- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sheet bending

Results for

Sheet bending - Import export

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

GSW SCHWABE AG

Germany

When you deal with industrial surface treatment and your expertise is the cleaning, brushing, polishing or coating of strip steel, you most likely do not want to spend any worries about the run of the material. That’s where our Winding Lines keep your worries away – because they take care of a safe run! They work with high tension and special monitoring and deflectors to do this, with the result of a clean wound beginning to end. The machine design thus calls for especially high drive power and precision expansion systems; even something so simple as the machine base is designed special to cope with the forces… To control the precision of one layer to the next, we utilize external edge controls and servo-drive the Reels for adjustment. This way we meet the typical low tolerances in this industry – after all, the coil is the product!

Request for a quote

GSW SCHWABE AG

Germany

With Conventional Feed Lines, the focus lies on speed and material surface. That’s why Conventional Feed Lines are equipped with a Coil Reel for pull-off, a Straightener with variable frequency drive a coil loop and a Servo Roll Feed: the loop uncouples the more inert straightening process from the highly dynamic indexing process and thus allows for high line speeds and preservation of the material surface. Since productivity and capacity demands can vary significantly, we have created different control concepts: while small Feed Lines work with a simple pneumatic drag brake at the Coil Reel and an ultrasonic sensor to control the Straightener speed, the large Feed Lines get fully synchronized controls with motor-limited Coil Reels and a smart loop, creating a steady average speed of the whole line. This allows smooth pull-off of high coil weights while the loop remains very calm – in addition, the Servo Roll Feed can work with full dynamics, even at long indexing progressions.

Request for a quote

GSW SCHWABE AG

Germany

A perfect combination of space savings and dynamics: the GSW Compact Feed Lines Our Compact Feed Lines are an ideal answer to the challenge of a constraint floor and necessity to process thick materials. Marrying the processes of leveling and indexing into one Feeder-Straightener machine allows for a complete Feed Line with only two individual machines and thus greatly reduces the necessary length. Additionally, the decoupling of the coil mass from the indexing process – achieved through a short loop between Coil Reel and Feeder-Straightener – enables dynamic feeding despite the compact footprint. And, if cross-sections are especially big, the loop can be spared completely, creating yet more space. One more advantage, virtually a by-product out of their very nature, is the quicker set-up of our Compact Feed Lines. This elevates them to not only space- but also time-savers!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RONIX GMBH

Germany

The Ronix RH-1440 sheet metal locking plier is a quality product from the varied collection of Ronix hand tools and sheet metal pliers. This tool is used to hold and move sheet metal, bend the corners of workpieces, curve the edges of parts, and clamp and hold sheet metal to be welded while working. The Ronix RH-1440 8-inch sheet metal clamp is made from high-quality stainless steel. In addition, its wide, machined, standard-size jaws are designed to hold the part in position. The clamping force of this tool is evenly distributed, so the sheet metal is not damaged during transport

Request for a quote

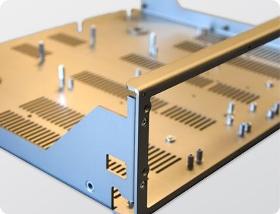

MECHASYS GMBH

Germany

lasercutted sheets bended in hard-tool for mid-range batches, high flexible, batches from 1.000 - 50.000 parts

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Universal forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming and straightening. The many special features of the Kraftformer KF 675 Magnum include stroke speed preselection and stored machining programmes for reproducible results. The Kraftformer KF 675 Magnum is capable of machining large steel components with a sheet thickness of up to 6 mm. A single Kraftformer is all you need to bend profiles, form sheet metal, produce new parts, and repair or rework workpieces with high precision. For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). • Preselection of stroke speed • Adjustable return position • Stores up to 25 user-defined machining programmes • Reproducible results • Tool check • Electronic fault diagnosis • Servo motor-driven machine Max. forming capacity Steel 400 N/mm²: 6.0 mm Aluminium 250 N/mm²: 6.0 mm Inox 600 N/mm²: 4.0 mm

Request for a quote

HPM TECHNOLOGIE GMBH

Germany

SURVOS products are optimally suited to sheet metal forming, machining and assembly technology. Our SURVOS has also been successfully used in cutting and punching aluminium sheets, steel sheets, copper and brass sheets, in cold profiling, bending, embossing, sawing and drilling aluminium profiles for decades. SURVOS Plus L meets the strict food law requirements of the FDA US regulations in acc. with 21 CFR 178.3620(b) and 178.3120. SURVOS Plus has a high lubricity and quickly evaporates 100%.* * According to the specifications of the DAB (German Pharmacopoeia), an evaporation residue of < 0.01% is considered to be residue-free. The evaporation residue of SURVOS Plus L is 0.0045% or 45 ppm.

