- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ring

Results for

Ring - Import export

CIC - KLAUS CZERWONKA

Germany

According to DIN2353 for pipe connections up to 60 bar

Request for a quote

IGUS® GMBH

Germany

When to use piston rings? When piston rings with excellent wear properties are required When simple assembly is of great importance When high edge loads occur When tailor-made solutions based on iglidur® materials are required When not to use piston rings? When the piston rings should seal simultaneously When different diameters should be covered by one part Before: with piston rings: Why complicate things when it can be done differently? Replace elaborately stamped PTFE tapes with a single clip-on guide ring, such as in lifting elements, control valves and fittings. We offer iglidur® piston rings made of freely selectable materials for a wide range of applications. Special properties Easy to assemble Low-priced More wear-resistant than PTFE-bonds Higher load capacity Defined dimensions different materials per ex. iglidur® J, J350… iglidur® piston rings - application examples When to use piston rings? When piston rings with excellent wear properties are required When simple assembly is of great importance When high edge loads occur When tailor-made solutions based on iglidur® materials are required When not to use piston rings? When the piston rings should seal simultaneously When different diameters should be covered by one part Installation recommendations pistons installation recommendations for housings Installation recommendations for housings Dimensions [mm] dS (h-tolerant) [mm] dG (h-tolerant) [mm] bg [mm] Nominal diameters dS = d1 dG = d2 bG = b1 +0,2 Installation recommendations for pistons Dimensions [mm] dG (h-tolerant) [mm] dH (h-tolerant) [mm] bg [mm] Nominal diameters dG = d1 dH = d2 bG = b1 +0,2 b1: Desired length Inner and outer Ø (d1 and d2) made using standard plain bearings* M for metric PRfor piston ring iglidur® desired material

Request for a quote

BDP MECHANICAL COMPONENTS DEUTSCHLAND GMBH

Germany

Used in train, made by sand casting and machining, material EN GJS 400, size 234mm x 56mm, weight 3,8kg, annual demand 500.000pcs

Request for a quote

SYSKOMP GMBH - EMICO

Germany

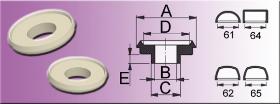

Washers for snap-on caps. These rings are applicable for cap type: 66 Material: PA Colours: natural Ring type 69 suitable for DIN 95, 97, 963, 964, 965, 7963, 7972, 7982, 7983, 7991, 7995 ISO 1482, 2009, 2010, 7046, 7047, 7050, 7051, 10642. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap type: 66 Material: PA Colours: natural Ring type 67 suitable for DIN 84, 85, 96, 439, 6912, 7971, 7981, 7984, 7996 ISO 1207, 1481, 1580, 4035. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap type: 66 Material: PA Colours: natural Ring type 66 suitable for DIN 84, 85, 96, 439, 6912, 7971, 7981, 7984, 7996 ISO 1207, 1481, 1580, 4035. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap types: 61, 62, 64 and 65. Material: PA Colours: natural Ring type 65 suitable for DIN 84, 85, 96, 439, 555, 558, 571, 601, 912, 931, 934, 979, 6912, 7971, 7976, 7981, 7984, 7996 ISO 1207, 1481, 1580, 4014, 4016, 4018, 4032, 4034, 4035, 7049. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap types: 61, 62, 64 and 65. Material: PA Colours: natural Ring type 63 suitable for DIN 95, 97, 963, 964, 965, 966, 7963, 7972, 7982, 7983, 7991, 7995, 7997 ISO 1482, 2009, 2010, 7046, 7047, 7050, 7051, 10642. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap types: 61, 62, 64 and 65. Material: PA Colours: natural Ring type 61 suitable for DIN 84, 85, 96, 439, 555, 558, 571, 601, 912, 931, 934, 979, 6912, 7971, 7976, 7981, 7984, 7996 ISO 1207, 1481, 1580, 4014, 4016, 4018, 4032, 4034, 4035, 4762, 7049. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap types: 61, 62, 64 and 65. Material: PA Colours: natural Ring type 60 suitable for DIN 84, 85, 96, 439, 555, 558, 571, 601, 912, 931, 934, 979, 6912, 7971, 7976, 7981, 7984, 7996 ISO 1207, 1481, 1580, 4014, 4016, 4018, 4032, 4034, 4035, 4762, 7049. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

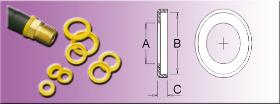

Washers with flange Wall thickness: 8.13 mm Material: LDPE Colour: yellow

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Sealing Rings DR for Thread G1/8 ... G11/2

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

This rugged and reliable liquid ring compressor expaned the NASH Vectra compressor range with a model that operates at up to 4 bar G (60 PSIG). The XM-150 comes in 681 and 682 compliant versions and is specifically designed for the higher pressures and performance requirements found in many process applications, including vapor recovery, flare gas recovery, biogas, corrosive gas handling (e.g. VCM and chlorine) and hydrogen compression. The NASH Vectra XM-150 liquid ring compressor provides the same quality and reliability you've come to expect from the existing Vectra series with these features: Single, conical port design; Between bearing rotor/shaft design; single pressure boundary sealing point; API-681 and API-682 category II/III compliance; increased bearing life; 316 stainless steel construction; and horizontal, self-draining inlet/discharge nozzles. The rugged construction and easy to service design of this liquid ring compressor reduces maintenance requirements and minimizes downtime for maintenance and repairs in even the most demanding applications.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

