- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical engineering

Results for

Mechanical engineering - Import export

VOXELJET AG

Germany

The VX4000 is the world's biggest industrial 3D printing system for sand molds. It has a cohesive build space measuring 4,000 x 2,000 x 1,000 mm (LxWxH). This machine can be used to economically produce very large individual molds, a great many small series components or a combination of the two. With its uniquely large volume, the VX4000 maximizes productivity and flexibility. The unique and patented layering process was specially adapted for this printer. Instead of lowering the building platform during the printing process, the print head and coater are raised with each layer. As a result, the machine can bear the enormous weight of the building platform, which can be quickly exchanged via a rail—making it possible to print nearly continuously. Sand can be used as the particulate material. The VX4000's print head system can achieve a resolution of up to 300 dpi. A layer applied in one cycle is 300 µm thick.

Request for a quote

VOXELJET AG

Germany

The VX500 is a 3D printer for industrial applications that has been tried and tested many times over in practice. These machines can be found wherever there is a demand for the straightforward production of prototypes and models. Despite their compact dimensions, they captivate with the features of a high-performance printer, such as multi-jet print heads, integrated material handling and job boxes. The machine is very fast, easy to operate and permits cost-effective production of both individual parts and small series alike. Plastic can be used as the particulate material. The machine's build space measures 500 x 400 x 300 mm. The VX500's print head system can achieve a resolution of up to 600 dpi. The thickness of a layer applied in one cycle is 150 µm. In addition, the VX500 concept is resource-friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quote

VOXELJET AG

Germany

The VX2000 is a 3D printer for industrial applications. It is a particularly good choice for cost-effectively producing large-format models from sand cores for prototyping. The VX2000 can also be used to economically manufacture small-series components. The machine is fast and easy to operate. The build space measures up to 2,000 x 1,000 x 1,000 mm. The VX2000's print head system can achieve a resolution of up to 300 dpi. A layer applied in one cycle is 300 µm thick.

Request for a quote

VOXELJET AG

Germany

Our international bestseller: the VX1000 is a universal 3D printer for industrial applications. The machine is fast, easy to operate and enables you to cost-effectively produce medium-sized molds, cores and models for making prototypes. The VX1000 is also suitable for producing small series. Plastic and sand can be used as the particulate material. The piezo print head system of the VX1000 achieves a resolution of up to 600 dpi. The machine's build space measures 1,000 x 600 x 500 mm. The thickness of a layer applied in one cycle is 150 µm for plastic and 300 µm for sand. In addition, the VX1000 concept is environmentally friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quote

VOXELJET AG

Germany

The VX200 is the most compact 3D printer in the voxeljet portfolio. It weighs a mere 450 kilograms and, thanks to its dimensions of only 1,700 x 900 x 1,500 mm (LxWxH), the VX200 can be installed without problems in places where space is tight, such as research laboratories. The machine is very fast, easy to operate and permits the economical production of small prototypes and design pieces. Plastic and sand can be used as the particulate materials. The build space measures 300 x 200 x 150 mm. The VX200's print head system can achieve a resolution of up to 300 dpi. The thickness of a layer applied in one cycle is 150 µm for plastic and 300 µm for sand.

Request for a quote

IGUS® GMBH

Germany

Planetary gears for igus® stepper motors NEMA 23, 23XL & 34 Increased motor torque Increased brake holding torque 2 installation sizes Reduction gearing of 3 & 5 available Typical applications:Packaging technology, general mechanical engineering, inspection technology/ camera travel drylin® E data sheet - Gearbox for stepper motors GEA-60-..._EN.pdf Planetary gears for igus® stepper motors NEMA 23, 23XL & 34 Increased motor torque Increased brake holding torque 2 installation sizes Reduction gearing of 3 & 5 available Typical applications:Packaging technology, general mechanical engineering, inspection technology/ camera travel

Request for a quote

IGUS® GMBH

Germany

PMA cable protection systems are used wherever the mechanical protection of electrical lines and cables is needed. Highly flexible cable protection tubes are specifically suited for the additional protection of cable guides in e-chain® systems. Due to the combination of technical knowhow and the strictest international safety guidelines, PMA fulfils the worldwide requirements of industrial markets in application areas like mechanical engineering, automotive construction, fiber optics, solar systems as well as applications in the robot sector with high speeds and millions of alternate bending cycles.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Milling of complex components for automotive and mechanical engineering. Production of prototypes, test parts, small and large series according to data records, drawings, samples or specifications. Machining of cast and forged blanks. Attachment of decorative surfaces.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Special cylinders developed and manufactured according to individual customer requirements, specifications or specifications. Both as a completely custom-made special cylinder or modified inexpensively using standard elements with adjustments in form, function, mount, connection or material.

Request for a quote

BEFORT WETZLAR OD GMBH

Germany

Optics are rarely standalone components. They frequently need a casing, a carrier or even complex integration into a system. This is the exact specialty of our Mechanical Engineering department. We put our mechanical production skills in the service of optomechanical and even purely mechanical customer applications. We manufacture nonferrous metal, noncorroding machininggrade steel and plastic components and produce highprecision mechanical subassemblies as well as unmounted turned and milled parts in small and medium quantities. CNCmanufacturing of turning and milled parts CNCmanufacturing with driven tools CNCMilling machine with 3 and 5axis also in single and small series production Prototypes (max. turning diameter up to 60 mm and milled parts 500 x 400 x 100 mm)

Request for a quote

RUDOLF GUTBROD GMBH

Germany

Flexible and versatile Due to the many outstanding characteristics both in a technical and economic respect, E-CTFE – used in coatings from Gutbrod – can be used very flexibly in many fields of industry. Particularly for the semiconductor, micro-electronics, solar panel and chemical industry, the pharmaceutical sector as well as for plant and mechanical engineering, Rudolf Gutbrod GmbH offers with coatings made with E-CTFE excellent corrosion protection for working equipment used in these fields.

