- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing

Results for

Processing - Import export

SCHOCK GROUP

Germany

Due to own production sites with modern machinery your customer requirements can be effectively considered and realized.

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Contaminated bulk material is cleaned One of the most annoying and expensive problems with bulk material processing is the contamination by foreign substances. These contaminants not only reduce the quality of the final product, they also cause damage to the machines and failures. Especially high-strength small metal parts such as screws, nuts, washers, or cotter pins cause serious damage to the processing machinery. For this reason, the production costs with contract processing are often uncontrollable. Ebbecke has the production under control To solve this costly nuisance, the engineers of Ebbecke Verfahrenstechnik AG have developed their own system with which goods that have been contaminated by metal particles can be cleaned. This is done using the inductively-working metal detector that detects even the finest metal abrasions and reliably separates them from the goods. Through a trouble-free production process delays, non-compliance of supply contracts and consequent compensatio

Request for a quote

ACTIVE ANTS

Germany

Returned items are inspected, restored to their original condition and re-stocked. Our returns process meets the strict guidelines of platforms like Zalando and Amazon. If you also sell through these platforms, this is extremely convenient.

Request for a quote

MBW GRUPPE

Germany

"In phosphating, a phosphorus-containing crystal coating is applied to steel parts and galvanised steel parts by a chemical surface process. There are various phosphate processes, e.g., zinc phosphate, zinc calcium phosphate, iron phosphate. The coating thickness is adjustable for special customer requirements. Beim Phosphatieren steht die Verformbarkeit und die Bildung eines Haftgrundes im Vordergrund. During phosphating processes, the formability and the formation of an adhesive primer is of primary importance. The coating weight is usually in the range of 1 to 15g/m². Phosphatisations are especially resistant to lubricants such as oils or greases, and therefore well-suited to many technical applications. . Phosphate coatings are usually further coated. This involves: Oiling, soaping, lubricant coating, vulcanising and painting."

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Through a representative office in Hong Kong, CIC supports the often difficult procurement of technical products from China, e.g.: efficient search for suitable suppliers direct, native speaker contact with the producer Contract design and processing Supplier Qualification Quality monitoring Logistics control ZURÜCK

Request for a quote

SUVIS GMBH

Germany

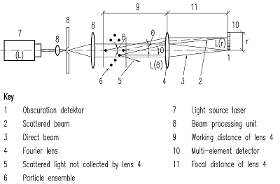

In various chemical or physical and technical processes particles of the order of 1 μm up to a few mm in size appear, whose size distribution is decisive or important for the process. There are many technical examples like in food production, pharmacy, process engineering, fuel burning in turbines, motors etc., slurry burning, and cosmetics. The laser diffraction particle sizer is capable to measure a particle size distribution from a collective of particles like a spray and to appropriately process, describe, and present it. The particle material may be solid or liquid in a gas or gas like air bubbles in a liquid. For the measurement it is only important, that the optical properties of the continuous and the dispersed phase are different. The laser diffraction particle sizer offers the advantage of a fast and non invasive measurement in a wide range of particle sizes. Especially in case of sprays or suspensions this method has become a standard measurement tool.

Request for a quote

DRESSLER GROUP

Germany

Two current examples of Dressler Group innovations: Spherical Powder Technology (SPT) and the development of integrated processes. SPT is a process that allows powders to be made out of high-performance polymers that cannot otherwise be pulverised. This opens up completely new kinds of applications, using processes such as 3D printing/additive manufacturing, that were equally impossible before. Meanwhile, integrated processes allow grinding, sieving and dust removal to be carried out in a single operation rather than separate steps, thus saving energy and time.

