- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sizes to measure

Results for

Sizes to measure - Import export

QUELLTECH GMBH

Germany

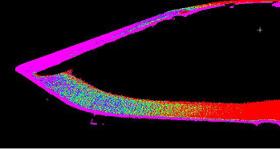

Particular Challenges: The seal surfaces in this case are made of very glossy metal, with the drawback of emitted reflections. This effect during an optical measurement must be eliminated. Furthermore, it is absolutely necessary to guide the laser scanner on a linear path over the surface, since fluctuations of distance may falsify the measurement result. QuellTech Solution: The Quelltech model Q5 disposes of an adequate resolution in X and Z direction and proves to be able to verify the planarity tolerances and to measure the size of defects. Meanwhile a precise rotary axle, used as guiding element, moves the scanner over the surface to be evaluated. Interfering artefacts caused by the glossy finish are suppressed by particular algorithms integrated within the software. As an encoder value is permanently supplied by the rotary axle, the position of each scanner profile within the point cloud can accurately be determined.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Thanks to latest digital technoloy, we can meet your demands at a high professional level. We provide 2D/3D measurement (e.g. dimension measurements, burr measurements, grain size analysis, residual contamination analysis according to ISO 16232 & VDA 19, profile measurements, particle analysis, 3D presentation) with multi-lightning view for various illumination angles, optical shadow effects to clearly identify smallest univenness, reflexion reduction and HDR-view for high colour graduation. Several types of perspectives are possible thanks to a pivoted angle of sight (up to 90°) or by adjusting the mobile object lense (e.g. hollow spaces). We compile a detailed documentation including pictures or videos, where even real-time swivellling views can be recorded. We are looking forward to receiving your enquiry!

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This transducer can be used anywhere thanks to its small size. Designed to work without a measuring chamber (uses a flush front diaphragm instead), this transducer is ideal for any measurements where the material to be measured may leave problematic residues. The range of suitable applications is even greater thanks to a choice of screw-on or weld-on adapters. Areas of use: Bottling plants, food industry Mixing facilities for the chemicals industry Pharmaceuticals Cosmetics industry Bioengineering These miniature pressure transducers are made entirely of titanium and therefore have outstanding resistance to corrosion. These convert the pressure-induced deflection of the diaphragm into a change in electrical resistance, which can be amplified, measured and processed by external electronic circuitry.

Request for a quote

SUVIS GMBH

Germany

Particle size measurements are important in various applied sciences and in engineering, for example in fuel burning or in cavitation research as well as in particle size control. In all these applications it necessary to have knowledge about the particle dynamics. To gain that knowledge one has to measure the particle size and its velocity if possible in a noninvasive way with high local and temporal resolutions. A device which makes such measurements possible is the so called PhaseDopplerAnemometer (PDA), which has several advantages. First, it exhibits a large dynamic range from micrometer particles up to sizes in the millimetre range. Then it is very precise and no calibration procedure is necessary. Moreover, it is very robust against optical distortions. In the following the working principle of this flow and particle measurement technique will be explained.

Request for a quote

SUVIS GMBH

Germany

For the generation and production of a spray the knowledge of information like the desired droplet size and its distribution is of fundamental importance. In order to characterise a spray correctly, one has to know the droplet size distribution of the droplets, which were generated out of a given liquid. In many applications it is desired to produce very small droplets. For the design and lay out of inhalers for example, it is necessary to achieve droplet sizes not larger than approximately 10 μm to be absorbed by the lungs. When one designs an atomisation nozzle in view of the desired droplet size distribution, one has to make sure via measurements, that the nozzle is really able the produce the expected droplet size distribution within an acceptable uncertainty range. Besides the droplet size distribution, the droplet velocity is an important parameter since it is a measure of the droplet momentum.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Sizes to measure - Import exportNumber of results

5 ProductsCountries

Company type