- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- custom work

Results for

Custom work - Import export

ARINKO BAUTZEN GMBH

Germany

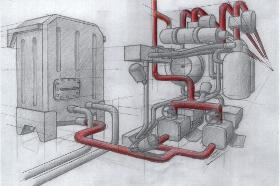

We develop application-specific solutions and products based on individual customer requirements, which fulfill complex functions and requirements: Preparation of requirements lists and specifications in cooperation with the customer Design and dimensioning Patent searches Determination and evaluation of different configurations Preparation of design drafts Constructive and drawing-based implementation Production coordination and support according to customer wishes Mock-up and prototype production Test implementation Documentation and risk assessment Our portfolio encompasses: Galleys Ready to install restroom and sanitary cabins Peripheral equipment for all sanitary and kitchen systems Stairs for stationary and mobile applications Tanks for different media and packaging space requirements Complete water treatment systems with peripheral media transfer

Request for a quote

ARINKO BAUTZEN GMBH

Germany

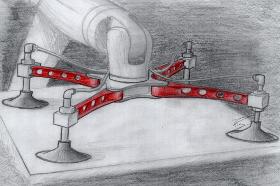

In cooperation with our system partners, we offer you various all-around solutions in the field of handling systems in plant engineering & conveyor technology. In addition to these complete solutions, we also take on the development of various plant parts and/or system components: Manipulators, grippers Transfer stations Safety equipment Workpiece carriers Control cabinets Peripheral equipment Podiums, stairs Media transfer Feeder systems Ejector systems Manual workstations Design focal points: Design & constructional drafts Use of pneumatic and/or electric drives Space-saving lifting stations Construction in accordance with relevant guidelines and regulations Static & dynamic calculation of the construction Material & weight optimization of existing and new systems Project planning to initial start-up of complete automation solutions Optimization and conversion of existing systems

Request for a quote

ARINKO BAUTZEN GMBH

Germany

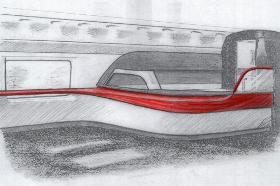

Based on multiple years of solid experience in rail vehicle construction and now also in ship construction, we offer comprehensive, engineering planning services for a variety of interior assemblies, taking into consideration various materials such as: Plastics, e.g. thermoformable materials Glass and carbon fiber reinforced plastics Solid wood and wood composite materials Glass, stone, synthetic stone (Corian) Hybrid construction of all materials in combination, as well as with stainless steel, steel, and aluminum. Our competencies in this area are governed by high customer-specific requirements and international standards. We support our customers comprehensively with preparation of the necessary documentation according to their individual requirements in the following areas: FEM verifications Weld documentation and inspection Gluing documentation Risk assessment Project documentation. Out portfolio encompasses: Partition walls

Request for a quote

ARINKO BAUTZEN GMBH

Germany

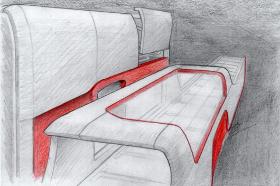

Custom sheet metal systems from the first design draft to the finished product – adapted specifically to customer requirements: In a first step, the wishes of the customer are converted using our design ideas and practical expertise into a convincing and production-ready design. The constructive implementation of the design draft, as well as all other specifications and conditions, tailored to the special technological opportunities of the respective production partner, are the focus of the second project phase. The next step of this process is the manufacture of the prototype, such as the machine housing, which is performed at the production partner's site – from the laser cutting to the finished painted assembly unit. In order to present the product in the quality you expect, our designers coordinate all interfaces on site throughout the entire process down to the final assembly to present errors and to save time.

Request for a quote

ERTEMES GMBH

Germany

With our software testing service, we help you improve the quality of your software products and identify potential bugs before they become problems for your customers. We work according to internationally recognized standards and thus offer you a high level of quality assurance. Trust in our many years of experience in the field of software development and let us help you take your products to the next level.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Compaction Custom-made solutions With our variety of granulating systems we produce granulates or compacts in every shape and size for our customers in contract work. Our modern granulating systems consist of roller compacters, pelletizing systems, drum granulators and extruders. Supplementing these are our granulating systems for vacuum packing, in addition equipped with a fully automatic compression force regulation. Through high-tech to the perfect product Our compactor plants made from stainless steel usually consist of the product feed to the roller, a vent unit by vacuuming as well as counter-rotating rollers with continuously adjustable compression force and speed regulation. Here a pre-granulation of pressed slugs, then the fine granulation of pre-granulated goods and the screening of the fine particles under continuous feedback of the screened fine grain are carried out. Our process engineers have multiple ways to customize both the shape and the properties of the final pr

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

All components pass a quality inspection before being used. Many different methods and procedures are used here (e.g. PMI 0 positive material inspection, crack detection). Our scope of machining reaches from chipping/metal cutting to sandblasting (using granule materials) to welding, assembling and painting. We handle many different metallic and nonmetallic materials as steel, stainless steel, duplex materials, titanium, plastic material We give a big importance to welding: Nash employees are certified according to ASME 9 and therefore qualified to manufacture pressure vessels and piping according to Pressure Equipment Directive (DIN EN 3834) and ASME Standards (31.3). Our systems are painted according to customer specification. We work with all wet paints and 2K paints. Anti-corrosion-coatings up to category C5M are possible. Of course, we meet all the other specifications, e.g. regarding coating thickness, as well. The electrical engineering is also done in the Nash location, from design to cabling. After the completion, the system undergoes a pressure test. Furthermore there is an option to do a complete function test to verify the performance data. Nash is certified according to ISO 9001 and ISO 14001.

Request for a quoteResults for

Custom work - Import exportNumber of results

8 ProductsCountries

Company type