Request for a quote

DRESSLER GROUP

Germany

Dressler Group (DG) has four brand values: flexibility, quality, innovation – and service. The last point is so important, a Dressler subsidiary bears its name: Dressler Group Customer Service. After all, the family business is renowned for its absolute customer focus. The best way to get to know Dressler Group is in person: Your contacts: Jan Dressler, CEO, COO: jan.dressler@dressler-group.com Christian Manteuffel, Team Manager Sales: manteuffel@dressler-group.com Alexander Leis, Staff Member Sales: leis@dressler-group.com

Request for a quote

DRESSLER GROUP

Germany

At our Technical Centre, which has proven its worth over many years, even the smallest quantities bring you great benefits. With an area of over 1,000 square metres, we offer the perfect facilities to verify how the raw materials will actually behave in the intended processes and finishing steps. In addition, we run scalable test series to generate reliable data for calculating costs. The process in three steps: 1. Pilot trial: testing on the smallest scale 2. Scale up trial: testing on the high-performance universal mill, with close support from our experts 3. Large-scale production: testing on the large plant for production on an industrial scale

Request for a quote

DRESSLER GROUP

Germany

DG Mixing process which under the application of high speeds injects enough energy into a powder quantity to create a stable compound from different types of powders and grain particles. Used, for example, for coating surfaces of one type of particle with other particles.

Request for a quote

DRESSLER GROUP

Germany

Fine grinding of dry products is a core competence of the Dressler Group. An extensive range of machine and system programs are available for this, offering the right solution for almost all applications. Finenesses from 1 μm (d97) and into the millimetre range can be reproduced here.

Request for a quote

DRESSLER GROUP

Germany

Method for determining the grain size; air jet sieve, vibrating sieve, but also used in a production system for separating the coarse component of a powder so as to obtain the desired grain size distribution. Using acceleration to separate particles of different weights and therefore mostly different sizes.

Request for a quote

DRESSLER GROUP

Germany

Recording of data and events in written form for later reference. Full documentation is important for all stages of an order. All relevant data is documented and archived, from order entry, production, quality assurance to dispatch. This ensures that the individual processes can be traced back.

Request for a quote

DRESSLER GROUP

Germany

DG Grinding processes with simultaneous cooling of the raw material to temperatures far below ambient temperature (e.g. minus 30°C); usually done with the help of liquid nitrogen, which has a temperature of around minus 196°C.

Request for a quote

DRESSLER GROUP

Germany

Plastics processing through the homogeneous mixing of additives, particularly in extruders at temperatures above the melting point.

Request for a quote

DRESSLER GROUP

Germany

We grind our customers products at temperatures below room temperature.

Request for a quote

DRESSLER GROUP

Germany

At our Innovation Lab, we develop entirely new processes when the desired results cannot be achieved with standard solutions. Our customers can practically watch over our shoulder and participate in the process to the extent they choose. The results are then put to the test in the adjacent Technical Centre. Sometimes this opens up whole new business areas for our customers. Getting more than they bargained for – that’s one more thing our customers appreciate.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DRESSLER GROUP

Germany

We developed a special process for making fine powder systems and composites from low-viscosity melts. With the patented cryo-spraying process CSP, it has become possible to produce highly sensitive products directly from a hot melt to form a solid powder without after-cooling. The entire spraying process is overlaid with nitrogen and also protects very critical substances against oxidation and thermal stress.

Request for a quote

EBINGER KATALYSATORSERVICE GMBH & CO. KG

Germany

Moreover, in Europe we can always offer transportation of the catalysts from the client to our plant and back after regeneration. Since the founding of our company, we have been working with a partner who has extensive experience in dealing with the often sensitive goods. Transportation is always undertaken by using air-suspended vehicles and skilled personnel. We also have experience with sea transports. For example, the logistical processing for the regeneration of catalysts from the Finnish Meri-Pori (200 m³) did not cause any problems and was carried out on schedule during a three-week shutdown.

Request for a quote

DEEPSIGHT

Germany

From procurement to cleansing and enrichment to in-depth analysis of large text datasets.

Request for a quote

ERTEMES GMBH

Germany

A fully equipped computer that can be used to record data from connected Dragonfly amplifiers. Depending on the number of connected devices and CPU power, data can also be processed for real-time monitoring and forwarded to a network-connected PC or laptop. •,Different CPU versions (Core i3, i5 or i7) are available. •,Internal SSD stores data from connected Dragonfly amplifiers •,12V power supply (also possible via Dragonfly battery) •,Ideal for systems that record data autonomously over a longer period.

