto baking trays and dishes or the application of flavouring substances. Don’t hesitate to contact us! We offer an optimally adjusted spraying system also for your application area!

Request for a quote

LALK GMBH &CO. KG

Germany

It has an integrated water spray system that ensures optimal saw blade cooling and immediate disposal of sawdust. Due to the extremely efficient working system the water consumption is low and it complies with current safety standards. Also the saw is very robust because of its welded steel construction. The table pad with non-slip rubber coating is also manufactured with great care and combined with the precisely running, easy-to-use cutting table with adjustable angle stop precise cuts are guaranteed.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Eckardt Umformtechnik GmbH Contact-free lubrication Flexible & clean application Our spray systems apply oils and release agents fully contact-free. Making use of this method you guarantee the medium is applied cleanly and evenly, which allows you to act flexibly if not all areas of a material are to be lubricated uniformly. One huge advantage of our spray systems is their extremely fast changeover times to use different grades of oils. Oil/release agent storage; manual and fully automatic control and monitoring of the spray process. We offer our customers a wide range of options. Features & benefits • Minimum setup times when changing spray medium • Different spray nozzles available • Suitable for all fluid media and numerous oil grades Individual solutions for all application purposes EOS systems are perfectly designed to meet the needs of industry to apply oils and release agents. They are solidly built and exceptionally easy to maintain; they reliably and precisely control

Request for a quote

TECHNO-COMPOSITES DOMINE GMBH

Germany

We have already designed and built an array of different spray protection systems for indoor and outdoor use at industrial plants on behalf of our customers. These traditionally consist of a loadbearing system made of weatherresistant GRP profiles and transparent, weatherresistant plastic panels. The spray protection system has already been enhanced with e.g. fastener frames for electric distributors, pipe supports, GRP cable bushing systems, GRP doors and ports and special openings for sample extraction. As the GRP spray protection systems for outdoor use are also exposed to high wind loads, we are happy to provide auditable static analysis from an independent structural engineering firm to confirm their stability.

Request for a quote

TECHNO-COMPOSITES DOMINE GMBH

Germany

Cover for a salt spray test facility The original plexiglass cover of this salt spray test system needed to be replaced by a new, much sturdier cover. This was designed and manufactured by TC on the basis of GRP profiles and GRP sheet material.

Request for a quote

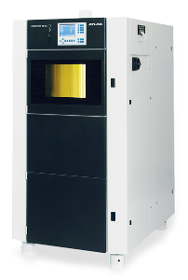

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Xenotest Beta+ is a premium stand-alone rotating rack xenon instrument with 4000cm 2 exposure area. It comes serially with a complete set of parameter controls. Irradiance and temperature are measured and controlled directly on the sample level using on-rack XENOSENSIV sensor technology. Beta+ complies with the vast majority of industry standards. Due to its large test chamber and highly reliable performance, it’s ideal for larger capacities or sample sizes. 3x 2200 W air-cooled Xenon Lamps 4000 cm 2 exposure area High-irradiance testing up to 120 W/m 2 (2 Sun) Touch screen with colour display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400 nm) Direct Setting and Control of Black Standard Temperature Direct Setting and Control of Chamber Temperature Direct Setting and Control of Relative Humidity Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test methods Multilingual User Interface Non-aging XENOCHROME filters to simulate outdoor daylight, daylight behind window On-rack XENOSENSIV 300-400 nm for measuring and controlling irradiance (in W/m 2) and BST (C°) on sample level Selectable Temperature control either by Chamber Temperature (max. 70 °C) or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 130 °C) Fan-controlled temperature difference between Chamber and Black Standard Temperature Ultrasonic humidification system for humidity control Specimen spray system with integrated 60 l water reservoir Outer cylinder made of Special UV glass Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via memory card or RS 232 interface Ethernet interface for connection to internal computer network and use of XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Thermoprinter XenoCal WST White Standard Thermometer XenoCal BST Black Standard Thermometer Rack spray system XenoCal BB 300-400 Irradiance Sensor XenoCal WB 300-800 Irradiance Sensor XenoCal NB 340 Irradiance Sensor