Request for a quote

BEFORT WETZLAR OD GMBH

Germany

Based on the longstanding experience in the field of industry optics, Befort is your optimal partner for the new development and production of customer specific optics and mechanooptic systems. Our experts will find and realize the best solution for your optical problem. Solutions may be based on a variety of technologies, such as spherical, refractive optics, but also freeform optics, micro optics, diffractiveaspheric or plastic optics. Furthermore, we integrate electronics, sensor technology, controls and image processing jointly with external partners. OUR SOLUTIONS ARE APPLIED IN A VARIETY OF MARKETS Medical technology Automotive Mechanical engineering Industrial image processing Laser technology Defense Sensor technology

Request for a quote

AIS EURELO DEUTSCHLAND GMBH

Germany

Ensuring that machinery is disconnected, reinstalled and recommissioned safely is a critical consideration for any movement of industrial assets or factory relocations. At AIS EURELO, we can include mechanical and electrical engineering services within your turnkey package. Our expert mechanical and electrical engineering team understands the different technical and compliance requirements across international locations to make sure we disconnect and reconnect your machinery safely and efficiently.

Request for a quote

ARINKO BAUTZEN GMBH

Germany

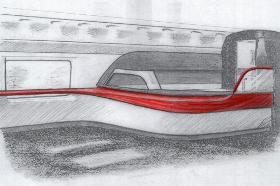

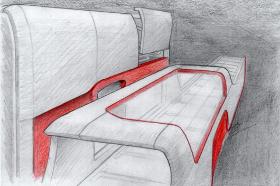

Based on multiple years of solid experience in rail vehicle construction and now also in ship construction, we offer comprehensive, engineering planning services for a variety of interior assemblies, taking into consideration various materials such as: Plastics, e.g. thermoformable materials Glass and carbon fiber reinforced plastics Solid wood and wood composite materials Glass, stone, synthetic stone (Corian) Hybrid construction of all materials in combination, as well as with stainless steel, steel, and aluminum. Our competencies in this area are governed by high customer-specific requirements and international standards. We support our customers comprehensively with preparation of the necessary documentation according to their individual requirements in the following areas: FEM verifications Weld documentation and inspection Gluing documentation Risk assessment Project documentation. Out portfolio encompasses: Partition walls

Request for a quote

ARINKO BAUTZEN GMBH

Germany

Custom sheet metal systems from the first design draft to the finished product – adapted specifically to customer requirements: In a first step, the wishes of the customer are converted using our design ideas and practical expertise into a convincing and production-ready design. The constructive implementation of the design draft, as well as all other specifications and conditions, tailored to the special technological opportunities of the respective production partner, are the focus of the second project phase. The next step of this process is the manufacture of the prototype, such as the machine housing, which is performed at the production partner's site – from the laser cutting to the finished painted assembly unit. In order to present the product in the quality you expect, our designers coordinate all interfaces on site throughout the entire process down to the final assembly to present errors and to save time.

Request for a quote

ARINKO BAUTZEN GMBH

Germany

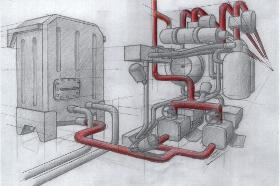

We develop application-specific solutions and products based on individual customer requirements, which fulfill complex functions and requirements: Preparation of requirements lists and specifications in cooperation with the customer Design and dimensioning Patent searches Determination and evaluation of different configurations Preparation of design drafts Constructive and drawing-based implementation Production coordination and support according to customer wishes Mock-up and prototype production Test implementation Documentation and risk assessment Our portfolio encompasses: Galleys Ready to install restroom and sanitary cabins Peripheral equipment for all sanitary and kitchen systems Stairs for stationary and mobile applications Tanks for different media and packaging space requirements Complete water treatment systems with peripheral media transfer

Request for a quote

ARINKO BAUTZEN GMBH

Germany

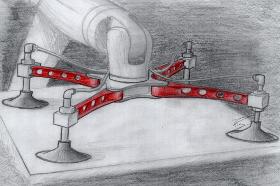

In cooperation with our system partners, we offer you various all-around solutions in the field of handling systems in plant engineering & conveyor technology. In addition to these complete solutions, we also take on the development of various plant parts and/or system components: Manipulators, grippers Transfer stations Safety equipment Workpiece carriers Control cabinets Peripheral equipment Podiums, stairs Media transfer Feeder systems Ejector systems Manual workstations Design focal points: Design & constructional drafts Use of pneumatic and/or electric drives Space-saving lifting stations Construction in accordance with relevant guidelines and regulations Static & dynamic calculation of the construction Material & weight optimization of existing and new systems Project planning to initial start-up of complete automation solutions Optimization and conversion of existing systems

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MBW GRUPPE

Germany

"The alkaline zinc-iron alloy coating is very commonly applied to steel and ferrous materials. It has been used successfully for many years in the automotive and electrical industries, in equipment and mechanical engineering and also in sheet metal processing. It is characterised by a higher resistance to environmental influences. In addition to the classic galvanising process, the zinc-iron process provides a high degree of corrosion protection paired with an attractive surface design (black, silver), as well as uniform coating thickness distribution. This is a crucial advantage for workpieces with fit sizes. This process is suitable for both barrel and rack goods."

Request for a quoteResults for

Mechanical engineering - Import exportNumber of results

19 ProductsCountries

Company type