- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- slide plates

Results for

Slide plates - Import export

FEDERAL-MOGUL DEVA GMBH

Germany

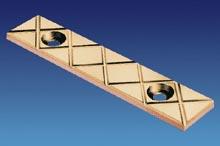

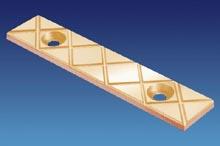

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

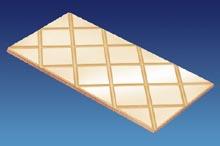

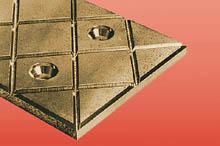

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FÖHRENBACH GMBH

Germany

This guiding system makes it possible to accurately position your products. Furthermore, you can fix it exactly at the desired place. The innovation lies in the backlash-free clamping, horizontal and vertical side misalignment ≤ 3 μm. Useful advantages: compact sizes and the possibility of adjusting and locking the guide by a hex screwdriver. Clamps permit a fast combination to 2 axis systems and/or 3 axis systems or the fitting of axis systems on a base plate. Features Dovetail slides made of Aluminium, natural anodized 5 sizes: 20, 30, 50, 80, 120 mm with standard stroke between 5 and 100 mm Backlash-free clamping Compact sizes Adjustment with knurled micrometer knob (standard) or hex screwdriver High load ratings Guides without play High damping Scale with knurled micrometer knob Mounting kit (clamps) Easy and quick to combine to 2 axis systems and/or 3 axis systems Optional position readout (starting from size 30 mm)

Request for a quote

FÖHRENBACH GMBH

Germany

This guiding system makes it possible to accurately position your products. Furthermore, you can fix it exactly at the desired place. The innovation lies in the backlash-free clamping, horizontal and vertical side misalignment ≤ 3 μm. Useful advantages: compact sizes and the possibility of adjusting and locking the guide by a hex screwdriver. Clamps permit a fast combination to 2 axis systems and/or 3 axis systems or the fitting of axis systems on a base plate. Features Dovetail slides made of Aluminium, natural anodized 5 sizes: 20, 30, 50, 80, 120 mm with standard stroke between 5 and 100 mm Backlash-free clamping Compact sizes Adjustment with knurled micrometer knob (standard) or hex screwdriver High load ratings Guides without play High damping Scale with knurled micrometer knob Mounting kit (clamps) Easy and quick to combine to 2 axis systems and/or 3 axis systems Optional position readout (starting from size 30 mm)

Request for a quote

FÖHRENBACH GMBH

Germany

This guiding system makes it possible to accurately position your products. Furthermore, you can fix it exactly at the desired place. The innovation lies in the backlash-free clamping, horizontal and vertical side misalignment ≤ 3 μm. Useful advantages: compact sizes and the possibility of adjusting and locking the guide by a hex screwdriver. Clamps permit a fast combination to 2 axis systems and/or 3 axis systems or the fitting of axis systems on a base plate. Features Dovetail slides made of Aluminium, natural anodized 5 sizes: 20, 30, 50, 80, 120 mm with standard stroke between 5 and 100 mm Backlash-free clamping Compact sizes Adjustment with knurled micrometer knob (standard) or hex screwdriver High load ratings Guides without play High damping Scale with knurled micrometer knob Mounting kit (clamps) Easy and quick to combine to 2 axis systems and/or 3 axis systems Optional position readout (starting from size 30 mm)

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 1992 1 drilling head table model for hand operation slide plate manual handle Delivery time: immediately Ref: ST200187A Please ask for price. We ship and install worldwide!

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 2000 table model 2 drilling heads electr. drive manual handle slide plate Delivery time: immediately from stock Ref: NA200211A Please ask for price. We ship and install worldwide!

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

MACK current collector trolleys are used in moving current consumers, such as cranes, suspended rail systems, or high rack vehicle systems. What are you considering? Where can we offer you support in system development? Our current collector trolleys, complete with carbon brushes and fittings, are guided by sliding plates or castors with bearings in contact-protected linear conductor lines. Our customers around the world include leading system suppliers who order customer-tailored current collector trolleys from MACK, ready to install from a single source. Of course, we can also produce any special type that you require, for example fast-running versions or double-current collector trolleys.

Request for a quote

BIZLINK ROBOTIC SOLUTIONS GERMANY GMBH

Germany

With LSH Delta we offer an additional product – next to our premium dresspack, the LSH 3. The LSH Delta‘s benefits include: -> Cutting-edge development: A state-of-the-art retract system designed to smoothly and reliably run your operations. -> Seamless integration: The The LSH Delta seamlessly integrates with many robot brands like FANUC, ABB and KUKA. -> User-friendly design: Enjoy the convenience of tool-free and quick opening and closure of the retract system housing, streamlining your maintenance and operational processes. Dresspack maintenance has never been so easy. -> Adjustable flexibility: The LSH Delta’s retract system can be easily adjusted on its base plate using Slide & Click technology – offering you reduced installation time and options to fine-tune in the field. -> Versatility in your spring choice: Different spring forces available. Featherweight system: Crafted with advanced, strong polymer-based material, the LSH Delta is incredibly lightweight at just 4.1 kg.