MANTIS ULV SPRÜHGERÄTE GMBH

Germany

Which purpuse are MAFEX-Silage sprayers used for? Mafex-Silage spraying systems ares used for application of liquid silage support agents directly during chaffing. How and where should a MAFEX-Silage sprayer be assembled? Atomisers are installed in protective tubing at an appropriate location with an adapter suited to the chopper. The atomiser cannot clog thanks to its special design and installation angle. On John Deere choppers installation by the accelerator, for example, takes place so that plant parts are evenly covered by the droplets as they are discharged. On the other hand and depending on the year ofmanufacture, atomisers on New Holland choppers are installed near the feed rollers or, likewise, by the accelerator. As a rule, installation is possible on any chopper (e.g. Claas, Krone, etc.). Stationary installations on conveyor systems, for example, are also possible. Advantages Optimisation of the silage process Minimum application volumes Optimal distribution of active ag

Request for a quote

MANTIS ULV SPRÜHGERÄTE GMBH

Germany

MANKAR®-Roll – Wheelbarrow units for comfortable handling in row cultivations Because the spray systems in the MANKAR®-Roll group are pushed like wheelbarrows, they are very nicely suited to handling large areas of in-row cultivation, for example, as well as pathways and plazas with water-bound surfaces. Up-slope and down-slope gradients are no problem thanks to the low unit weights. In 2014 the new MANKAR-TWO and MANKAR-ONE models have been introduced. Like in the former MANKAR-P and -GP models the patented segment rotation atomiser and a wheeldriven pump ensure the path-dependent, exact and economical metering of herbicides. The spray hoods and many of their functionalities are new. There are three spray hoods with various spray widths which can cover spray widths between 25 and 110 cm, depending on the combination and alignment of spray hoods. The assembly of the spray hoods can be either behind or in front of the wheel. Extension arms are also available. The spray hoods flap back

Request for a quote

MANTIS ULV SPRÜHGERÄTE GMBH

Germany

MANKAR® ULV-Spraying Systems MANKAR® systems are professional spraying equipments for the effective, environmentally sound and still economically advantageous weed control with herbicides without water as well as herbicide mixtures. The base on the ULV technology (Ultra Low Volume) which optimally distributes a very low quantity of liquid preparation in small, uniform droplets. Thus the required quantity of herbicides is reduced significantly, e.g. for Roundup® UltraMax by up to 50 % on cultivated areas and up to 80 % on surface with irregular weed infestation. A lot of other advantages make MANKAR® sprayers a profitable investment for professional users. MANKAR® Carry – Hand-held units for the highest degree of flexibility The handheld MANKAR® sprayers are most suitable for use in cultivations which grow very densly and everywhere where maximum flexibility is required. MANKAR® Roll – Hand-pushed units for use in row cultivations and open space The MANKAR®-Roll sprayers are suitable f

