- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- liquids

Results for

Liquids - Import export

BEFORT WETZLAR OD GMBH

Germany

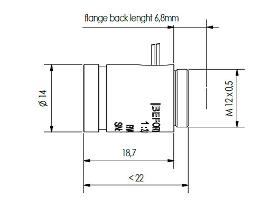

The liquid lens objective is an Smount objective with internal focusing on the basis of a liquid lens. The working distance can be electronically set by applying voltage. This procedure makes mechanical components completely obsolete. The objective’s design is compact and robust. The objective has excellent optical properties and is ideally suited for observation or image processing tasks. Focal length and mounting thread can be adjusted to customer specifications.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of liquids Tube coil heat exchangers (so-called tube cooling coil heat exchangers) are generally used to control the temperature of liquids. This system can also be used to heat or cool liquids in a controlled manner. Due to their special shape, pipe coil heat exchangers are sometimes also called hairpin heat exchangers. Inexpensive applications The simple and solid structure enables it to be used in cost-effective applications. Coiled tube evaporator systems are ideally suited for brine and glycol applications. Classic variant Coiled tube evaporator systems are a classic and proven variant in the field of heat exchanger systems. Coiled tube heat exchangers are often used in ice storage systems or in the production of cold water units. In ice storage systems, coils can be used to achieve an even build-up of ice around the coils.

Request for a quote

ANTHERMO GMBH

Germany

Heat recovery with the help of heat exchangers In industry, waste heat occurs at many points in the production process, which is often released into the environment without being used. In many cases, energy is even used to cool the waste heat flows from production so that they can be released into the environment. Heat exchangers (also called heat exchangers) are used for heat recovery so that the waste heat generated in the production process can be used again in the company. Gaseous or liquid media Waste heat can be in the form of gaseous media (e.g. warm exhaust air, steam, exhaust gases, etc.) or in the form of liquid media (e.g. hot water or other liquids). With the help of heat exchangers, the waste heat can be recovered from both gaseous and liquid media and then made available to the production process at a suitable point as energy in gaseous or liquid media. This process is known as energy recovery or also as heat recovery.

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Liquid filling Solutions, suspensions and pasty masses As part of our contract compacting we take care of contract filling of containers of any type and size for our customer and also the production of suspensions, dispensions and solutions. Through our gravimetric filling plants a semi-automatic filling is realized in Feige filling plants. Furthermore, additional modules can be used, and special solutions are also possible for special liquid filling. The filling is carried out consistently on certified scales. In addition to the technical and economic aspects, we attach great importance to complying with health and safety and environmental guidelines at our filling plants. This way overflow safety devices and drip extraction systems and of course, also gas protective covers protect both employees and the environment from harmful fumes. We also take care of the logistics Due to the high flexibility of our plants, we are able to refill a wide variety of campaign sizes at short notic

Request for a quote

PURASOL GMBH

Germany

Cleaner, solvent-based or without labelling obligation, technical and medical products, cosmetic products in different packagings, pump sprays, canisters, barrels

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

This rugged and reliable liquid ring compressor expaned the NASH Vectra compressor range with a model that operates at up to 4 bar G (60 PSIG). The XM-150 comes in 681 and 682 compliant versions and is specifically designed for the higher pressures and performance requirements found in many process applications, including vapor recovery, flare gas recovery, biogas, corrosive gas handling (e.g. VCM and chlorine) and hydrogen compression. The NASH Vectra XM-150 liquid ring compressor provides the same quality and reliability you've come to expect from the existing Vectra series with these features: Single, conical port design; Between bearing rotor/shaft design; single pressure boundary sealing point; API-681 and API-682 category II/III compliance; increased bearing life; 316 stainless steel construction; and horizontal, self-draining inlet/discharge nozzles. The rugged construction and easy to service design of this liquid ring compressor reduces maintenance requirements and minimizes downtime for maintenance and repairs in even the most demanding applications.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

15 - 140 CFM / 35 to 210 m³/h Designed from the ground up to meet the widespread needs of the process industry, the Vectra SX adds five models to Nash’s Vectra series in the 1 ½ to 10 HP range at 60 Hz (0.75 to 5.5 kW at 50 Hz), providing the right solution for small capacity vacuum pump requirements. Designed to use less energy and consume less operating liquid than competitive models, it is possible to save the user as much as 40% on power consumption and 50% on water usage.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

120 - 5300 CFM / 195 to 9,000 m³/h The NASH Vectra was designed around a modular platform using the most advanced computer aided design techniques, such as 3D solid modeling and finite element analysis (FEA). The modular platform offers the advantage of two versions with numerous common parts. The Vectra GL model, available from 120 to 830 CFM (200 to 1,500 m³/hr), is ideal for general industrial applications. It comes standard with internal mechanical seals and many Nash patented innovations including gas scavenging. The Vectra XL model was designed to meet the stringent requirements of many CPI applications. Whether operating as a vacuum pump or compressor, it features a 30 PSI (2 bar) differential capability. It is available in ductile iron or 316L stainless steel with a variety of shaft sealing options. Sizes range from 120 to 5,300 CFM (200 to 9,000 m³/hr). The NASH Vectra can be operated within a wide range of operating speeds, with numerous 50 and 60 HZ direct drive speeds. This increased turndown capability makes them ideal for varying load applications when driven by VFD's.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

