- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electrical drives

Results for

Electrical drives - Import export

IGUS® GMBH

Germany

- Low-maintenance system for travel up to 100 m - Other sizes and versions available, travel up to 200 m and more with E2 roller e-chains® - Protection against weather and dirt exposure - Cost-effective and fully enclosed complete solution - Standardized and modular design - Simple wall assembly or optional floor mounting - Cable lengths up to 50% shorter than festooning, low-profile installation and no cable junction - Cables are at all times guided with a defined bending radius, and tensile forces are absorbed by the e-chain® - Cables cannot hook, jam, or tear - No slip ring contacts (as is the case on motor drums) -Cables or hoses can easily be retrofitted at any time Reduce electricity costs - direct drive due to scraper, no additional drives needed (as is the case on motor drums) Scraper arm (e.g. as mechanical connection to the scraper carriage) optionally available - we document the situation on-site and will propose a customised solution

Request for a quote

ARINKO BAUTZEN GMBH

Germany

In cooperation with our system partners, we offer you various all-around solutions in the field of handling systems in plant engineering & conveyor technology. In addition to these complete solutions, we also take on the development of various plant parts and/or system components: Manipulators, grippers Transfer stations Safety equipment Workpiece carriers Control cabinets Peripheral equipment Podiums, stairs Media transfer Feeder systems Ejector systems Manual workstations Design focal points: Design & constructional drafts Use of pneumatic and/or electric drives Space-saving lifting stations Construction in accordance with relevant guidelines and regulations Static & dynamic calculation of the construction Material & weight optimization of existing and new systems Project planning to initial start-up of complete automation solutions Optimization and conversion of existing systems

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

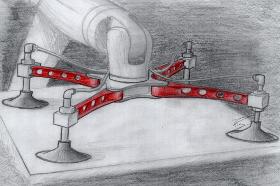

The core of this ultrasonic welding machine is the patented pneumatic HMC drive concept. It combines the benefits of pneumatics with the dynamics of an electrical drive and allows for selection of any optional start point for the weld process. The SoftTouch mode protects the sensitive joining area of the plastic parts to be welded during contact of the sonotrode.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Electrical drives - Import exportNumber of results

3 ProductsCountries

Company type