- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal screws

Results for

Metal screws - Import export

OTTO EICHHOFF GMBH & CO. KG

Germany

During re-machining, a cutting tool is used to remove material from a workpiece in order to shape or surface it as required. We offer re-machining (turning, twisting) as wage work. The following machining operations we offer: Turn thin stem, pins and tips Screw punctures, approaches and undercuts Heads of screws / cold shaped parts machining process (turning) further machining operations are possible on request. Our curve-controlled automatic Audrema lathes offer you further possibilities of finishing cold-moulded parts. These automatic lathes are designed to achieve maximum precision and reproducibility at high throughputs. Short loading and unloading times permit economical production of medium-sized and large series.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

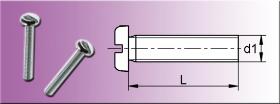

Pan head screws - metal ~DIN 85 (~DIN EN ISO 1580) Material: stainless steel A2

Request for a quote

SYSKOMP GMBH - EMICO

Germany

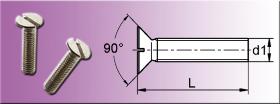

Countersunk screws - metal ~DIN 963 (~DIN EN ISO 2009) Material: stainless steel A2

Request for a quote

SYSKOMP GMBH - EMICO

Germany

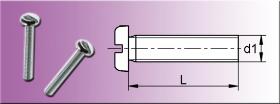

Pan head screws - metal ~DIN 85 (~DIN EN ISO 1580) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

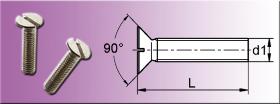

Countersunk screws - metal ~DIN 963 (~DIN EN ISO 2009) Material: machining steel 4.8 zinc-plated

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SYSKOMP GMBH - EMICO

Germany

Hexagon head screws - metal ~DIN 933 (~DIN EN ISO 4017, threaded to head) Material: stainless steel A2

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Lens head screws - metal, cross slot ~DIN 7985 (~DIN EN ISO 7045 - form H) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Lens head screws - metal, cross slot ~DIN 7985 (~DIN EN ISO 7045 - form H) Material: stainless steel A2

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Contaminated bulk material is cleaned One of the most annoying and expensive problems with bulk material processing is the contamination by foreign substances. These contaminants not only reduce the quality of the final product, they also cause damage to the machines and failures. Especially high-strength small metal parts such as screws, nuts, washers, or cotter pins cause serious damage to the processing machinery. For this reason, the production costs with contract processing are often uncontrollable. Ebbecke has the production under control To solve this costly nuisance, the engineers of Ebbecke Verfahrenstechnik AG have developed their own system with which goods that have been contaminated by metal particles can be cleaned. This is done using the inductively-working metal detector that detects even the finest metal abrasions and reliably separates them from the goods. Through a trouble-free production process delays, non-compliance of supply contracts and consequent compensatio

Request for a quoteResults for

Metal screws - Import exportNumber of results

10 ProductsCountries

Company type