- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- change systems

Results for

Change systems - Import export

ERTEMES GMBH

Germany

Scalable amplifier for mobile or stationary use This compact amplifier is the ideal basis for the construction of a more complex measuring system for changing requirements. •,8 analog input channels (from +/-1uV to +/- 1000V - depending on selected signal conditioning) •,Up to 100kHz bandwidth synchronously sampled across all channels (higher bandwidths available on request) •,16/24bit resolution with 110+dB signal-to-noise ratio •,Compact dimensions (70 x 100 x 150 mm) •,Freely scalable! From an amplifier with 8 channels to multiple devices with any number of channels (e.g. 32 devices with a total of 256 channels) •,2x Ethernet interfaces, connection for external 12V power supply, LVDS connection for synchronization of several Dragonfly amplifiers (IRIG and GPS optionally available) •,Various options for connection design (depending on signal conditioning) •,Integration of further devices of the Dragonfly series to expand the range of applications

Request for a quote

FRIMO GROUP GMBH

Germany

Hydraulic presses for a broad variety of pressing, foaming, punching and forming tasks FRIMO HyPress standard machines can be adapted to fit table size, stroke, clearance, and press force requirements. Numerous options are available including safety packages, pivoting rams and tables, tool change systems, automation solutions, and complete customizations. The standard presses are designed as bolted, welded structures. The machine feet, head and sides are manufactured with high precision and fastened with fitting keys. The ram is guided via prisms and can be easily readjusted. It can alternatively be column-guided.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Shuttle table machines are characterized by an operating area that is separated from the loading station. The plastic parts to be welded can thus be optimally loaded into the equipment. Thanks to good accessibility, assembly and loading tasks can be easily performed. Can optionally be designed with one or more work stations. Approach of several operating positions is performed by means of a freely programmable linear drive. In this way, weld tasks can be divided into individual process steps. Tool change systems: optionally available.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BRITSCH SPANNZEUGE GMBH

Germany

Quick Change System Inserts for ER Cone

Request for a quote

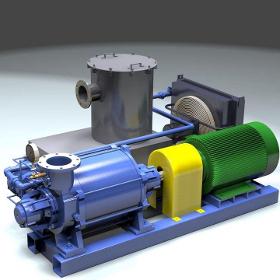

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quoteResults for

Change systems - Import exportNumber of results

8 ProductsCountries

Company type