- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sheet manufacturer

Results for

Sheet manufacturer - Import export

GEBR. DÜRRBECK KUNSTSTOFFE GMBH

Germany

Why make something complicated when you can make it easy? PE sheets – made to order in the size you need – save you the time and effort of manually or mechanically cutting plastic covers. PE sheets are pre-cut flat film sheets. PE sheets from Dürrbeck are manufactured bespoke to meet your needs. Plastic sheets are used as covers for pallets, as a liner between individual packaged units, or as a packaging material itself. When combined with stretch film pallet wrap, it provides excellent protection against dirt, dust and the elements. Our custom-made PE sheets also act as a simple liner or cover for goods in a warehouse or in transport. We produce plastic sheets loose or perforated on rolls – simply tear off, use, done! Dürrbeck plastic sheets are a favourite among customers because of their high quality, convenience and unbeatable value for money.

Request for a quote

NEWOS GMBH

Germany

INTRODUCING NEWOLAN® NEWOLAN®- rheology additives – Products that make coating easier Many important plastics accrue during manufacture as fine particulate powders. It is often difficult to produce sheeting from them on a supporting material for example for floor coverings. Therefore, before mechanical shaping as a surface can occur, these powders must first be converted into a flowable or spreadable paste with a fluid medium. Such pastes are called plastisols. In the process, rheology additives optimally adapt the flow behavior (rheology) of the PVC pastes to the process parameters during sheeting manufacture. Under the brand name NEWOLAN®, NEWOS offers innovative and market-tested rheology additives that can be optimized to your requirements at any time.

Request for a quote

METAWELL GMBH

Germany

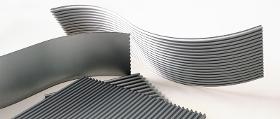

lightweight aluminium panel, where a cover sheet is connected to a corrugated aluminium sheet in a continuous manufacturing process material with highly anisotropic stiffness, resulting in a very simple two-dimensional shaping is possible (see video) simple processing of the material with standard tools high corrosion protection since all used aluminium sheets are pretreated with a primer 100 % recyclable without prior separation of materials. In addition, the proportion of secondary aluminum is approximately 90 %. Easiest forming with Metawell Aluflex Navigation Metawell Aluflex Easiest forming with Metawell Aluflex Design and delivery program Forming parallel to the corrugation Forming vertically to the corrugation Powder-coatable material Video of forming Metawell Aluflex Metawell Aluflex is a material with rigidity levels that depend strongly on the direction. The corrugated sheet is bonded to only one aluminium cover sheet. This structure enables easy 2D-forming and...

Request for a quote

TEPROSA GMBH

Germany

Baking varnish is a special joining technology for sheet metal packages. After the individual lamellas have been cut, electrical steel with a baking varnish coating is baked into a sheet metal package in a two-stage temperature step. The result is a full-surface, solid connection between the individual sheets with complete insulation. Sheet metal packages manufactured in this way have high precision and perfect magnetic properties. Advantages of the Backlack process: The Backlack process offers several advantages over alternative packaging processes, which we will discuss in detail below. Precision – Sheets coated with baking varnish are baked over the entire surface. This means that even delicate slats can be assembled precisely.

Request for a quote

TEPROSA GMBH

Germany

TEPROSA GmbH has specialized for many years in the manufacture of sophisticated, precisely fitting laminated cores of exceptionally high quality. In the field of electrical steel sheet, we manufacture individual laminations and sheets for stators and rotors, as well as entire sheet packages stator- or rotor packages) from various steel grades. We process grain oriented electrical steel for generators, transformers and other electrical machinery. Our most common method for packaging the individual laminations is baked enamel technology. Alternatives are welding or bolting of laminations. As a long-standing supplier to various OEMs, the quality of our work is particularly important to us. Therefore, we work according to uniform processes and thus ensure consistent quality and complete traceability of each individual production step.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

On request, we can supply ball caster tables / ball transfer units tables adapted to your individual requirements. We usually use sheet metal panels, which are manufactured, edged and welded on all sides, in accordance with your size specifications. The standard table models are galvanised, but can also be supplied with powder-coated surfaces in different RAL colours, in bright steel or stainless steel. Ball caster spacing patterns are manufactured in accordance with your individual requirements. We supply every size of table. In the case of surfaces larger than 2,000×3,000 mm, several table plates are put together to make one table. The ball casters / ball transfer units are mounted by means of press fitting and are easily replaceable. They can be mounted in rows or positioned alternately.

