- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- speed quality

Results for

Speed quality - Import export

MICRO-EPSILON

Germany

The quality of electrode film is crucial for increasing the performance of future battery generations. In order to generate higher energy densities, coating and calendering processes must be performed with the highest precision. Micro-Epsilon offers high-precision measuring systems for the thickness measurement of coated and uncoated battery film. These systems are equipped with high-resolution sensors and increase process stability, production speed and quality in modern coating lines.

Request for a quote

SCHOLPP GMBH

Germany

Complete installation: services for machinery manufacturers. One part of our services is performing the same installation processes again and again, or complete installations of similar machinery by one manufacturer. To maximize speed, efficiency and quality, we familiarize one or several teams with the specific characteristics of your machinery. This means we are ideally placed to support your staff all the way from disassembly, through transport, to ensuring production readiness. Depending on the task in hand, we assemble interdisciplinary teams with specialists from a variety of fields, including mechanical engineering, mechatronics, electronics, and electrical engineering. And we carefully select equipment, with the best interests of your machines in mind. We guarantee that your machinery will be lifted at the correct points and be up and running as soon as possible. SCHOLPP can train one or more teams on the specific characteristics of your machinery on request.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper PU molded timing belts (form belts), which are cast in special molds, are made of abrasion-resistant polyurethane and high-strength steel cords (or aramid cords). The cast PU timing belt is an exact replica of its mold. Consequently, high pitch accuracy along the entire length of the belt is realized. They are particularly well suited for smooth running and high speeds. By combining high-quality materials and this modern production method, the resulting timing belts exhibit supreme mechanical, chemical and physical properties. Mechanical properties: Low longitudinal tolerance Longitudinal stability, negligible elongation Form-fit, synchronous running Low noise High abrasion resistance Favorable performance-weight ratio Chemical properties: Good ageing resistance Operating temperature range from -30°C to +80°C Resistant to simple oils, greases and gasoline Applications All types of drives Office machines Textile machines Wood-processing machines

Request for a quote

FORBO SIEGLING GMBH

Germany

The Siegling Blizzard HC is a new benchmark in quality and speed when heating splices for Siegling Extremultus belts in the aramide and polyester lines as well as narrow Siegling Transilon belts. It’s easy to handle and has very short cycles. Automatic heating and cooling in one single tool prevents mistakes made during handling saves having to put the belts and splicing guide into a cooling clamp after heating is highly efficient due to short cycles delivers excellent splicing results with superior repeat accuracy

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Based on our many years of experience in developing and manufacturing high-quality machine components, GMN has specialized in the area of high-precision ball bearings as well as the production of high-performance and long-lived deep groove and spindle ball bearings to meet – or even exceed – the highest precision classes P4 and ABEC 7. Certification under international standards ensures the highest precision in the development and manufacturing of GMN ball bearings and guarantees constant, outstanding qualities related to speed suitability, stability and longevity. The broad product range includes a large selection of standard solutions as well as requirements-tailored special designs.

Request for a quote

XIMEA GMBH

Germany

cccThis scientific camera line provides super sensitive, linear, and accurate data for your precise measurements. Its sCMOS sensors deliver CCD image quality with CMOS speed over a USB3 interface with Type-C connection and power delivery protocol. The compact housings come with Peltier cooling for sensor temperatures down to -25 °C. Photon starved applications will love the simplicity of getting a cooled camera up and running with little fuss. Imaging the very large (astronomy) to the very small (microscopy), our scientific cameras have you covered. Reaching a resolution of 15.1 Mpix (5,056 x 2,968 pixels) and up to 17 fps pixels.

Request for a quote

KULLEN-KOTI GMBH

Germany

The types 220 & 221 are extremly flexible in their dimension and depending on the required performance these endless spiral brush coils are mounted on core systems made of mild steel, stainless steel or non ferrous metals.Compared with other brush designs we can reach the highest possible fill density with these types and they can be applied with a maximum speed of 55 m/sec without any problems. Supposition for it, is that the roller brush cores are electrodynamically balanced after the mounting of the core according to the required rotation speed and quality G 2.5 which comes up to ISO 1940. Our roller brushes are supplied with a fill surface perfectly trimmed and/or ground for concentricity. A perfectly seated attachment of the coils on the roller core is guaranteed by the pressure or mounting ring (PRB) system, also available with removable balancing weights (PRB-AW), which prevents the brush coil from rotating on the core. In some circumstances you also could choose a...

Request for a quote

MATTHEWS MARKING SYSTEMS GERMANY GMBH

Germany

Our Drop-on-Demand (DOD) systems feature the longest life and most reliable printhead in the industry. The exclusive micro-valve technology dramatically lowers ink consumption while maintaining impressive quality and speed. Our robust 8000+ series printheads produce a high-resolution mark by overlapping a series of smaller dots.