Request for a quote

HPM TECHNOLOGIE GMBH

Germany

SURVOS products are optimally suited to sheet metal forming, machining and assembly technology. Our SURVOS has also been successfully used in cutting and punching aluminium sheets, steel sheets, copper and brass sheets, in cold profiling, bending, embossing, sawing and drilling aluminium profiles for decades. SURVOS – 100% residue-free* evaporating metal processing oil. SURVOS Rapid D evaporates considerably faster than the "Standard" formulation (with a somewhat lower lubricity). SURVOS Rapid D impresses, however, with short evaporation times and is 100% residue-free*. The fluid is used in particular when operations follow each other in a short cycle sequence and no residue is allowed to remain. * According to the specifications of the DAB (German Pharmacopoeia), an evaporation residue of < 0.01% is considered to be residue-free.

Request for a quote

HPM TECHNOLOGIE GMBH

Germany

SURVOS products are optimally suited to sheet metal forming, machining and assembly technology. Our SURVOS has also been successfully used in cutting and punching aluminium sheets, steel sheets, copper and brass sheets, in cold profiling, bending, embossing, sawing and drilling aluminium profiles for decades. SURVOS detaches from a workpiece with 100% residue-free evaporation even when the parts lie flat on top of each other. Only selected raw materials of the highest purity are used for SURVOS. One of the main components is dearomatized hydrocarbons of the highest quality. As a metal processing medium that evaporates residue-free, SURVOS combines optimum lubricity with favourable values for evaporation speed, toxicology and environmental protection. All SURVOS products are classified according to REACH (EC 1907/ 2006) and do not contain any substance that is on the list of candidates for SOVHC.

Request for a quote

HILGEFORT GMBH

Germany

Hilgefort processes steels, special steels, aluminium and copper. The machinery can be used to process sheet thicknesses ranging from 2 mm to 300 mm. The maximum dimensions for one-piece components are a diameter of up to 7 m and a length of up to 100 m. Larger assemblies are manufactured in segmented designs. This facilitates movement of unit weights up to 300 tons on the rotary devices (hydraulic lift for loading the trailer). The capacity of each of the hall cranes is around 100 tons of unit weight. The modern machinery available at Hilgefort for metal processing includes the following: Fine plasma/oxy-fuel cutter, 3.5 m x 28 m Three-roll bending machine, 3.0 m x 12 mm sheet thickness for vertical processing Four-roll bending machine, 3.0 m x 80 mm sheet thickness Four-roll bending machine, 3.0 m x 35 mm sheet thickness Three-roll bending machine, 3.0 m x 12 mm bending thickness Three-roll bending machine, 1.5 m x 5 mm bending thickness Three-roll bending machine, 1.2 m x 3 mm...

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

With our CNC-controlled folding machine HFE M2 5020 from Amada, we bend aluminium, steel or stainless steel in the sheet metal area perfectly into your desired shape. Depending on the material thickness, we process sheet metal up to a width of 2000 mm.

Request for a quote

GÖCKE GMBH & CO. KOMMANDITGESELLSCHAFT

Germany

Canted profiles in XXL We cant almost every profile with our special tools. Most of the machines used at Göcke are specially constructed; tools for the sheet metal bending presses as well as stencils for sheet metal blanks are self-produced in-house at Göcke. At Göcke Umformtechnik, every desire of the customer and wish for appointments is turned into reality on modern DNC-controlled sheet metal bending presses. For this, we have available an extensive store depot, even special grades. - Cant profiles up to 21 m - Presses up to 3,000 t

Request for a quoteResults for

Sheet bending - Import exportNumber of results

15 ProductsCountries

Company type