1800 - 2600 CFM / 3,050 to 4,400 m³/h Found primarily in petroleum refineries and chemical plants, this rugged and reliable compressor handles highly toxic, explosive and corrosive gases in applications such as flare-gas, chlorine and Vinyl Chlorine Monomer (VCM) recovery. Together with the 14 new GARO models and other NASH liquid ring compressors, the NASH HP-9 compressor form the NASH core compressor product line, which provides compression greater than 200 psig (15 Bar abs). Low pressure compressors are available to 30 psig (3 Bar abs), and 20,000 CFM (34,000 m³/hr). As a result, NASH offers the widest pressure and capacity ranges of liquid ring compressors available worldwide.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

100 - 1800 CFM / 170 to 3,050 m³/h The GARO line of liquid ring compressors expands the capacity and pressure ranges of the Nash line to meet the ever growing requirements of our customers. Found primarily in petroleum refineries and chemical plants, these rugged and reliable compressors handle highly toxic, explosive and corrosive gases in applications such as flare-gas, chlorine and Vinyl Chlorine Monomer (VCM) recovery. The GARO line, available in single and two-stage designs, comes in: cast iron, stainless steel, carbon steel, spheroidal cast iron, 316 stainless steel, duplex stainless steel, and Hastelloy or Titanium on select models. Together with other NASH liquid ring compressors, including the HP-9, the 14 GARO models form the NASH core compressor product line, which provides compression greater than 200 psig (15 Bar abs). Low pressure compressors are available to 30 psig (3 Bar abs), and 20,000 CFM (34,000 m³/hr). As a result, NASH offers the widest pressure and capacity ranges of liquid ring compressors available worldwide.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

3000 - 16000 CFM / 5,100 to 27,200 m³/h The NASH 905 is a redesign and upgrade of the NASH 904. Capacities of the 904 pumps range upward from about 3,000 CFM at vacuum. These durable compressors can handle excess liquid carryover without any difficulty, even if it arrives as massive slugs. 904 compressors are found in many industries, including Paper, Chemical, and Mining. The 905 series has been designed to provide superior reliability and performance in harsh applications such as chemical processing or geothermal power generation. Constructed of 316L stainless steel, the 905 series offers excellent corrosion resistance and can be outfitted with a variety of mechanical seals. It also includes a patented gas scavenging feature.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Suction capacity 6,000 to 11,00 m³/h The NASH 2BQ1 590 has a unique performance range. It combines a high gas flow rate (6,000 to 11,000 m³/h) with a discharge pressure range of up to 3.75 bar abs. The standard 2BQ compressor model is equipped with a duplex steel shaft, ductile iron end shields, a massive stainless steel housing and o-rings to seal housing components. Higher quality materials are available on demand by using the modular 2BE3/4 design. The NASH 2BQ1 is certified for ATEX.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Suction capacity 125 to 1400 m³/h; Vacuum to 33 mbar abs.; Discharge pressure to 2.0 bar abs. The NASH 2BM1 magnetic drive pump series is capable of achieving volume flow rates of 125 to 1400 m³/h and vacuum of 33 mbar abs. Non-contact torque transmission is achieved by using a permanent magnetic drive system. The pump's inner working space is hermetically sealed from atmospheric conditions, eliminating any possibility of leakage. This seal is essential for demanding applications, such as processes that are required to meet the most stringent standards on environmental compatibility. ATEX applications are also possible, certifications are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

The NASH 2BE5 was developed from the proven NASH 2BE3 and 2BE4 compressors, whose reliable performance has been further improved. The development focused on optimizing performance, higher vacuum capabilities and ease of maintenance. NASH 2BE5 Benefits include: improved efficiency higher vacuum levels (to 100 mbar abs / 3" Hg abs) built-in ECO-FLO™ water saving technology with patent pending gas scavenging drop in replacement for 2BE3 and 2BE4 removable bearing brackets for easier maintenance elimination of tie rods, resulting in improved sealing due to bolted casing joints polyisoprene lining The footprint and connections to the NASH 2BE5 models are identical to its predecessors, the NASH 2BE3 and 2BE4. Therefore, exchanging or upgrading to the more efficient NASH 2BE5 requires no site modifications. The NASH 2BE5 model is available in cast iron, with stainless steel coming soon. The 2BE5 is perfect for use in mining, filter applications, paper mills, power plants, chemical plants, refineries and more.

Request for a quote

DEMAREIS GMBH

Germany

Fits with and without visual stiffeners with ND 28 thread for measuring cup with tamper evident closures. 500 ml and 1.000 ml

Request for a quoteResults for

Liquids - Import exportNumber of results

16 ProductsCountries

Company type

Category