- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding

Results for

Grinding - Import export

DRESSLER GROUP

Germany

DG Grinding processes with simultaneous cooling of the raw material to temperatures far below ambient temperature (e.g. minus 30°C); usually done with the help of liquid nitrogen, which has a temperature of around minus 196°C.

Request for a quote

DRESSLER GROUP

Germany

We grind our customers products at temperatures below room temperature.

Request for a quote

DRESSLER GROUP

Germany

Dressler Group (DG) has four brand values: flexibility, quality, innovation – and service. The last point is so important, a Dressler subsidiary bears its name: Dressler Group Customer Service. After all, the family business is renowned for its absolute customer focus. The best way to get to know Dressler Group is in person: Your contacts: Jan Dressler, CEO, COO: jan.dressler@dressler-group.com Christian Manteuffel, Team Manager Sales: manteuffel@dressler-group.com Alexander Leis, Staff Member Sales: leis@dressler-group.com

Request for a quote

DRESSLER GROUP

Germany

Fine grinding of dry products is a core competence of the Dressler Group. An extensive range of machine and system programs are available for this, offering the right solution for almost all applications. Finenesses from 1 μm (d97) and into the millimetre range can be reproduced here.

Request for a quote

SPINDEL- UND LAGERUNGSTECHNIK FRAUREUTH GMBH

Germany

can be used for the external and internal treatment of workpieces coverage of a large speed range belt-driven, or with integrated/flange-mounted motor

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AHA ALBERT HAAG GMBH METALLDRÜCKEREI - METALLWAREN

Germany

Slanting truncated cone made of stainless steel, including grinding

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

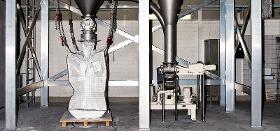

Plastic Mill The solution for the production of plastic powder Our fine grinding plants for plastic granulates enable the grinding of a wide variety of plastic granulates including even the finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. The ground goods can be processed on site or poured directly into the container specified by the customer. Technical data Target fineness: 200-1,000 µm Plant types: Disc mills, pin mills, granulators, cryogenic grinding plant Container: Bags, Big Bags, octabins, drums or drums Feeding from silo possible Filling from silo vehicles is possible Areas of application Fine grinding of LDPE Fine grinding of polypropylene Fine grinding of polystyrene Fine grinding of polyamide Fine grinding for simultaneous de-dusting of the finished product Fine grinding of EVA under cryogenic conditions

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Drug Mill The economic solution for grinding your natural products The drug mill used by us enables an economical external grinding of leaf drugs, herbs and plant roots for our customers. This way our clients save having to invest in their own, only mills that would only be fully utilized seasonally – at the same time they remain flexible with the production of teas, remedies or natural cosmetics. Technical data Throughput: 0,5-3 to/h Target fineness: 1-15 mm Product-contacting parts: Stainless steel Cleanability: Completely cleanable Grinding plant: Granulator with screen insert Feeding: Via bunker with clearing device and double shaft screw Container: Feeding as bagged goods, bales, Big Bags, octabins or in drums Areas of application Grinding of drug precursors Grinding of willow bark Grinding of St. John's wort Grinding of tea leaves Grinding of plant roots After grinding, filling in Big Bags or other containers Prospect for download

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Cryogenic Mill The solution for fine grinding temperature-sensitive products. Our cryogenic grinding plants enable fine grinding of lubricating and temperature-sensitive products. This not only results in a technically perfect grinding but in addition thermal damage of the ground material and resulting grinding losses are prevented by the cryogenic grinding. All plants are designed with swivel screw coolers and liquid nitrogen cooling, appropriate dosing devices, separators as well as bunkers as closed plants. Technical data Target fineness: 10-2,000 µm Plant types: Pin mills, cross beater mills Product-contacting parts: Stainless steel Cooling: By liquid nitrogen Delivery in: Bagged goods, Big Bags, oktabins, drums Feeding: Via feeding stations, metering screws and vertebral screw coolers Filling into: Bags, drums, Big Bags, cardboard boxes and special containers Areas of application Fine grinding of resins Fine grinding of foodstuffs Fine grinding of seeds Fine grindi

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Fine Mill The solution for fine grinding Ebbecke Verfahrenstechnik AG is your specialist for demanding tasks in the area of ??contract grinding. The fine grinding plants used enable the dissolution of agglomerates as well as the breaking up of solid grain structures including even the very finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. Accordingly, they comply with all the strict specifications and hygiene standards of the of food, pharmaceuticals and cosmetics industries. Technical data Target fineness: 1.0-5,000 µm Plant types: Classifier mills, air jet grinding plants, spiral jet grinding plants, pin mills, cross beater mills, hammer mills, Fitzmill, screen mills, disc mills, graters, crushers, cryogenic grinding, nitrogen overlaid plants Product-contacting parts: Stainless steel Delivery in: Bags, bales, Big Bags, octa

Request for a quote

STAHL OBERFLÄCHENTECHNIK GMBH

Germany

Grinding on a belt-grinding machine CNC- and robot-controlled grinding Polishing by hand or by CNC- or robot-controlled rolling machines

Request for a quoteResults for

Grinding - Import exportNumber of results

12 ProductsCountries

Company type