- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spindle units

Results for

Spindle units - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Cost-efficient transport between floors The vehicle lift CARRICO is an interesting alternative to the TRAFFICO when lower lifting heights and less frequent use are needed. The CARRICO has been type-tested in accordance with the EU Machinery Directive 2006/42/EC. The conveying speed is limited to 0.15 m/s. Furthermore, this car lift is delivered with automatic sliding doors and cabin equipment designed for the transport of vehicles and passengers. Functions of the components Door type: automatic sliding door (depending on the cabin width - 4- or 6-leaf) Entrances: front only / through Control: Control unit with micro-processor with extensive control functions Drive: Submersible hydraulic unit incl. screw spindle pump Advantages Saves on construction space as no ramp required Especially suitable for narrow shafts Cost-effective way to transport cars Easy to operate, manual hinged doors

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

PRESSTA EISELE GMBH

Germany

Base 3000 mm, with hardened guides in x-direction, 3.000 – 8.000 mm Electric device – operation via 2-hand safety control, setting mode to adjust drilling depth – key switch Drilling units with stand and linear guides in X-direction, shafts for manual adjustment of drilling height, working range 125 mm (drill to back wall), Positioning in X and Y direction by scale, Profile height max. 200 mm Either toothed drill chucks or multy spindle heads available Drilling units, motor 1,5 KW, 400 V, 50 Hz, 3000 r.p.m., pneumatic down feed max. 200 mm, hydraulic damped Drilling performance up to Ø 16 mm Zero-stop for X-direction mounted on left side of machine, adjustable 0 – 100 mm Table with pneumatic horizontal profile clamps

Request for a quote

SPINDEL- UND LAGERUNGSTECHNIK FRAUREUTH GMBH

Germany

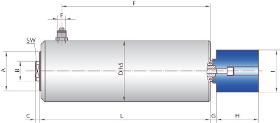

One of the most significant and functionally important components of working machines is their spindle unit. It operates as guidance and drive of tool respectively work piece. It is very important that its function is fulfilled precisely. As a manufacturer of a wide range of machining spindle units naturally short-term maintenance and repairs belong to our service package. In addition to repair of our own products we are also able to repair spindle units with bearings made by other manufacturers. Examination on receipt / disassembling Quotation Rework / remanufacture Assembly Test run Test certificate

Request for a quote

STARRAG GMBH

Germany

The Bumotec s1000 C horizontal transfer machine was designed to manufacture prismatic parts from round or profiled bar stock. Small and complex components can be efficiently machined in medium to large batch sizes. The machine is configured with seven 4axis machining stations, each equipped with 4 machining spindles (2 horizontal and 2 vertical). The eight stations comprise a 4axis cut off station with a single spindle. An optional ninth station allows the component to be reclamped to allow the sixth side of the component to be machined with an additional 3axis, 3 or 4 spindle machining unit. The machine is equipped with an automatic bar feed and quick change tool clamping system for optimum production rates. Features 9 machining stations Up to 36 tools integrated into the machine

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FISCHER FORTUNA GMBH

Germany

mit hybrid spindle bearings and lifetime grease lubrication. Hybrid bearings with steelrings and ceramic balls ensure high lifetime and speed. The spindle is maintenance-free and requires no external service unit. The spindle nose air labyrinth seal reliably protects the bearings against the ingress of contamination and coolant. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories for the HJN860 in the web shop.

Request for a quote

FISCHER FORTUNA GMBH

Germany

with hybrid spindle bearings and lifetime grease lubrication. Hybrid bearings with steelrings and ceramic balls ensure high lifetime and speed. The spindle is maintenance-free and requires no external service unit. The spindle nose air labyrinth seal reliably protects the bearings against the ingress of contamination and coolant. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories for the HJN842 in the web shop.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Reducing operating time and downtime Bring together uniform or diverse processing operations to reduce operating times (usually involves multi-spindle heads). The potential applications are virtually limitless: Drilling, threading, counterboring, reaming, milling, etc. The variety of products is equally diverse, from small compact heads with two spindles to multi-spindle XXL units. BENZ offers interchangeable and fixed-flange (stationary) multi-spindle heads in a wide range of configurations. Multi-spindle heads are typically used for mid-size to large-scale series production. We work in close coordination with you, the customer, to find the perfect solution for your application. Using proven standard components as a basis, we create the optimal multi-spindle solution for you. We maintain close contact with leading machine building companies, giving us the necessary expertise to develop the extraordinary. Give us a challenge!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quoteResults for

Spindle units - Import exportNumber of results

15 ProductsCountries

Company type