Request for a quote

CPC EUROPA GMBH

Germany

Low-noise, high-quality and high-speed ball chain (patented). The WRC ball chain (patented) design offers high contact area between the balls and the chain, which helps keep the lubricant film intact, hence allowing high-speed and low-noise operations with extended service life. — Dustproof design: The completely sealed design helps prevent dust ingress and reduce lubricant loss, which leads to extended service life. — O-type arrangement: The 4-row re-circulating balls design helps achieve equal load capacity in all four directions. — Patented design for high speed/impact: The L-shaped stainless-steel reinforcement plates with bottom latches help cover and strengthen the end caps, allowing high-speed/impact operations.

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

Due to its revolution speed and high performance this quality machine can be used diversely, e.g. with a collet for tools of 3–8 mm diameter. A very impressive machine that stands for endurance and strength whilst meeting all ergonomic and weight requirements. A version with a pair of supports for hard applications is also available.

Request for a quote

RUHLAMAT GMBH

Germany

Get a higher level of automation and increased efficiency, without compromising quality and precision. Our affordable and proven solutions, ranging from encapsulation, testing and encoding of chip modules to glue tape lamination, provide the speed, quality and economy for profitable chip module production. RFID Inlay Production Wire embedded antennas produced on ruhlamat machines are extremely cheap and yet provide the best product characteristics compared to etched or plated antennas. Our reliable machine solutions offer great flexibility and productivity, enabling you to make both prototypes and mass products in an economical way and with consistently high quality. From antenna embedding to production of complete RFID inlays and eCovers, the options are versatile. Card Personalisation We excel in providing innovative card personalisation solutions. Our system enables you to produce highly personalised smart cards, secure IDs, and financial cards quickly and economically. We...

Request for a quote

RUHLAMAT GMBH

Germany

The WCE2000 is our fastest and most productive high-volume system for wire embedding and RFID inlay production. You get unrivalled real-world throughput with up to 4,050 antennas per hour as antenna embedding machine and up to 2,000 finished RFID inlays per hour as inlay manufacturing line. This modular and flexible system allows processing of various substrates and provides sheet to sheet (S2S), reel to sheet (R2S), or reel to reel (R2R) handling. WCE700 - Semi-Automatic Production System The very economical WCE700 can handle both small jobs and high-volume runs easily with up to 1,600 inlay sheets per hour. The system is capable to work with a wide range of substrates and can also be used for only antenna embedding, with unrivalled speed, accuracy and the quality of antennas that it produces. WCE150 - Laboratory System You are looking for a convenient solution for laboratory usage to produce prototypes or low-volume jobs? The affordably priced WCE150 is designed to produce...

Request for a quote

RUHLAMAT GMBH

Germany

The WCE700 is a semi-automatic system designed to produce RFID inlays for ID documents (ID-1 and ID-3 format). Based on a 4-station roundtable concept with manual load and unload, this very economical solution can handle both small jobs and high-volume runs with ease. Depending on the configuration, it can produce up to 1,600 inlay sheets/hour. The machine can also be used solely for antenna embedding, with unrivalled speed, accuracy and the quality of antennas that it produces. This modular system is equipped with ultrasonic wire embedding, automatic chip module punching and module placement at defined positions on the table. The electrical connection between antenna and module is accomplished either by thermo-compression bonding or soldering method. The operator will feed and take out the inlay sheet manually. The WCE700 is capable to work with a wide range of materials, and variables like the size and shape of the antenna can easily be adapted to the specific requirements. Our...

Request for a quote

RUHLAMAT GMBH

Germany

The WCE150 is designed to produce RFID inlays for ID documents in the ID-1 and ID-3 format. Based on a single-station concept with manual load and unload, it is a convenient solution for laboratory usage to produce prototypes or low-volume jobs with up to 40 inlay sheets/hour. The machine can also be used solely for antenna embedding with unrivalled speed, highest accuracy, and unbeaten quality of antennas that it produces. Chip module punching and placement, antenna laying by ultrasonic wire embedding technology, and thermo-compression welding or soldering are the main features to be combined for a customised solution. The operator will feed and take out the inlay sheet manually. The sheet will be fixed on the table by vacuum. This guarantees a safe and clean processing. The system is capable to work with a wide range of materials, and variables like the size and shape of the antenna can easily be adapted to the specific requirements. Our excellent sonotrode expertise for...

