- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing of stainless steel

Results for

Processing of stainless steel - Import export

RUDOLF GUTBROD GMBH

Germany

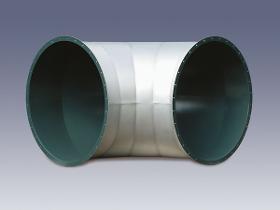

Special and flame retardant Just like ICS, ICS-ETFE is also suitable for coating stainless steel process and utility pipework, for example. As a special, flame-resistant interior coating, this is particularily suitable for the coating of exhaust air pipework, for example, in factories in the chip, solar cell and fibre optics industries. ICS is FM-approved - each construction part is marked separately with the FM specification. This coating is also tested according to the American safety standard Factory Mutual Research 4910 and suitable for use in clean rooms.

Request for a quote

RUDOLF GUTBROD GMBH

Germany

For the best only the highest quality ICS-ETFE is used for coating stainless steel process and utility pipework, for example. As a special, flame-resistant interior coating, this is particularily suitable for the coating of exhaust air pipework, for example, in factories in the chip, solar cell and fibre optics industries. ICS is FM-approved – each construction part is marked separately with the FM specification. This coating is also tested according to the American safety standard Factory Mutual Research 4910 and suitable for use in clean rooms. The coatings are used, amongst other things, in the chemical industry, the electrical industry, the automobile industry as well as in the food industry and in semiconductor technology. ETFE coatings are particularly well suited for use in the semiconductor and pharmaceutical industry. ETFE resists the most extreme conditions, such as e.g. the processing of high-purity grade water (molecules can still be extracted by this even from...

Request for a quote

FILLTECH GMBH

Germany

A very compact, mobile and user-friendly filling system for a wide range of cylinders with weights up to 6 kilograms. Highlights Variable filling connections Easy, precise and safe to operate Automatic filling process Anodized aluminum frame; stainless steel cover plate Optimal cost/performance ratio Build in pump Legal for trade Technical Data Filling-range: approx. 50g - 6kg/ up to 13 lbs. fill weight Weighing- range: up to 15 kg/ 35 lbs. Dimensions: approx. 600 x 400 x 1200 mm/ 24 x 16 x 47 in. Weight: approx. 50 kg/ 110 lbs. Weighing System Two load cells SysTec IT 1000 industrial weighing terminal Automatic tare setting Automatic shut-off at target weight Manually operated relief with ball valve Optional Filling Connections for Pico-Fill Filling unit for 1/2 in. trapezoid- and side-outlet valves Pneumatic press-on, cartridge filler and other connections on demand

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

KB RollerTech processes seamless metal belts (stainless steel and nickel). Compared to coated plastic belts, metal belts offer the following advantages: very high thermal conductivity very high physical stability Today, KB RollerTech processes metal belts with the following properties: Properties Nickel belts Stainless steel belts Length < 350 mm < 400 mm Diameter 15 - 50 mm 10 - 100 mm Wall thickness 30 - 500 µm 35 - 100 µm Geometry straight straight and concave Remarks 100 mm diameter only possible with seam Concerning the coatings the following combinations are possible: Nickel belts Stainless steel belts PFA sleeves PFA spray coatings or PFA sleeves Silicone and PFA sleeves Silione and PFA spray coatings or PFA sleeve

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Plastic Mill The solution for the production of plastic powder Our fine grinding plants for plastic granulates enable the grinding of a wide variety of plastic granulates including even the finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. The ground goods can be processed on site or poured directly into the container specified by the customer. Technical data Target fineness: 200-1,000 µm Plant types: Disc mills, pin mills, granulators, cryogenic grinding plant Container: Bags, Big Bags, octabins, drums or drums Feeding from silo possible Filling from silo vehicles is possible Areas of application Fine grinding of LDPE Fine grinding of polypropylene Fine grinding of polystyrene Fine grinding of polyamide Fine grinding for simultaneous de-dusting of the finished product Fine grinding of EVA under cryogenic conditions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Dry micronization The optimal solution for fine grinding of bulk material We offer you a wide range of different types of plants for contract grinding in our fine grinding centers. Among them are special grinding plants, such as a special mill for natural products, an efficient circulating gas plant and a cryogenic grinding system for temperature-sensitive products. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. Grain size exactly as you request it! Our fine grinding plants enable the dissolution of agglomerates as well as the breaking up of solid grain structures up to the finest grinding in a reproducible product quality. Customers of Ebbecke Verfahrenstechnik AG appreciate the flexibility of the available grinding systems that can be customized to suit the specific requirements of the grinding process. Nothing is left to chance because cutti

Request for a quoteResults for

Processing of stainless steel - Import exportNumber of results

7 ProductsCountries

Company type

Category