- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure equipment

Results for

Pressure equipment - Import export

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

Apparatus for pressurizing test pieces We offer burst test benches to test load-bearing elements under pressure for their resilience. The components to be tested are put under pressure until they burst. Depending on the requirements (e.g. depending on the medium, pressure range, static or pulsating tests) we build your customized test stand.

Request for a quote

SUVIS GMBH

Germany

The particle image velocimetry (PIV) is an optical noninvasive working flow velocity measurement method. The flow field is made visible by introducing into the fluid small buoyancy neutral particles – the so called tracers. The particle flow then is illuminated with the aid of a light sheet and recorded at two defined different times within a small time interval with a digital camera. Because the particle move within this time interval with the flow, one can calculate the particles velocity by knowing its path between the two moments of illumination. The result is a velocity vector field of the flow. Here, we assume that the particles are small and follow the flow without any slip. Compared to local methods like LaserDopplerVelocimetry (LDV) with the ParticleImageVelocimetry one can reconstruct a whole flow region An extension of ParticleImageVelocimetry is the combination of PIV with thermometry (PIV/T).

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

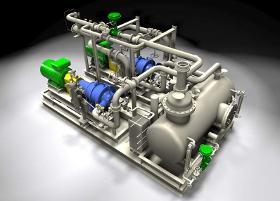

From the first planning to shipment, every project is accompanied by one constant contact person. Depending on industry, process and specification, the best material (steel, stainless steel, duplex materials, titanium, plastic material) is chosen. There is a big importance to consider and meet the different standards and rules. Whether its DIN, ISO, ATEX, GOST ASME or PED (pressure equipment directive) - Nash engineers know all these general frameworks and restrictions. Our team of engineers finds the best solution to realize the customer's requirements.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

All components pass a quality inspection before being used. Many different methods and procedures are used here (e.g. PMI 0 positive material inspection, crack detection). Our scope of machining reaches from chipping/metal cutting to sandblasting (using granule materials) to welding, assembling and painting. We handle many different metallic and nonmetallic materials as steel, stainless steel, duplex materials, titanium, plastic material We give a big importance to welding: Nash employees are certified according to ASME 9 and therefore qualified to manufacture pressure vessels and piping according to Pressure Equipment Directive (DIN EN 3834) and ASME Standards (31.3). Our systems are painted according to customer specification. We work with all wet paints and 2K paints. Anti-corrosion-coatings up to category C5M are possible. Of course, we meet all the other specifications, e.g. regarding coating thickness, as well. The electrical engineering is also done in the Nash location, from design to cabling. After the completion, the system undergoes a pressure test. Furthermore there is an option to do a complete function test to verify the performance data. Nash is certified according to ISO 9001 and ISO 14001.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Pressure equipment - Import exportNumber of results

4 ProductsCountries

Company type