- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- servo lines

Results for

Servo lines - Import export

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

COSY ELECTRONICS GMBH

Germany

Normally two separate connectors are used for power and signal lines for servo drives. The new reduced size connection system from ITT Cannon combines power and signal lines into one zinc die-cast housing. This reduces the number of individual components as well as the cabling time and costs are cut. The innovative design simplifies the assembly and is a plus factor compared to the solution with circular connectors, with 50% less weight and size. For these reasons it is the ideal connection system for applications where there is not much space available. The CmX series fulfils all requirements according to DIN EN 61984. There are three sizes: Cm2, Cm3 and Cm5 with 16 up to max. 30 contacts.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

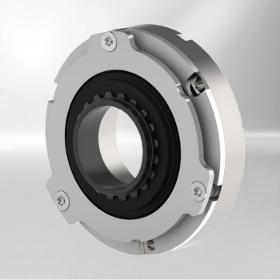

The spring-applied single-disc brakes in the Servo Line series are designed to operate dry. They can be mounted to the A-face or B-face end shield inside the servo motor. The braking action generated by the compression springs is neutralized by applying the electromagnetic principle involving generation of a magnetic field. The brakes engage in unpowered condition and release when DC voltage is applied. The brakes are equipped with a flange and firmly fastened with screws. Thanks to a specially developed and patented manufacturing method, the rated air gap tolerance can be reduced to a few hundredths of a millimetre, providing enhanced power. Moreover, the brakes have a toothed hub/friction disc connection with minimal circumferential backlash. Standard version is suitable for flange mounting and face mounting.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The spring-applied brakes which are ideally suited for robotics is designed for robotics solutions and loads of up to appr. 20 kg, but it can also be used in other applications requiring small geometrical dimensions. With regard to their power density the slim single-disc brakes are flatter and lighter than the market standard, and due to their large inner diameter they are well suited for hollow-shaft drives. This makes them perfect for applications in lightweight robots with integrated drives. There is a growing demand for safety technology in order to avoid injuries by collisions, especially if the control technology or even the power supply fails. In this case electromagnetic brakes are usually the method of choice. As safety brakes they bring moving masses to a stop, keep loads in position and therefore prevent humans and material assets from being affected.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Servo lines - Import exportNumber of results

4 ProductsCountries

Company type