Request for a quote

CRAEMER GMBH

Germany

Craemer is a specialist for constructing and manufacturing complex metal components and a well-known international supplier for the automotive, commercial vehicle, large domestic appliance and heating industries. The sheet metal components are sold to leading car producers, such as BMW, Mercedes Benz, GM, Volkswagen and Audi. Miele and other world brands are being supplied with white goods. The Craemer Group is one of the leading European manufacturers in the high volume serial production of car-modules, particularly components for seating structure and seatbelts. We process: sheet steel, high-strength sheet steel, high-grade steel and aluminium sheet Manufacturing process: hydraulic and mechanical presses with progressive die, transfer and servo direct technology as well as modern facilities for assembly production. Press capacity of between 3,150 and 25,000 kilonewton at a maximum table-length of 8,000 millimeters

Request for a quote

MECHASYS GMBH

Germany

lasercutted sheets bended in hard-tool for mid-range batches, high flexible, batches from 1.000 - 50.000 parts

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

These consists of a multitude of individual components, such as Our piping and duct systems are dimensioned and designed taking into account aspects of flow dynamics and energy. Depending on the intended purpose of use, they are manufactured from galvanised sheet steel, from thick-walled sheet steel (painted or hot-dip galvanised), from stainless steel or from plastic.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

For Fast and Economical Instant Manufacturing of Sheet Gaskets Characteristics Fast and flexible solution for a whole range of applications Easy and safe operation Round shapes cutting from 30 up to 1000 mm Suitable for various sheet thicknesses up to 9 mm Also small sized sheet pieces are processable Spare parts on request Version W5FDKS300 simple solution for easy and infrequent use for gaskets with a max outer diameter of 300 mm.

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

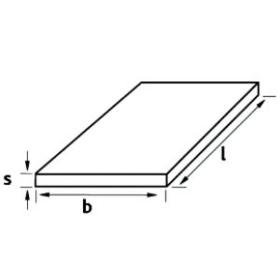

Form: sheet Material: 1.4301 (X5CrNi18-10) Manufacturing method: cold-rolled, 2B Surface finish: pickled Norm: EN 10088-2 Dimensions: Thickness (mm): 0.4 - 8 Length (mm): 2,000 - 6,000 Width (mm): 1,000 - 2,000 Foliation: Foil 4228, no foil, laser protection foil, no paper

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4828 (X15CrNiSi20-12) Manufacturing method: cold-rolled, 2B Surface finish: pickled Norm: EN 10095 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 1 - 3 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4301 (X5CrNi18-10) Manufacturing method: hot-rolled, 1D Surface finish: ground Norm: EN 10088-2 Ground sites: on one side Grain: Grit 240 Dimensions: Gauge (mm): 10 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4016 (X6Cr17) Manufacturing method: cold-rolled, 2B Surface finish: pickled Norm: EN 10088-2 Dimensions: Thickness (mm): 3 - 4 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500 Factory filming: no film, no paper

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4301 (X5CrNi18-10) Manufacturing method: hot-rolled, 1D Surface finish: pickled Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 3 - 12 Length (mm): 2,000 - 6,000 Width (mm): 1,000 - 2,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4541 (X6CrNiTi18-10) Manufacturing method: cold-rolled, 2B Surface finish: cold-rolled pickled Norm: EN 10088 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 1 - 4 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4301 (X5CrNi18-10) Manufacturing method: cold-rolled, 2R Surface finish: bright annealed Norm: EN 10088-1-2-3 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 0.5 - 3 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500 Factory filming: Standard film, no film, laser protection film

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4541 (X6CrNiTi18-10) Manufacturing method: hot-rolled, 1D Surface finish: pickled Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 3 - 12 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

SANER PLASTIC

Germany

Our solid polycarbonate sheet is manufactured through the extruder line. Because the solid polycarbonate sheet is isolated by a clean room, it is packaged away from the ambient conditions and which presents as high-quality standards of error-free products. Through the addition of masterbatch, the extruder allows you to capture the color and tone you want. The solid polycarbonate sheet, that come out of this machine, are available to be sold in the thickness range between 2mm – 20mm. All solid polycarbonate sheet products are in compliance with the European product norms and have the required customs certificates for the EU. Benefits of Solid Polycarbonate Sheets: - Polycarbonate sheet can withstand force and is almost unbreakable - It is durable and light in weight - It is resistant to heat, sun light, snow and rain - UV protection feature can be added to this product. - The sheets can be produced with various vivid colours and last many years without fading or discolouring.

SANER PLASTIC

Germany

PMMA High Precision Acrylic Sheet is manufactured from the high precise extruder line. Due to the fact that the extruded pmma sheet is isolated by a clean room, it is packaged away from the ambient conditions. Thus the extruded acrylic sheet presents error free high-quality standards. Through the addition of masterbatch, the extruder allows you to capture the color and tone you want. The extruded pmma sheets are available to be sold in the thickness range between 1,5mm – 20mm. Extruded PMMA High Precision Acrylic Sheet Benefits: - Fast and low-cost production - High quality production at low tolerances - Production and direct palletizing - Quick and practical product size changeover due to direct manipulation - High efficiency through the usage of recycled material.

Results for

Sheet manufacturer - Import exportNumber of results

21 ProductsCountries

Company type