Request for a quote

RUHLAMAT GMBH

Germany

Encapsulation is the method for protecting the chip and wires against mechanical stress and environmental influences. For this purpose, cast resin is dispensed and then cured by UV light or heat, depending on the type of resin. The PowerSeal offers highest quality and maximum speed for the encapsulation of chip modules with up to 40,000 modules/hour. PowerTest - Chip Module Test System The inspection of IC modules for smart cards and RFID devices, based on parametric and functional testing, is an integral part in the production flow and quality assurance. The PowerTest is designed for high-speed testing and encoding of chip modules on 35 mm tapes. The system is also perfectly suited for initialisation and personalisation of IC modules, including OS loading. GTL700 - Glue Tape Lamination System The GTL700 is a highly reliable and flexible system for glue tape lamination of chip module tapes in preparation for the hot melt implanting process. The very efficient system can...

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

The AirWave2 is the latest development resulting from thousands of installed and tested AirWave1 air cushion machines from FLOETER Fast air cushion production (type 7 AirWave filler and type 8 wrapper films) up to 20 m/min Program memory for 5 film types Interactive touch display High-tech sealing unit Quick start-up in under 1 minute Low maintenance Compatible with AirWave1 Sensor and other accessories (available seperately). Weight: about 6,5kg Uncompromising on efficiency, speed and quality, the AirWave2 is the most flexible and user-friendly premium Model of our AirWave series. Low maintenance, quiet, durable – made in Germany. Chain production:Yes (AirWave type 7) Quilt production:Yes (AirWave type 8) AirWave films:Bio, ECO, ESD, Heavy Duty, Standard, Super ECO Output m/min:to 20 Meter/roll (m):to 3000 Film thickness (μm):12 - 30 Roll formats stock:94 Length (mm):413 Width (mm):316 Height (mm):232 Weight (kg):6,5

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

High Speed Compact Modular Mounter JUKI’s RX 6 is the perfect solution for companies in need of a wide variety of components and large printed circuit boards as well as having to depend on quick product changes while maintaining high quality. The high speed compact modular mounter is suitable both for small and large volumes. Due to the compact design of the machine featuring a width of only 1.25 metre the RX 6 displays a smart solution in the case of production floor space being an expense factor.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELTEX-ELEKTROSTATIK-GMBH

Germany

Electrostatics disturb almost all production processes. Eltex systems prevent uncontrolled discharges and integrate electrostatics precisely into your processes. In our product portfolio for cleaning with ionized air you will discover systems and products for many industrial sectors. Ion blower technology is characterized by much higher ionization power and a larger ionization range. Ion blower pistols shine in manual applications with a fixed installation of the ion blower nozzles and ion blower nozzle carriers. The compact design and high efficiency enable a wide range of applications. Electrostatic charges occurring during production processes often cause severe disruptions, reducing production speed and product quality. The R55 ion blower head and the PR55 ion blower pistol are both components of the newly developed discharging system with ultimate depth effect; the blower head for fixed installation and the blower pistol for manual and mobile use.

Request for a quote

PARTEX MARKING SYSTEMS GMBH

Germany

Moca is a compact and powerful card printer. It has fast print speed and excellent print quality. Print Thermal transfer printing: 300 dpi print resolution Printing speed: 500 cards/hour monochrome Temperature range Operating temperature: +15ºC to +30ºC Storage temperature: -5ºC to +55ºC Operating humidity: 20% to 65% non-condensing Storage humidity: 20% to 70% non-condensing To obtain the best printing result, the temperature of the profile shouldn’t be lower then +20ºC. Measurement 395x200x250 (LxWxH

Request for a quote

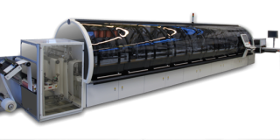

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Compacting is the last finishing process after relaxation or drying and has thus decisive importance for the residual shrinking, the hand and the aspect and the shine of the fabric before cutting and makeup. The BRÜCKNER compacting calender is characterized by an extremely short fabric path, an optimum traction control and a sophisticated drive technology allowing high production speeds with consistent fabric quality. Depending on the fabric type and the quality requirements, BRÜCKNER can offer the following compacting solutions two felt belt compactors arranged one behind the other, rubber belt shrinking unit according to the Sanfor principle, rubber belt shrinking unit with downstream arranged felt belt compacting calender. In addition, the following units can be integrated into the compacting line equalizing frame for the overspreading and width control, straightener, steamer unit, edge cutter (knife or scissor type).

