- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spray drying

Results for

Spray drying - Import export

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of open pinion gears which are highly subject to wearing due to corrosion and continuous soiling, e.g. on construction machines, spindle presses, crushers, mills, windlasses, rubbish disposal devices, ship´s lifting jaws or water structures Wire cables subject to outdoor weathering, e.g. on crane systems, lifts and aerial tramways, ship´s and offshore equipment for diverse types of sealing lubrication, including of coarse chains and chain transporters Advantages and benefits Highly effective due to outstanding wetting and lubricating properties Decreased friction and wear, and therefore reduction of necessary repair times Economical due to thrifty consumption as a result of small application quantities and time-saving use due to advantageous spray form Dry, elastic film with high adhesive strength prevents adhesion of dust and dirt Waterproof and has good corrosion protection properties

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Run-in lubrication in combination with oil or grease lubrication Dry lubrication at sliding pairs, in particular under heavy loads and low sliding speeds, at oscillating movements or intermittent operation Dry lubrication at high operating temperatures (up to 450°C), shorter sliding paths and low speeds Dry lubrication in dusty environment, to avoid adhesions Coating of punching tools Advantages and benefits Highly effective due to good adhesion to prepared substrates Allows a low coefficient of sliding friction also under heavy loading Increased wear protection Radiation and vacuum-resistant Shortens and improves run-in conditions of friction bearings, toothings and other sliding pairs

Request for a quote

LIENIG WILDFRUCHTVERARBEITUNG GMBH

Germany

Aronia paste Finely strained, all valuable ingredients of the aronia fruit are preserved Aronia mother syrup Carefully processed pressed juice Aronia fruit juice concentrate clear/naturally cloudy Through careful vacuum evaporation the residual moisture level is reduced to 35%. Especially suitable for base materials, food supplements, beverages and natural products. Aronia powder It is made from "fruit juice concentrate" and contains all valuable ingredients of the aronia fruit. By way of gentle spray-drying a fine powder is obtained.

Request for a quote

LIENIG WILDFRUCHTVERARBEITUNG GMBH

Germany

Sea buckthorn fruit pulp oil contains an especially high level of carotin and palmitoleic acid - a component of skin fat. Sea buckthorn paste All valuable ingredients (A, B, C, E, as well as essential vitamins) of the refined sea buckthorn paste are preserved. The paste exhibits a high natural viscosity which ensures a very stable turbidity. Sea buckthorn fruit juice concentrate clear/naturally cloudy Through careful vacuum evaporation the residual moisture content is reduced to 35 - 50%. Especially suitable for base materials, sweets and honey! Sea buckthorn powder It is produced from paste and contains all valuable ingredients of the sea buckthorn fruit. By means of gentle spray drying a fine, bright orange powder is obtained, with an oil content of up to 15%. Sea buckthorn grape marc Its special feature is a high content of natural essential fatty acids and vitamin E (tocopherol). Sea buckthorn kernel oil Pure sea buckthorn mother syrup

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Foam for cleaning and maintaining whiteboards. Anti-drip after spraying on. • Foam cleaner for whiteboards • No running after spraying on • Suitable for dry-erase whiteboard markers • Can be used, for example, with DRY CLEAN wipes product # 5734 • Contents: 400 ml

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The coaters series type LC were specifically developed for coating tablets. With our coater range, Loedige is one off the technological market leader. The maximised tablet bed surface in the Lödige coater and the maximum number of spray nozzles mean that extremely high liquid volumes can be applied with extremely high air supply volumes within a very short time. The newly designed, particularly low-turbulence air routing ensures a highly efficient and gentle use of dryer air. These features ensure a reliable coating process and short process times. Moreover, the low-turbulence air routing prevents contamination from the very start, thereby reducing the cleaning workload. Modern sensors permit optimisation of the spraying and drying process. Simple yet secure nozzle arm adjustment makes for easier handling.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

