- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- charge electrical

Results for

Charge electrical - Import export

EPP ENERGY PEAK POWER GMBH

Germany

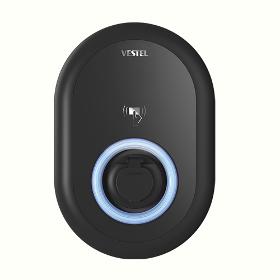

EVC04 HomePlus with a charging capacity of 11 kW - our recommendation for fast charging of most electric cars. The ADAC also recommends 11 kW wall boxes for home use. According to the new VDE guidelines, 11 kW chargers only have to be registered with the energy supplier and not approved. Guaranteed future security – thanks to numerous comfort functions and individual equipment options.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK Powder Coating enables us to create high-performance and visually appealing product surfaces with long-term corrosion protection and customized color options. Electrostatic powder coating is based on the principle of attracting parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are essential, powder coating is indispensable. These properties have led industries such as appliance manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures, and furniture manufacturing to transition significantly from wet paint to powder coating. The powder coating process is suitable for all electrically conductive and thermally stable solids. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production.

Request for a quote

SCHOCK GROUP

Germany

With SCHOCK Powder Coating, we achieve high-performance and visually appealing product surfaces with long-term corrosion protection and individual color customization. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production. Our coating facility is located at the central logistics hub of the SCHOCK Group in DE-72296 Schopfloch. This ensures our customers receive punctual, reliable, and cost-effective deliveries. Electrostatic powder coating relies on the attraction between parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are needed, powder coating is indispensable. These properties have led industries such as equipment manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures and furniture manufacturing, as well as the automotive industry to largely transition from wet paint

Request for a quote

SCHOCK GROUP

Germany

SCHOCK Powder Coating enables us to create high-performance and visually appealing product surfaces with long-term corrosion protection and customized color options. Electrostatic powder coating is based on the principle of attracting parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are essential, powder coating is indispensable. These properties have led industries such as appliance manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures, and furniture manufacturing to transition significantly from wet paint to powder coating. The powder coating process is suitable for all electrically conductive and thermally stable solids. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production.

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

Charge rollers are critical for long lasting, high quality printouts in laser printers and copiers. KB Roller Tech’s special compounds enable charge rollers to maintain continuously stable electrical properties. Primary charge rollers are mostly soft coated rollers with sensitive surfaces and precisely defined electrical properties. They are in contact with the photoconductor and transfer electrical charge in the nip area. The contact arc is created by the soft charge roller touching the hard coated photo-conductor drum. KB RollerTech`s capabilities: Length: < 354 mm Hardness: 45 - 72 Asker C Electrical properties: 1 ~ 10M Ohm (bei 500V/20°C ± 5)

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The latest generation of color laser printers have four toning stations (CMYK). Paper passes all four stations in one cycle which enables higher print speeds. This design requires precise positioning of the belt with respect to the paper during the toning cycle. This need defines the properties of a seamless belt for a perfect printout: Perfect, defect-free surface Tight tolerances of diameter, length, width and surface roughness Precisely defined electrical conductivity over the entire belt surface KB RollerTech`s capabilities: Diameters: up to 1,000 mm Width: up to 600 mm Thickness: 50 - 100 µm (±10%) Electrical properties: 1E5 - 1E16 Ohm cm Roughness: < 1,0 Ra Primary and Transfer Charge Rollers Charge rollers are critical for long lasting, high quality printouts in laser printers and copiers. KB Roller Tech’s special compounds enable charge rollers to maintain continuously stable electrical properties. Primary charge rollers are mostly soft coated rollers with sensitive surf

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Charge electrical - Import exportNumber of results

6 ProductsCountries

Company type