BETONBAU GMBH UND CO. KG

Germany

Our ventilation systems ensure that an optimum air exchange is achieved within technical buildings (e.g. for cooling transformer and low voltage rooms) and prevent penetration by snow, rain and insects. Individual elements can be flexibly adapted to suit building conditions and are suitable for integration in both doors and walls. Designs: Standard surface: anodised aluminium E6 EV 1 silver Production in recommended sizes or to suit building conditions With a horizontal perforated sheet (for LLE) With integrated swirl chamber for use in conditions involving driving snow and high wind speeds (for LSU/LSO) Aerating coupling for continuous venting Ventilation domes Miniature ventilators Slide ventilators Options: Anodised, painted or powder-coated surface – choice of colours Slide plate for manual air flow control Ventilator units for forced ventilation and aeration All-round swirl frame Special version for Type LLE: break-in inhibiting WK3 conforming to DIN ENV 1627 Our DRO and...

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

Rotary arm with ceiling fixture Fixture of the rotary arm at the ceiling. Rotary arm with wall fixture Fixture of the rotary arm at the wall or existing column. Column mounted slewing crane Column mounted slewing crane for the AERO-LIFT tube lifter. The slewing area is 270° an the arms are in different dimensions available. Folding arm Ceiling rail system Aluminium easy sliding rail system. Mobile base plate This flexible solution with the mobile bottom plate allows to use the tube lifter for some workplaces. The mobile column mounted slewing crane can be moved with a forklift or with wheels. A fixtation at the floor is not necessary. Special solutions Customized special solution for tube lifters

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure with integrated dove tailed slideway for the workhead and steady rest. The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled drawer type coolant reservoir which can be drawn out for ease of cleaning. The machine base houses also the control panel for the motors. Grinding Spindle The permanently sealed and lubricated grinding spindle slides on a swivel plate which is provided with an integrated dove tailed slideway. The swivel plate is set to the desired valve angle by means of a wide spaced scale. Steady Rest An unique selfcentering steady rest is provided for additional support of long stem valves. Both the workhead and the stready rest are adjustable along the slideway on the machine base to clamp the valve on that part of the valve stem which normally travels in the valve guide.

Request for a quote

ACHBERG SILOANLAGEN GMBH & CO. KG

Germany

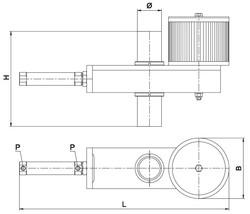

- material (pipe connection): stainless steel - material (valve housing): aluminium - material (slide plate / via hole): PET / stainless steel - compressed air supply: 1/8"; 6 bar; oil-free and dry - power supply: 24 V DC The pneumatic fittings and the magnetic valve are complete assembled. One pneumatic adapter (6 and 8 mm) is enclosed. The via hole is power-off open. Ø P B L H AS.20.040.F.024V 40 1/8" 74 414 196 AS.20.045.F.024V 44.5 1/8" 84 440 232 AS.20.050.F.024V 50 1/8" 84 440 196 AS.20.060.F.024V 60.3 1/8" 94 456 206 AS.20.076.F.024V 76.1 1/8" 118 545 257

Request for a quote

ACHBERG SILOANLAGEN GMBH & CO. KG

Germany

- material (pipe connection): stainless steel - material (valve housing): aluminium - material (slide plate): PET - compressed air supply: 1/8"; 6 bar; oil-free and dry - power supply: 24 V DC The pneumatic fittings and the magnetic valve are complete assembled. One pneumatic adapter (6 and 8 mm) is enclosed. The valve is power-off closed. Ø P B L H AS.10.040.01.024V 40 1/8" 74 310 170 AS.10.045.01.024V 44.5 1/8" 84 360 208 AS.10.050.01.024V 50 1/8" 84 360 172 AS.10.060.01.024V 60.3 1/8" 94 400 172 AS.10.065.01.024V 65 1/8" 114 488 294 AS.10.070.01.024V 70 1/8" 114 488 266 AS.10.076.01.024V 76.1 1/8" 114 488 224 AS.10.080.01.024V 80 1/8" 128 564 283 AS.10.084.01.024V 84 1/8" 128 564 260 AS.10.089.01.024V 88.9 1/8" 128 564 224

Request for a quoteResults for

Slide plates - Import exportNumber of results

21 ProductsCountries

Company type