- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sintered metals

Results for

Sintered metals - Import export

BORNEMANN GMBH

Germany

Machine dies made from sinter metal that achieve a hardness of 68 to 70 HRC are a speciality of ours. With these dies, materials with a surface hardness of up to 48 HRC can be labelled. By using a complex production method and a special hardening, special options of use in labelling are achieved for these unique hard dies. The dies are produced to customer drawing or data.

Request for a quote

BORNEMANN GMBH

Germany

For hard castings, we offer manual dies made from sinter metal. Sinter metal dies are characterised by a hardness of 68 to 70 HRC. With these dies, welded or processes hard surfaces can be labelled. Company logos as well as individual numbers and letters can be provided. The maximum font size should not exceed 10 mm.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase performance of your pneumatic systems Powering pneumatic machines requires clean and conditioned air or gas. Our pneumatic filters are designed to work together with regulators and lubricators (FRL units), to offer outstanding performance and a lower-cost alternative to traditional sintered-metal filters. Specifically designed to provide an excellent combination of particulate filtration, air flow and back pressure performance, while complying with strength and aesthetic requirements, these single-component molded filters: Meet your filtration requirements – Optimized design meets filtration, airflow and pressure drop requirements. Reduce costs – Sintered polymer filters are more cost-effective than sintered metal. Improve machine longevity – Design is optimized for reliability, efficiency and longevity of pneumatic machinery. Features Work together with regulators and lubricators (FRL units) to deliver clean and conditioned compressed air or gas Strong and rigid for...

Request for a quoteFAUDI GMBH

Germany

Advantages Each filter element is individual back blown for a good cleaning effet Area of application Self-cleaning filter for the filtration of gases Flow rate Various filter sizes and the modular design enable any required flow rate. classification number F35 Filter aid - Filtration degree 0,5 - 10 µm Medium Nitrogene, gases Filter material Sinter-metal Cartridges, CrNi-Steel Cartridges

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For sliding properties improvement of machine parts, apparates and precision machinery, especially for microfinished surfaces For incorporation in plastics, sealings, packages, sintered metals and improvement of sliding properties For long-term or possibly lifetime-lubrication Advantages and benefits Reduces friction and wear in a wide temperature range High effectiveness due to high affinity of MoS₂ to metals Low friction at highest load capacities Low consumption based on forming of extreme thin sliding films Not electrically conducting and not magnetic Chemically stable except against halogenated gases, concentrated sulphuric- and nitric acid For best adhesion, clean sliding surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Spray on evenly thin from 15-20 cm distance to the sliding surfaces.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For sliding properties improvement of machine parts, apparates and precision machinery, especially for microfinished surfaces For incorporation in plastics, sealings, packages, sintered metals and improvement of sliding properties For long-term or possibly lifetime-lubrication Advantages and benefits Reduces friction and wear in a wide temperature range High effectiveness due to high affinity of MoS₂ to metals Low friction at highest load capacities Low consumption based on forming of extreme thin sliding films Not electrically conducting and not magnetic Chemically stable except against halogenated gases, concentrated sulphuric- and nitric acidFor best adhesion, clean sliding surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply on small parts in series production by tumbling, under addition of small amounts powder and tumbling parts, until a complete MoS₂ film is formed. Brush the powder onto bigger surfaces.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For sliding properties improvement of machine parts, apparates and precision machinery, e.g. under the influence of oxygen, in vacuum or radioactive radiation Dry lubrication for tools or workpieces in cold- and thermoforming For incorporation in plastics, sealings, packages, sintered metals and improvement of sliding properties For long-term or possibly lifetime-lubrication Advantages and benefits Reduces friction and wear in a wide temperature range High effectiveness due to high affinity of MoS₂ to metals Low friction at highest load capacities Low consumption based on forming of extreme thin sliding films Not electrically conducting and not magnetic Chemically stable except against halogenated gases, concentrated sulfuric- and nitric acidFor best adhesion, clean sliding surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply on small parts in series production by tumbling, under addition of small amounts powder and tumbling

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Potentiometric position transducer with very compact dimensions; robust design with metal flanges; sintered bronze plain bearing; long life span and high adjustement speed; easy to assemble via sliding metal mounting clamps; High protection class

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Potentiometric position transducer with very compact dimensions; robust design with metal flanges; sintered bronze plain bearing; long life span and high adjustement speed; easy to assemble via low-backlash pivot heads with a large angle of freedom; High protection class

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

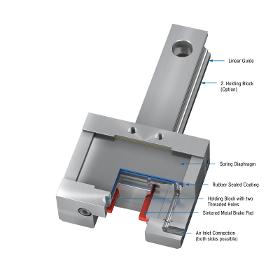

Safety Clamping for Rail Systems, Compact Holding force 300 N Small can clamp perfectly too: The LOCKED-Family SLK clamping elements are more compact than the Series SL. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and safe. Thanks to the patented spring steel plate system, the product family SLK achieves clamping and holding forces of up to 2,100 N with the shortest reaction times when vented. Thanks to the sintered metal coatings and the clamping function in emergency stop (e.g. in case of a power failure), this range enables braking directly on the rail. All clamping elements offer the maximum holding and braking forces and achieve up to 1 million clamping cycles or up to a maximum of 500 emergency braking operations in the 4 and 6 bar version.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

