- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- control lines

Results for

Control lines - Import export

RUDOLF GUTBROD GMBH

Germany

Applications High-quality fluorinated materials like ETFE, PFA and the Thermoplast PE, are used by ChemResist. ETFE and PE are also available as electrically conducting versions. ChemResist ETFE is FDA- and EU-conform. This also applies to electrically conductive specifications. Partly and fully fluorinated polymers offer universal and permanent resistance to acids, alkalis, solvents and chlorides. ChemResist possesses an extremely smooth and anti-adhesive surface and thus prevents bacterial adherence or growth. In the manufacture of highly pure products (chip industry, high purity grade chemicals) ChemResist prevents impaired quality from foreign substances or dissolved metallic ions. If special parts are to be lined, ChemResist possesses distinct advantages both from an economic as well as a qualitative point of view. The process can be adapted flexibly to the circumstances or requirements (preparation of tooling is not required). Even rigid construction specifications can...

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The innovative recuperation module from CIC acts as an energy-saving valve and control module directly in the pneumatic circuit. Functionality : It is installed directly on the consumer - e.g. on the pneumatic cylinder or in the pneumatic control circuit. The recuperation valve with its integrated control electronics measures and regulates the air consumption and feeds used compressed air back into the working cycle for reuse. Advantages : Reduction of compressed air consumption by up to 80%. Increase in efficiency of the plant. Smart monitoring and diagnostics of the pneumatic system with numerous evaluation options and control in line with Industry 4.0. Detection of leaks and irregularities. Delivery for predictive maintenance data. Avoidance of downtimes. Simple control software and wireless transfer from PC.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

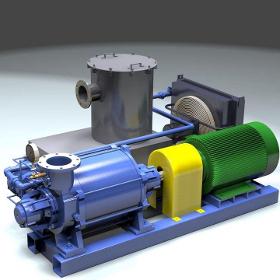

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Control lines - Import exportNumber of results

3 ProductsCountries

Company type