Request for a quote

MÜLLER CO-AX GMBH

Germany

The technology in the FMX series stands for higher flow rates compared to other valves. Or are you looking for compactness? Our FMX valves occupy just a small installation space, while offering the same speed and quality.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

With just a few settings the plasma cutting units of the Smart Focus series achieve excellent results in the cutting range from 1 to 100 mm. Even under challenging conditions highest cutting quality and speed are realised. Therefore we use our proven cutting technologies as for example Contour Cut for cutting mild steel. The optimised gas control units and torches protect the consumables, reduce the gas consumption and the costs per cutting metre.

Request for a quote

COGNEX CORPORATION

Germany

Cognex barcode verification technology ensures the readability and compliance of 1D and 2D barcodes to industry standardization guidelines. Today most companies spot check codes one at a time using an offline, operator-based verifier which can be slow and cumbersome. The DataMan 475V series inline barcode verifier provides automated high-speed verification and quality reporting directly on your line to prevent product waste and chargebacks. Immediate feedback and visual diagnostic information provides operators with the ability to identify and correct printing and process control issues as they happen. Detailed reports can be generated for traceability, process control, and compliance.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy-to-use chamfering machine was designed for the deburring and chamfering of small to medium-sized workpieces and bar material starting with a thickness of 1 mm. The machine generates a very good chamfering quality thanks to the optimized interaction between the cutter head and cutting inserts. In NE metals and steel, a chamfer width up to 11mm is possible. The WKF 170 has gradual speed regulation, which is very useful when processing aluminum or stainless steel. The angle adjustment can cover a range from 15-60° in 5° steps. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machine can be installed on an undercarriage for flexible use in a workshop, which simultaneously serves as a chip box. The machine can be extended with roller guide ways or converted into an automatic chamfering machine.

Request for a quote

ASSFALG GMBH

Germany

The KSM 125 and KSM 130 edge grinding machines are designed for deburring and edge cutting of small to big workpieces starting with a thickness of 2 mm. The chamfer is scrubbed and finished in one step with our two-zone grinding disc. The chamfer setting is made by opening / closing the prism. This is used effectively and efficiently through the axial adjustable corundum grinding disc. The KSM 125 has an integrated extraction socket for connection to an extraction system. A water cooler is installed in the KSM 130. The machines are equipped with hardened and polished guide rails. Hardened workpieces and HSS materials can be processed p to 5mmx45° in multiple steps. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machines can be installed on an undercarriage for flexible use in a workshop.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy chamfering machine is designed for deburring and chamfering of small to large workpieces from 1 mm thickness. The machine generates a perfect chamfering quality thanks to the optimized interaction between the cutter head and cutting inserts - like sanded. In NE metals and steel, a chamfer width up to 10mm is possible. The ASO160-M is ideal for processing steel and aluminum. The ASO 160-MSL design has speed regulation that is very useful for the processing of aluminum or stainless steel. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machine can be installed on an undercarriage for flexible use in a workshop, which simultaneously serves as a chip box.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy chamfering machine is designed for deburring and chamfering of small to large workpieces from 5 mm thickness. The hardened and sanded guide rails must be turned for smaller and thinner workpieces starting with a thickness of 2 mm. Thanks to the optimised interplay of cutter head and cutting inserts, the machine ensures clean and constant chamfering. A chamfer width of up to 12 mm is possible in NE metals and a chamfer width of up to 10mm in steel. The cutting edge length of the cutting inserts can be used 100% thanks to the innovative axially adjustable motor shaft. The ASO 650-WSL has speed regulation that is very useful when processing aluminum or stainless steel and a gradual angle adjustment in a range from 15-45°. A radius processing from R1.2 to R6 is possible with different cutting inserts. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy chamfering machine is designed for deburring and chamfering of small to large workpieces from 2 mm thickness. The sturdy cast iron casing, the hardened and sanded guide rails, the speed regulation and the integrated chip box convince in every regard. Thanks to the optimised interplay of cutter head and cutting inserts, the machine ensures clatter-free, clean and constant chamfering. A chamfer width of up to 10 mm is possible in NE metals and a chamfer width of up to 5mm in steel. Hardened workpieces, HSS and hard metal materials can be processed through optional CBN and diamond grinding discs. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machine can be installed on an undercarriage for flexible use in a workshop.

Request for a quoteResults for

Speed quality - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Industrial cutting machine tools (5)

- Adjustment - machine tools (1)

- Bar code technology (1)

- Cameras, cinematographic (1)

- Conveyor belts (1)

- Electronic components (1)

- Engines & Parts (1)

- Furnishings, cushioned (1)

- Labelling machines (1)

- Marking - diverse products (1)

- Mechanical transmission - components (1)

- Moulding, rubber - machinery (1)

- Paper - Printing - Machines & Equipment (1)

- Plasma cutting machines (1)

- Printers - computer (1)

- Sensors (1)

- Valves for industrial fittings (1)