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® 340 is a weakly alkaline cleaning agent for grease, oil and oil carbon soiling. Very suitable for pre-cleaning or basic cleaning of soiled steel, cast iron and non-ferrous metal or plastic parts in an ultrasonic bath or in a spray cleaning system. After cleaning and without water rinsing, the parts are temporarily protected against corrosion. The final drying can be accelerated by blowing off with compressed air, a warm air flow or treatment in a drying cabinet. WIWOX® 340 can be used in a concentration of 5 – 7 %. Dilution with water depends on the degree of contamination and the intended exposure time. The bath should have a temperature of approx. 60° C. The bath should be kept at a constant temperature. In the field of precision mechanics, longer exposure times are possible depending on the degree of contamination.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XXL+ FD is a large state-of-the-art xenon flatbed instrument. It’s completely target designed to meet the testing needs of the FMCG industry, such as drinks, foodstuffs, personal care or household products. XXL+ FD enables consumer goods manufacturers to test their products realistically within very short test times, typically with acceleration factors between 10-30 versus real time. It’s for reliable qualification of stable product formulations, determination of appropriate packaging materials, and supporting product shelflife claims. 3x 1700 W air-cooled Xenon Lamps 3000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and Control of Irradiance 300-400 nm / 340nm or 420nm Measurement and Control of Black Standard (BST); (Black Panel optional) Measurement and Control of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Thermal insulation of test chamber and periphery preventing water condensation Temperature control selectable either via CHT (15° * - 70 °C; *with chiller) or via CHT and BST (25° * - 100 °C; *with chiller) simultaneously (dual control) Adapted chiller SunCool XXL+ for testing at low temperatures in the range 15-30°C CHT; detachable for standard weathering testing needs Ultrasonic humidification system for controlled humidity during operation without SunCool Specimen spray system with integrated 60 l water reservoir for spray cycles at 25°C ** - 70°C Static, horizontal exposure area for flat or 3D specimen Test chamber with 5 ° slope for optimum spray water drain Access port ca. 3,0 x 2,5 cm for potential use of additional external sensors inside the test chamber Light cassette including non-ageing aluminium reflector, coated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Sliding sample table for easy specimen loading; exposure area (WxD) 74 x 37 cm

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XXL+ is a large state-of-the-art xenon flatbed instrument. The 3000 cm2 test chamber is perfect for high volume weathering testing of large flat or 3-D specimen. SUNTEST XXL+ offers a complete set of features ideal for standard testing covering all common industry weathering standards. 3x 1700 W air-cooled Xenon Lamps 3000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and control of Irradiance 300-400 nm / 340nm or 420nm Measurement and control of Black Standard (BST); (Black Panel optional) Measurement and control of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Ultrasonic humidification system for humidity control Specimen spray system with integrated 60 l water reservoir Static, horizontal exposure area for flat or 3D specimen Test chamber with 5 ° slope for optimum spray water drain Access port ca. 3,0 x 2,5 cm for potential use of additional external sensors inside the test chamber Light cassette including non-ageing aluminium reflector, coated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Various specimen holders to hold different panel sizes. XenoCal sensors to calibrate BST and irradiance. Large variety of filter systems: coated and uncoated quartz, special UV glass, daylight filter, window glass, Solar ID 65, Solar Standard, to meet various spectral specifications in standards.

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

Xenotest Alpha+ is a compact stand-alone rotating rack xenon instrument with 1320cm 2 exposure area. It comes serially with a complete set of parameter controls. Irradiance and temperature are measured and controlled directly on the sample level using on-rack XENOSENSIV sensor technology. Alpha+ complies with the vast majority of industry standards setting the benchmark in narrow tolerance testing. Due to its highly reliable performance, it’s often chosen by R&D departments or commercial Service Test Houses. 1x 2200 W air-cooled Xenon Lamp 1320 cm 2 exposure area High-irradiance testing up to 180 W/m 2 (3 Sun) Touch screen with colour display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400nm) Direct Setting and Control of Black Standard Temperature Direct Setting and Control of Chamber Temperature Direct Setting and Control of Relative Humidity Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test methods Multilingual User Interface Non-aging XENOCHROME filters to simulate outdoor daylight, daylight behind window glass On-rack XENOSENSIV 300-400 nm for measuring and controlling irradiance (in W/m²) and BST (C°) on sample level Selectable Temperature control either by Chamber Temperature (max. 70 °C), or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 130 °C) Fan-controlled temperature difference between Chamber and Black Standard Temperature Ultrasonic humidification system for humidity control Specimen spray system with integrated 60 l water reservoir Specimen holder carousel for 11 specimen holders Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Thermoprinter XenoCal BST Black Standard Thermometer XenoCal WST White Standard Thermometer XenoCal BB 300-400 Irradiance Sensor XenoCal WB 300-800 Irradiance Sensor XenoCal NB 340 Irradiance Sensor Turning mode programmable

