- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- separating

Results for

Separating - Import export

CIC - KLAUS CZERWONKA

Germany

Filter + filter water separator Sizes: 1/8" and 1/4" Filter fineness: 5 µm + 0.01 µm Flow rate at 6 bar with ∆p 1 bar: 370 Nl / min Pressure range up to 15 bar

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Water Separator WA Connect. G1/2 ... G11/2 application with wet or moist surfaces

Request for a quote

SCHOCK GROUP

Germany

Ball bearing partial extension slides with a 70-80% extension length Load capacity up to 56 kg per pair Standard rail length up to 660 mm Separable inner rail Locking in the open position Closed end stop Manufactured in the European Union For over 40 years, the Schock Group has been developing and manufacturing ball bearing telescopic slides for linear motion technology. The advantageous physical properties of ball guidance form the basis for the performance of Schock telescopic slides: Smooth and quiet operation, even under high loads. High operational reliability Long service life without maintenance Standard items in the specified lengths are available in stock from our distribution partner SToxxparts GmbH, starting from a quantity of one piece. Custom solutions are available through Schock Metall on a project-specific basis. We look forward to receiving your project inquiry, including your annual requirements and anticipated start date for production.

Request for a quote

SCHOCK GROUP

Germany

Telescopic Rail 35.2 x 19 mm, Galvanized Steel, Standard Lengths up to 660 mm, Load Capacity up to 52 kg per Pair Ball Bearing Over-extension Load Capacity up to 52 kg per Pair Standard Rail Length up to 660 mm Separable Inner Rail Locking in Open Position Closed End Stop Manufactured in the European Union For over 40 years, Schock Group has been developing and manufacturing ball bearing telescopic rails for linear motion technology. The advantageous physical properties of ball bearing guides form the basis for the performance of Schock telescopic rails: Smooth and quiet operation, even under high loads. High functional reliability Long service life without maintenance Standard items in the specified lengths are available from our distribution partner SToxxparts GmbH in stock and from a quantity of one piece upwards.

Request for a quote

SCHOCK GROUP

Germany

Telescopic Rail 45 x 12.7 mm, Galvanized Steel, Standard Lengths up to 600 mm, Load Capacity up to 40 kg per pair Full Extension Ball Bearing Guide Load Capacity up to 40 kg per pair Standard Rail Length up to 600 mm Separable Inner Rail The Schock Group has been developing and manufacturing ball-bearing telescopic rails for linear motion technology for over 40 years. The advantageous physical properties of ball bearing guides form the basis for the performance of Schock telescopic rails: Smooth and quiet operation, even under heavy load. High operational reliability Long lifespan without maintenance Standard items in the specified lengths are available from our distribution partner SToxxparts GmbH from stock, and they can be ordered from a quantity of one piece. Custom solutions are available from Schock Metall on a project-specific basis. We welcome your project inquiry, including your annual requirement and expected start date for production.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OSMO MEMBRANE SYSTEMS GMBH

Germany

Oil-water-separation / degreasing bath treatment Treatment of oil-water-emulsions for surface treatment (e.g. pre-treatment of metal parts for ed-paint), recovery companies (e.g. for the treatment of alkaline emulsions for part washing), and so on. Separation of emulgated oil particles and recycling of the cleaned liquid into the degreasing bath Concentration of oil-water-emulsions for disposal Cleaning of the oil-water-mixture for indirect lead-in Principle of this process: Aqueous degreasing baths content a tenside combination, alkalines like soda, caustic soda, phosphate, silicate and further complex molecules. The degreasing bath is loosing its efficiency, when to oil content reaches some g / litre. External pollutions also degrease the degreasing efficiency. By ultrafiltration, the oil content can be separated from the degreasing bath and the oil will be collected in the concentrate. The degreasing bath will be dumped into a buffer tank and then pumped in the working tank of the

Request for a quote

SUVIS GMBH

Germany

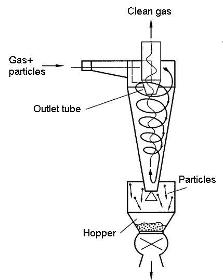

The Suvis GmbH also deals with the application of modern numerical methods for the lay out and optimisation of various separator types like cyclones. A typical application of these computation methods is the computer aided investigation of particle separation from gases in cyclones. The prediction of the separation efficiency allows the reliable optimisation of conventional cyclones and the development of completely novel high efficiency cyclones. With that, very often expensive filter units, wet cleaner, or costly electro filters can be replaced or completed. When applying numerical methods (CFD simulations) to cyclones one encounters the problem of strong curvature of the stream lines because of the resulting strong swirl flow and the abrupt change of flow direction towards the outlet tube. This means that the assumption of isotropic turbulence is not useful anymore.

Request for a quote

SUVIS GMBH

Germany

Hydro cyclone units are applied in order to separate coarse and fine solid particles from liquids . These type of separators are particularly capable of separating sand, starch, and other finely distributed materials. With hydro cyclones it is possible to separate fine particles online during the process. Hydro cyclone units are used to separate, classify, and to thicken suspensions. Also, these units are used to purify ores and minerals. Also, in fibre technique and paper industry they are applied in purification processes to separate dirt. Hydro cyclones are frequently run in parallel mode. The lay out and design of hydro cyclones are performed empirically similar to the duct cyclones. In the lower flow region of a hydro cyclone an air swirl forms during the separation process, which is not substantially influencing the cyclone flow. Because of the large dimension of the cyclone, wall friction has much more influence on the flow.

Request for a quote

SUVIS GMBH

Germany

The gas cyclone belongs to the mostly applied technical separators, because it has applicationwise some fundamental advantages. One of them is certainly the fact that its construction does not show any movable components. For the large variety of different kinds of dispersed (particulate) phases (for example dust particles, metal chips, wooden waste, liquid droplets) and different gas conditions (pressure, temperature) the lay out and computation of a cyclone is still a complex task. Suvis has specialised in the development and lay out of cyclone separators and can offer professional solutions and consulting in the area of gas cyclones. Many years of experience gained through numerous cyclone development projects results in optimal solutions for our customers. A cyclone separator applies centrifugal forces and represents an effective apparatus for separating gas, liquid or solid particles from a continuous phase in chemical, process or environmental engineering.

Request for a quote

J+R WIRTHS LOGISTIK GMBH & CO. KG

Germany

This allows us to store a wide variety of product types and product groups, from different raw materials to various products for fulfilment.

Request for a quoteResults for

Separating - Import exportNumber of results

11 ProductsCountries

Company type