Request for a quote

REILING GMBH & CO. KG

Germany

As wood recycling experts, we supply you with wood chips produced through our careful processing. Our extensive experience, strict initial checks, and commitment to environmental conservation make us your reliable partner. These wood chips find applications in various industries. High-quality standards: After meticulous processing in our recycling facility, the wood chips are stored in covered bunkers to minimize residual moisture. The selection of wood types for specific uses depends on contaminant levels (e.g., from coatings). Rigorous initial checks and laboratory testing ensure safety. Versatile applications and environmentally friendly Contact us today for more information and offers! Your contact person: Anna-Katharina Hinz | Sales Manager Wood Tel.: +49 2383 936031 E-Mail: a.hinz@reiling.de

Request for a quote

REILING GMBH & CO. KG

Germany

“We all need to use the natural resource wood responsibly, to protect our forests and the climate by extension!” INDIVIDUAL AND CUSTOMIZED: OLD WOOD COLLECTION AND RECYCLING We assist in disposing of your old wood waste (Categories I – IV) – from single-use pallets to fencing. We offer tailored services: collection/disposal through the Reiling fleet or provision of collection containers; pickup can be flexible or on-demand. For commercial quantities, our 24-hour acceptance is open daily. Using innovative techniques and rigorous controls, we process old wood for various purposes. Our end product is wood chips used in the chipboard industry or to generate carbon-neutral energy in power plants. Contact us for more information or quotes! Your contact person: Anna-Katharina Hinz | Sales Manager Wood Tel.: +49 2383 936031 E-Mail: a.hinz@reiling.de

Request for a quote

FRIMO GROUP GMBH

Germany

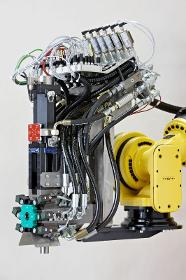

The right mix From basic to high-tech, FRIMO offers peripheral equipment for all PU processing technologies.

Request for a quote

FRIMO GROUP GMBH

Germany

FRIMO PURe Mix mix heads are available as two-component or multiple-component mix heads for various PU product manufacturing. Different sizes for the smallest and the largest output rates are available. FRIMO offers a patented PU spraying system for the production of high quality PU surfaces, such as for automotive interiors.

Request for a quote

FRIMO GROUP GMBH

Germany

The right mix is what counts. FRIMO offers tailor-made mix and metering machines including various standardized modules for PU product manufacturing.

Request for a quote

FRIMO GROUP GMBH

Germany

Flexible and individual solutions FRIMO offers many different solutions in terms of combining tool carriers, mix and metering units, and the peripheral equipment necessary to complete production plants. Individual and turnkey production solutions are therefore highly available.

Request for a quote

FRIMO GROUP GMBH

Germany

Successful for decades and constantly evolving Regardless of the desired kinematics, clamping force or clamping area, FRIMO customized tool/mold carriers can be integrated into single-station or multi-station units, rotary table systems or PURe Track overhead conveyors. FRIMO's more than 1,000 manufactured and delivered tool/mold carriers serve as proof of superior quality and reliability. Special Types: FRIMO is your specialist when it comes to optimal tooling concepts based on customer demands. Our product portfolio covers a broad spectrum of possible special designs, such as window frames, damping units, cast skins, skis, acoustic components, boilers, glass roofs, steering wheels, seat cushions and head rests.

Request for a quote

FRIMO GROUP GMBH

Germany

Form and appearance ideas first become tangible through the help of models. We produce models for all stages of the design and development processes, from the smallest models up to cubing models (e.g. complete automotive interiors). All products are customized and can be designed according to customer requirements .

Request for a quoteResults for

Processing - Import exportNumber of results

36 ProductsCountries

Company type