- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- split housing

Results for

Split housing - Import export

IDG-DICHTUNGSTECHNIK GMBH

Germany

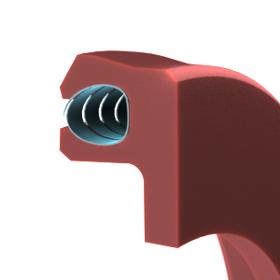

High termat or chemical specifications. Medium pressure and low speed. Suitable for almost all fluids. Robat axes, Rotary unions.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Types 231 to 238 are used for lubricating fluids and to a limited degree also for dry running and purely rotary or oscillating motion. They are only partly suitable for helical motion.

Request for a quote

IGUS® GMBH

Germany

igubal® pillow block bearing, mm/inch Dimensional series K in mm and inch dimensions igubal® pillow block bearing, mm/inch igubal® pillow block bearing KSTM-GT Dimensional series K, large dimensions igubal® pillow block bearing KSTM-GT igubal® pillow block bearing ESTM Dimensional series E igubal® pillow block bearing ESTM igubal® pillow block bearing ESTM-SL Dimensional series E, narrow dimensions igubal® pillow block bearing ESTM-SL igubal® pillow block bearing AD-01-ESTM Adapter for pillow block bearings of dimensional series E igubal® pillow block bearing AD-01-ESTM igubal®- pillow block bearing ESTM-GT..-GT Dimensional series E with split housing and split ball igubal®- pillow block bearing ESTM-GT..-GT igubal® pillow block bearing ESTM-GT igubal® pillow block bearing ESTM-GT with cylindrical bore igubal® pillow block bearing ESTM-GT igubal® pillow block bearing ESTM-GT150 igubal® ESTM-GT150 - Large pillow block bearing with gliding layer for diameters up to 150 mm. igubal® pillow block bearing ESTM-GT150 Maintenance-free, self lubricating High stiffening High fatigue strength in varying loads Compensation for alignment errors Compensation of edge loads Corrossion-resistant Chemical resistant High dampening qualities Suitable for rotary, oscillating and linear movements Very low weight High radial loads Usable in media Space saving Easy to fit Life time predictable Maintenance- and lubrication-free igubal® pillow block bearings are very easy-to-mount bearing elements which compensate for errors and prevent misalignments. Application area igubal® pillow block bearings ideally compensate for shaft misalignments, tilts and bends through their spherical adjustability. Main application areas are wherein such effects should not hinder special designs. igubal® pillow block bearing - Applications Tolerances Maintenance-free igubal® pillow block bearings have a tolerance in the inner diameter, according to E10. The shaft should have a tolerance between h6 and h9. The bearing clearance compensates for bearing expansions during heating. Installation igubal® pillow block bearings are designed to be fastened with 2 screws. A precise alignment of the bearing housing is not required as the spherical bearing automatically compensates for error. Delivery program igubal® pillow block bearings are available in the dimensional series K and E for shaft diameters from 5 to 50 mm. The dimensional series K is also available in inch dimensions. Please ask us for other dimensions. When to use it? When chemical resistance is required When a low-cost alternative is desired When dirt-resistant bearings are needed When misalignments should be compensated When fully split components are needed When not to use? When temperatures above +80°C prevail When an integrated collar is required When dimensions over 50 mm are needed When rotation speeds in excess of 0,5 m/s should be implemented igubal® pillow block bearing, mm/inch Dimensional series K in mm and inch dimensions igubal® pillow block bearing, mm/inch igubal® pillow block bearing KSTM-GT Dimensional series K, large dimensions igubal® pillow block bearing KSTM-GT igubal® pillow block bearing ESTM Dimensional series E igubal® pillow block bearing ESTM igubal® pillow block bearing ESTM-SL Dimensional series E, narrow dimensions igubal® pillow block bearing ESTM-SL igubal® pillow block bearing AD-01-ESTM Adapter for pillow block bearings of dimensional series E igubal® pillow block bearing AD-01-ESTM igubal®- pillow block bearing ESTM-GT..-GT Dimensional series E with split housing and split ball igubal®- pillow block bearing ESTM-GT..-GT igubal® pillow block bearing ESTM-GT igubal® pillow block bearing ESTM-GT with cylindrical bore igubal® pillow block bearing ESTM-GT igubal® pillow block bearing ESTM-GT150 igubal® ESTM-GT150 - Large pillow block bearing with gliding layer for diameters up to 150 mm. igubal® pillow block bearing ESTM-GT150