15 - 140 CFM / 35 to 210 m³/h Designed from the ground up to meet the widespread needs of the process industry, the Vectra SX adds five models to Nash’s Vectra series in the 1 ½ to 10 HP range at 60 Hz (0.75 to 5.5 kW at 50 Hz), providing the right solution for small capacity vacuum pump requirements. Designed to use less energy and consume less operating liquid than competitive models, it is possible to save the user as much as 40% on power consumption and 50% on water usage.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

120 - 5300 CFM / 195 to 9,000 m³/h The NASH Vectra was designed around a modular platform using the most advanced computer aided design techniques, such as 3D solid modeling and finite element analysis (FEA). The modular platform offers the advantage of two versions with numerous common parts. The Vectra GL model, available from 120 to 830 CFM (200 to 1,500 m³/hr), is ideal for general industrial applications. It comes standard with internal mechanical seals and many Nash patented innovations including gas scavenging. The Vectra XL model was designed to meet the stringent requirements of many CPI applications. Whether operating as a vacuum pump or compressor, it features a 30 PSI (2 bar) differential capability. It is available in ductile iron or 316L stainless steel with a variety of shaft sealing options. Sizes range from 120 to 5,300 CFM (200 to 9,000 m³/hr). The NASH Vectra can be operated within a wide range of operating speeds, with numerous 50 and 60 HZ direct drive speeds. This increased turndown capability makes them ideal for varying load applications when driven by VFD's.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

1800 - 2600 CFM / 3,050 to 4,400 m³/h Found primarily in petroleum refineries and chemical plants, this rugged and reliable compressor handles highly toxic, explosive and corrosive gases in applications such as flare-gas, chlorine and Vinyl Chlorine Monomer (VCM) recovery. Together with the 14 new GARO models and other NASH liquid ring compressors, the NASH HP-9 compressor form the NASH core compressor product line, which provides compression greater than 200 psig (15 Bar abs). Low pressure compressors are available to 30 psig (3 Bar abs), and 20,000 CFM (34,000 m³/hr). As a result, NASH offers the widest pressure and capacity ranges of liquid ring compressors available worldwide.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

100 - 1800 CFM / 170 to 3,050 m³/h The GARO line of liquid ring compressors expands the capacity and pressure ranges of the Nash line to meet the ever growing requirements of our customers. Found primarily in petroleum refineries and chemical plants, these rugged and reliable compressors handle highly toxic, explosive and corrosive gases in applications such as flare-gas, chlorine and Vinyl Chlorine Monomer (VCM) recovery. The GARO line, available in single and two-stage designs, comes in: cast iron, stainless steel, carbon steel, spheroidal cast iron, 316 stainless steel, duplex stainless steel, and Hastelloy or Titanium on select models. Together with other NASH liquid ring compressors, including the HP-9, the 14 GARO models form the NASH core compressor product line, which provides compression greater than 200 psig (15 Bar abs). Low pressure compressors are available to 30 psig (3 Bar abs), and 20,000 CFM (34,000 m³/hr). As a result, NASH offers the widest pressure and capacity ranges of liquid ring compressors available worldwide.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Suction capacity 6,000 to 11,00 m³/h The NASH 2BQ1 590 has a unique performance range. It combines a high gas flow rate (6,000 to 11,000 m³/h) with a discharge pressure range of up to 3.75 bar abs. The standard 2BQ compressor model is equipped with a duplex steel shaft, ductile iron end shields, a massive stainless steel housing and o-rings to seal housing components. Higher quality materials are available on demand by using the modular 2BE3/4 design. The NASH 2BQ1 is certified for ATEX.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Suction capacity 125 to 1400 m³/h; Vacuum to 33 mbar abs.; Discharge pressure to 2.0 bar abs. The NASH 2BM1 magnetic drive pump series is capable of achieving volume flow rates of 125 to 1400 m³/h and vacuum of 33 mbar abs. Non-contact torque transmission is achieved by using a permanent magnetic drive system. The pump's inner working space is hermetically sealed from atmospheric conditions, eliminating any possibility of leakage. This seal is essential for demanding applications, such as processes that are required to meet the most stringent standards on environmental compatibility. ATEX applications are also possible, certifications are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

The NASH 2BE5 was developed from the proven NASH 2BE3 and 2BE4 compressors, whose reliable performance has been further improved. The development focused on optimizing performance, higher vacuum capabilities and ease of maintenance. NASH 2BE5 Benefits include: improved efficiency higher vacuum levels (to 100 mbar abs / 3" Hg abs) built-in ECO-FLO™ water saving technology with patent pending gas scavenging drop in replacement for 2BE3 and 2BE4 removable bearing brackets for easier maintenance elimination of tie rods, resulting in improved sealing due to bolted casing joints polyisoprene lining The footprint and connections to the NASH 2BE5 models are identical to its predecessors, the NASH 2BE3 and 2BE4. Therefore, exchanging or upgrading to the more efficient NASH 2BE5 requires no site modifications. The NASH 2BE5 model is available in cast iron, with stainless steel coming soon. The 2BE5 is perfect for use in mining, filter applications, paper mills, power plants, chemical plants, refineries and more.

Request for a quoteResults for

Ring - Import exportNumber of results

21 ProductsCountries

Company type