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Xenotest 440 is a highly versatile xenon weathering instrument for a variety of materials. Designed for fast and economical testing, the Xenotest 440 utilizes XenoLogic™, a revolutionary new twin-lamp operating technology which enables high irradiance levels of 120 W/m 2 of total UV radiation. In addition, XenoLogic provides extended lamp service life. With this new technology, the two xenon lamps combined can last over 4000 hours under standard testing levels of 40-60 W/m 2. 2 x 2200W air-cooled xenon lamps 2310 cm 2 exposure area XenoLogic TM lamp operating technology for extended lamp service life Touch screen with color display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400 nm) Direct Setting and Control of Black Standard Temperature (BST) Direct Setting and Control of Chamber Temperature (CHT) Direct Setting and Control of Relative Humidity Display of Diagnostic Messages Storage for 10 user-defined tests Multi-Language Capability: English, German, Italian, French, Spanish, Turkish, Dutch, Polish, Hungarian, Czech, Japanese, Korean, Chinese On-rack XENOSENSIV® RC-34 BST for measuring and controlling irradiance (in W/m²) in the wavelength range 300-400 nm and BST (°C) on specimen level Selectable temperature control either by Chamber Temperature (up to 65 °C) or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 115 °C) simultaneously Fan-controlled temperature difference between BST and CHT Ultrasonic humidifier controlling relative humidity in the range 10-75% (Light cycle) Integrated 60 litre water reservoir for humidity control and specimen spray (automatic refill) Specimen spray system Rotating specimen rack with 38 test positions (13.5 cm x 4.5 cm); 33 (10.0 cm x 6.8 cm); 22 (13.5 cm x 5.5 cm); 11 (29.5 cm x 7.0 cm) Pre-programmed lightfastness and weathering standards Outer cylinder made of special UV glass UV-protected test chamber window Internal memory chip for storing instrument data Data output via Memory Card or serial interface RS232 Ethernet interface for XenoTouch Add-ons (Remote Control, E-Mail Service, Online Monitoring) XENOSENSIV RC-420 BPT

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For highest contact pressure and high circumferential speed, e.g. for rotary kilns, ball mills, rotary barrel mixers, ball mills, rope winches or friction presses also for guiding elements, slide bars, heavy transport chains and closed wire ropes Lubrication of rotating assemblies of convertors, cranes, crushers and dredges with spray or central lubricating systems Lubrication of heavily loaded gear couplings Advantages and benefits Most suitable for reliable supply of open gears, even at high circumferential speed Very efficient through EP additives in association with a specific combination of solid lubricants and adhesive additives Reliable protection of tooth flanks, even at high temperatures and with extended relubrication time Good pressure resistance of the lubricating film, excellent wear protection The film is not embrittling and aging. Without bitumen, solvent, does not contain heavy metals

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of fast-running drive chains of all designs for open or semi-open operation without a permanent re-lubricating device, such as motorcycle and bicycle chains Lubrication of hoisting chains such as multirow roller chains or stacker truck chains, as well as single or multiple flat-link articulated chains Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Extreme adhesive strength Extreme wear protection through Moₓ-Active additive Very high resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral For best adhesion, clean the surfaces mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 340 with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Spray on evenly OKS 341 spray. Allow excess to drip off and wait for lubricant to penetrate before resuming operation.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of fast-running drive chains of all designs for open or semi-open operation without a permanent re-lubricating device, such as motorcycle and bicycle chains Lubrication of hoisting chains such as multirow roller chains or stacker truck chains, as well as single or multiple flat-link articulated chains Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Extreme adhesive strength Extreme wear protection through Moₓ-Active additive Very high resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral Also available as spray version OKS 341 For best adhesion, clean the surfaces mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 340 with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Spray on evenly OKS 341 spray. Allow excess to drip off and wait for lubricant to penetrate before resuming operation.