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

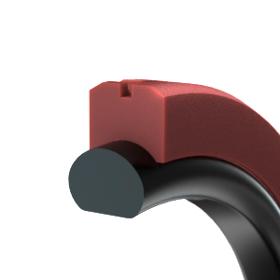

Design of the housing in the form of a groove should be avoided if possible. If this is not feasible, good housing and seal cleanability must be guaranteed. The hygienic design requirements can be met by having a particularly large groove base radius, avoiding notches and having a split housing. For WIP/WOP cleaning it is important to be able to remove and replace the seal without damaging it. Given a suitable machine design, cleaning in place is also possible.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Design of the housing in the form of a groove should be avoided if possible. If this is not feasible, good housing and seal cleanability must be guaranteed. The hygienic design requirements can be met by having a particularly large groove base radius, avoiding notches and having a split housing. For WIP/WOP cleaning it is important to be able to remove and replace the seal without damaging it. Given a suitable machine design, cleaning in place is also possible.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

-20Bild0358f5d1f62a4718.82_4d26c671.jpg)

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Correctly processed residual wood and waste wood constitute a valuable raw material. The Impact Hammer Mill, series PHPS converts pre-shredded residual wood and waste wood of any kind into valuable raw material for material and thermal recovery. Even contaminated materials can be processed. Heavy foreign objects in the feed material are separated and automatically discharged. Characteristics, Function Material feeding is vertically from above Heavy, rotating hammers break the material and throw it against the impact plates The wood is split along the grain and enclosed metal contaminants are set free, separated and discharged Further processing of the wood pieces is effected by stationary breaker and comb bars The end fineness is determined by the perforation of the integrated screen Split housing design allows hydraulic opening Sturdy disc rotor is stress-relieved Adjustable separation degree of the discharge chute for metal pieces Device for hydraulic hammer...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The Impact Hammer Mill, series PHPH ''Grizzly®'' was developed for the economical size reduction of residual- and waste wood of any kind. Not only pre-broken waste wood but also non precut, long recycling wood can be introduced into the mill. The machine distinguishes itself by high throughput rates at low specific energy consumption, low operating costs as well as robust and durable design. Any wood prepared with the „Grizzly®“ is used as a high quality and uniform raw material for material and thermal recovery. Characteristics, Function Material is fed horizontally from the front Size reduction is performed by impact and breaking combs and breaking ledges arranged behind the rotor Collection device for larger foreign objects which can be hydraulically opened for emptying Robust, wear-resistant and multi-split housing which can be easily opened via a hydraulic system Machine parts in the size reduction area made from wear-resistant and durable materials Oscillating hammers...

Request for a quote-20Bild0358f5d1f62a4718.82_4d26c671.jpg)

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Correctly processed residual wood and waste wood constitute a valuable raw material. The Impact Hammer Mill, series PHPS converts pre-shredded residual wood and waste wood of any kind into valuable raw material for material and thermal recovery. Even contaminated materials can be processed. Heavy foreign objects in the feed material are separated and automatically discharged. Characteristics, Function Material feeding is vertically from above Heavy, rotating hammers break the material and throw it against the impact plates The wood is split along the grain and enclosed metal contaminants are set free, separated and discharged Further processing of the wood pieces is effected by stationary breaker and comb bars The end fineness is determined by the perforation of the integrated screen Split housing design allows hydraulic opening Sturdy disc rotor is stress-relieved Adjustable separation degree of the discharge chute for metal pieces Device for hydraulic hammer...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The Impact Hammer Mill, series PHPH ''Grizzly®'' was developed for the economical size reduction of residual- and waste wood of any kind. Not only pre-broken waste wood but also non precut, long recycling wood can be introduced into the mill. The machine distinguishes itself by high throughput rates at low specific energy consumption, low operating costs as well as robust and durable design. Any wood prepared with the „Grizzly®“ is used as a high quality and uniform raw material for material and thermal recovery. Characteristics, Function Material is fed horizontally from the front Size reduction is performed by impact and breaking combs and breaking ledges arranged behind the rotor Collection device for larger foreign objects which can be hydraulically opened for emptying Robust, wear-resistant and multi-split housing which can be easily opened via a hydraulic system Machine parts in the size reduction area made from wear-resistant and durable materials Oscillating hammers...

Request for a quoteResults for

Split housing - Import exportNumber of results

10 ProductsCountries

Category