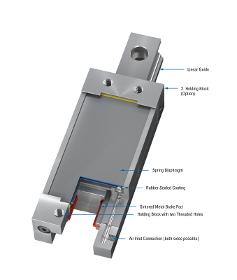

Safety Clamping for Rail Systems Holding force 540 N Always on the safe side: The safety clamping elements LOCKED SL clamp and brake directly on the clear area of guide rails on linear modules with forces of up to 10,000 N. They are individually adjusted to the linear guide being used and are available for all rail sizes from 20 to 65 mm and profiles from all renowned manufacturers. Special brake pads made of low wear sintered metal are used for the additional emergency stop braking functions in the safety clamping elements LOCKED SL. The SL product family offers optimum static clamping with a service life up to 1 million cycles or up to 500 emergency braking operations. They also offer low system costs in comparison with hydraulic and electric solutions.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The AccuCarb® Ceramic Probe is a high accuracy zirconia oxygen sensor designed for the heat treating industry. AccuCarb® Ceramic Probe is a patented, ceramic sheathed probe, high temperature probe, specifically designed for generator and for metal sintering applications. The standard model has an integral type K thermocouple and a tube fitting for air purge burnout of soot.

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Component for Filter Dryers The multilayer filter plates are supplied according to material requirements and permeability: Fabric (cotton, polypropylene, etc.) Filter elements made from metal Sintered plates Multi-layered plates, sintered Sterile configuration, filter elements are secured from below The existing filter plates for filter dryers can be replaced smoothly and quickly anywhere. This is also possible for machines from other suppliers. According to the customer´s requirement and machine specification the replacement of multilayer filter plates is done completely or separated in different sectors. Multilayers are available in SS 316L or Hastelloy C22 or other materials on request, available porosities 5, 10, 20 or 40 micron, other porosities on request. For machines with a bigger diameter – mainly for chemical specification – the division in different sectors offers, in case of break, the advantage that only the damaged part has to be replaced. This guarantees an...

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

COD Sinter-HIP furnaces combine the dewaxing, vacuum-sintering and subsequent isostatic densification under pressure gas up to 100 bar of sinter parts made of hard metals or ceramics. COD furnaces optimize all the necessary process functions and combine them in one production equipment and process cycle in an optimal, fully automatic and reproducible manner. Applications: Vacuum- and pressure sintering of hard metal products, PM-high-speed steels and ceramics. Benefit for users: • Low operating costs due to low power and cooling water consumption • High product quality due to excellent temperature homogeneity in vacuum, during pressure gas injection and pressure sintering. • Rapid startup at user's site and productivity "from day one" due to complete pre-assembly and fully hot shop-test and TÜV-acceptance in the factory • Service and maintenance friendly design, high up-time

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

OV heat treatment furnaces are high performance most efficient furnaces with a wide working-temperature and application range. Due to the compatibility with all kind of process gases and the fully automatic process runs they are especially suitable for the economic application in industrial productions for example to produce hard metals or the cleaning and purification of graphite. Applications: • operating temperatures up to 1.100 °C: heat treatment, brazing, reduction, degassing and debinding • operating temperatures up to 1.350 °C: heat treatment, brazing, degassing, debinding and sintering • operating temperatures up to 1.600 °C: debinding and sintering of hard metals • operating temperatures up to 1.800 °C: sintering of non-oxydic ceramics • operating temperatures up to 2.000°C: CVD- and pyrolytic processes, degassing, cleaning, sintering • operating temperatures up to 2.400 °C: CVD-processes, degassing, cleaning • operating temperatures above 2.

Request for a quote

NIPPON KORNMEYER CARBON GROUP GMBH

Germany

NKCG offers a complete portfolio of carbon-based products for vacuum sintering process of hard metals and ceramics.

Request for a quote

FERNSTEUERGERÄTE KURT OELSCH GMBH

Germany

For measuring linear displacements on machines and converting them into electrical signals for teletransmission purposes - linear displacement transmitters of the potentiometric, inductive, incrementally or absolutely coded type can be used, depending on their application. Potentiometric linear displacement transmitters comprise high-resolution wirewound resistance elements, capable of measuring length up to 1 m with high accuracy and a linearity of ± 0,1%. For protection against mechanical damage, plunger with sintered metal bearing and pull-back spring (optional) are encapsulated in a robust aluminum casing, degree of protection IP 65. Inductive linear displacement transmitters comprise a non-contact differential inductor system providing high linearity and resolution, capable to perform reliable measuring ranges from 0 to 0.5 mm up to 0 to 500 mm even under extremely severe environmental conditions.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Sintered metals - Import exportNumber of results

17 ProductsCountries

Company type