Request for a quote

PRESSTA EISELE GMBH

Germany

Double mitre saw with a fixed unit on the left and the other one movable. Automatic positioning of the movable unit. Electronic positioning of the cutting units on any angle within 22,5° and 135°. Realized with cutting lenght of 4000 mm (7650 mm with accessories), 5000 mm (9650 mm with accessories), 6000 mm (11650 mm with accessories). It is equipped with the system EC 700x. Electro-welded sheet base which has been designed in such a way to offer the maximum rigidity and use practicality. Frontal and straight blade feed with speed adjustments. Hydro-pneumatic blade feed. Wide cutting capacity by means of sawblades Ø 450 mm. Possibility to use a blade with a dia. 500 mm, only by eplacing the tool. Dynamic protection guards for a total covering of the cutting area. Mist spray lubrication tools (Venturi system). Pre-arranged to connect an exhaust extractor for swarfs. Pre-arranged to use a set of tanks to collect swarfs. Pre-arranged to connect a motorised belt conveyor.

Request for a quote

PRESSTA EISELE GMBH

Germany

Double mitre saw with a fixed unit on the left and the other one movable. Automatic positioning of the movable unit. Pneumatic tilting of the heads (90°, 45° or 22,5°). The intermediate degrees can be obtainedby manually setting mechanical stops. Realized with cutting lenght of 4000 mm (7650 mm with accessories), 5000 mm (9650 mm with accessories), 6000 mm (11650 mm with accessories). It is equipped with the system EC 609. Electro-welded sheet base which has been designed in such a way to offer the maximum rigidity and use practicality. Frontal and straight blade feed with speed adjustments. Hydro-pneumatic blade feed. Wide cutting capacity by means of sawblades Ø 450 mm. Possibility to use a blade with a dia. 500 mm, only by eplacing the tool. Dynamic protection guards for a total covering of the cutting area. Mist spray lubrication tools (Venturi system). Pre-arranged to connect an exhaust extractor for swarfs. Pre-arranged to use a set of tanks to collect swarfs. Pre-arranged...

Request for a quote

PRESSTA EISELE GMBH

Germany

Double mitre saw with a fixed unit on the left and the other one movable. Manual positioning of the movable unit. Pneumatic tilting of the heads (90°, 45° or 22,5°). The intermediate degrees can be obtainedby manually setting mechanical stops. Realized with cutting lenght of 4000 mm, 5000 mm, 6000 mm. It is equipped with the system EC 601. Electro-welded sheet base which has been designed in such a way to offer the maximum rigidity and use practicality. Frontal and straight blade feed with speed adjustments. Hydro-pneumatic blade feed. Wide cutting capacity by means of sawblades Ø 450 mm. Possibility to use a blade with a dia. 500 mm, only by eplacing the tool. Dynamic protection guards for a total covering of the cutting area. Mist spray lubrication tools (Venturi system). Pre-arranged to connect an exhaust extractor for swarfs. Pre-arranged to use a set of tanks to collect swarfs. Pre-arranged to connect a motorised belt conveyor.

Request for a quote

REA ELEKTRONIK GMBH

Germany

The REA JET One Dot Systems (EDS) are particularly well suited to very fine dot and line markings. The dot size is configured by selecting the nozzle size and by varying the material pressure, and the stepless setting on the controller. Applications — for quality assurance you can mark products with a dot to be recognized as either good or bad (use automatic camera recognition) — colored line marking for pipes, profiles and endlessly manufactured products (e.g. extruded goods) — applying oils, separating agents, soaps or process water — welded seam marking in the manufacturing of metal profiles — applying fragrances to cosmetic samples

Request for a quoteResults for

Spraying systems - Import exportNumber of results

66 ProductsCountries

Company type

Category

- Sawing machine tools (6)

- Sandblasting equipment (3)

- Silicones (3)

- Marking machines (1)

- Paint spray guns and accessories (1)

- Automatic dispensers (1)

- Cutting - steels and metals (1)

- Dosing pumps (1)

- Inductive sensors (1)

- Industrial sheet metal work (1)

- Metals - Machines & Equipment (1)

- Plastic material processing (1)

- Precious and semiprecious stones and pearls (1)

- Rails and sliding frames (1)

- Sheet metal and strips, tinplate (1)

- Varnishing - steels and metals (1)