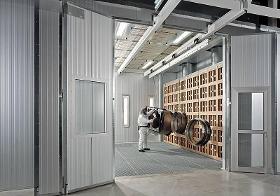

Spray walls and spray booths with dry separation via cartons. For lower utilisation times or overspray quantities RES dry spray booth For lower utilisation times or smaller overspray quantities, spray systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RES enables individual adaptation to the respective case of need. The filter system of the RES dry spray wall consists of individual square cardboard boxes. A sheet metal frame serves as a support structure for the filter box. In order to save costs, there is a possibility to vary the individual filter boxes in the spray booth, without exchanging all of the filter elements. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The basic version consists of a wall with a two-fold filter stage. Paper filter boxes form the first filter stage. A glass fibre fine filter arranged directly behind it represents the second filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The spray booth can additionally be equipped with removable or fixed side and ceiling panels. The RES dry spray booth is available in galvanised sheet metal or in stainless steel. Advantages Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. Once it is saturated, the filter box is removed from the sheet metal frame and disposed of in an environmentally-friendly manner.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Standard advantages: RTS-Rotation – low-maintenance dry spray booth Overspray dry separation demonstrates its strengths in practice above all when relatively large quantities of paint have to be processed and the overspray portion cannot be reduced any further. Spray booth with dry separation are usually equipped with disposable filters or manually regenerative filters. These cause costs for spare filters, maintenance and disposal. In addition to that, operation has to be interrupted in order to exchange the filters. The ‘RTS rotation’ system was developed by Rippert in order to reduce these costs and tooling times. Maintenance intervals and filter service lives are prolonged significantly in comparison with conventional systems due to the new brush pre-filtration. How the ‘RTS-Rotation’ system works Overspray separation in the RTS-Rotation system takes place by means of a pre-filter and a fine filter stage. The pre-filter stage is formed by vertical, slowly rotating brush rollers. The bristles present a very large total surface area and absorb the adhesive particles from the overspray. During the slow rotation, the paint particles can dry on the tips of the bristles. This results in slowly growing cakings on the bristles. Scrapers are mounted in the area behind the brush rollers that continuously remove these cakings from the bristles. The dislodged, hardened material falls into the drawers arranged under the brushes and can thus be simply disposed of. The dry paint dust may often be disposed of as ‘commercial waste’. The brushes otherwise require little maintenance and do not need to be exchanged or renewed. The fine filter stage is formed by a special fleece filter, which is arranged above the brush rollers and must be manually maintained or exchanged in the standard version. The maintenance intervals depend on the paint material used. Automatic cleaning or an external fine filter with automatic cleaning is also possible as an option. Over 10 years of operational experience shows that around 75 to 95% of the overspray is separated out by the pre-filter stage and the rest by the fine filter stage. The degree of separation depends strongly on the type of paint and the drying reactivity during the flying phase. Use of the RTS-Rotation with the following paints Before practical use, the paints are tested and approved in Rippert’s own pilot plant. Stove enamels and 100% UV paint systems cannot be used. The horizontal version Furthermore, it is possible to use the system as a horizontal underfloor extraction system. This version is used, for example, by a machine manufacturer for large parts. In addition, a drag conveyor with gulley extraction is used there in order to automatically transport the particles cleaned off the brushes out of the pit. Conclusion The RTS-Rotation system is particularly useful when relatively large quantities of paint with an unavoidable overspray portion have to be processed, as otherwise a great deal of residual waste would result using conventional technology. Compared to water-sprinkled spray walls and normal dry spray booths the amortisation period is shorter; it is frequently less than two years.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

The modular manual spray lances were developed for simple spraying requirements in the forging and die-casting industry. Compact design, easy to handle and with the 2-step trigger ideal for spraying and dry blowing The large selection of spray lances and nozzles allows an optimal adjustment of the spray mist for your requirements. Due to the robust design of our manual spray lances, continuous operation over years is no problem.

Request for a quote

PERO AG

Germany

The TWT combines a number of cleaning methods in a single unit. Through immersion any spray cleaning with alkaline, neutral or slightly acidic aqueous media, it caters for a wide range of parts and meets even the most stringent requirements regarding technical cleanliness. The cleaned parts are dried under vacuum for extra fast processing. All machine components that come into contact with media are made in stainless steel, allowing for the use of fresh and demineralised water.

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Drying Drying systems for granulates and powder Whether surface moisture, capillary moisture or crystal humidity – each product has its own requirements of the drying. The following applies: With Ebbecke Verfahrenstechnik AG your contract drying is in the best of hands, because we dry granulates and powder carefully according to the specific requirements. On request we can even develop new and innovative drying processes for you. System diversity as a basis for a perfect result With the selected drying process, our process engineers take into account for example the temperature sensitivity, resistance to ultraviolet radiation (infrared radiation), the surface structure and the capillary structure of the product which is to be dried. Of course, the differences in the output moisture content and the desired residual moisture must be included in the procedural evaluation of an efficient drying. However, not every drying system is suitable for every material which is to be dried. To get

Request for a quote

MAHLTECHNIK GÖRGENS GMBH

Germany

Field of applications TurboRotor-system: - Micronisation - Grinding of heat sensitive products - Simultaneous grinding and drying - Simultaneous grinding and spray drying - Selective grinding - Grinding, Mixing or Coating

Request for a quote

MAHLTECHNIK GÖRGENS GMBH

Germany

Field of applications TurboRotor-system: - Micronisation - Grinding of heat sensitive products - Simultaneous grinding and drying - Simultaneous grinding and spray drying - Selective grinding - Grinding, Mixing or Coating

Request for a quote

MAHLTECHNIK GÖRGENS GMBH

Germany

Field of applications TurboRotor-system: - Micronisation - Grinding of heat sensitive products - Simultaneous grinding and drying - Simultaneous grinding and spray drying - Selective grinding - Grinding, Mixing or Coating

Request for a quote

MAHLTECHNIK GÖRGENS GMBH

Germany

Field of applications TurboRotor-system: - Micronisation - Grinding of heat sensitive products - Simultaneous grinding and drying - Simultaneous grinding and spray drying - Selective grinding - Grinding, Mixing or Coating

Request for a quote

MAHLTECHNIK GÖRGENS GMBH

Germany

Field of applications TurboRotor-system: - Micronisation - Grinding of heat sensitive products - Simultaneous grinding and drying - Simultaneous grinding and spray drying - Selective grinding - Grinding, Mixing or Coating

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAHLTECHNIK GÖRGENS GMBH

Germany

Field of applications TurboRotor-system: - Micronisation - Grinding of heat sensitive products - Simultaneous grinding and drying - Simultaneous grinding and spray drying - Selective grinding - Grinding, Mixing or Coating

Request for a quoteResults for

Spray drying - Import exportNumber of results

19 ProductsCountries

Company type