- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air it

Results for

Air it - Import export

ANTHERMO GMBH

Germany

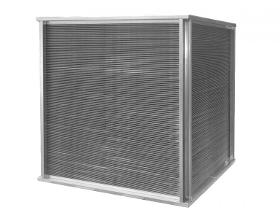

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-air heat exchanger for the industry (up to 1.000°C) Hot outgoing air and cold incoming air Very often hot exhaust gas gets out in the environment without any use. On the other hand cold incoming air must be lead into the production process and shall be warmed. This occurs for example very often within drying technology. In this case air-air heat exchangers can be used very efficient in heat recovery. As result you have great potential to save energy expenses. Three types of air-air heat exchangers The Anthermo GmbH delivers three types of different air-air-heat exchangers: cross-flow heat exchanger straight-tube heat exchanger flat-tube heat exchanger The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-air heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Thanks to their compact but stable design, the CM compact cylinders are particularly suitable for use in small spaces. Diameter range between 20 and 63 mm. Also with anti-twist device.

Request for a quote

ANTHERMO GMBH

Germany

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

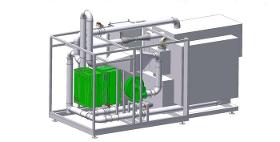

We offer you standardized complete systems for the measurement of volume & mass flows. We use measuring elements that have established themselves within previously built customer-specific test benches and convince with high measuring accuracy. The SMF® series of nozzle test benches has been specially developed for calibration with air. Critical nozzles are used as measuring elements. Up to 18 critical nozzles can be combined, depending on customer requirements. EP offers different designs for the register: Drum Design, Block Design & Register Design. Another variant is a mobile system: The EP SMF® - Mobile Flow Calibrator - a compact measuring system for flow calibration. EP Ehrler Prüftechnik manufactures single nozzles in the flow rate range from 0.005 to 2000 m³/h. In addition to our standard range, we also manufacture customer-specific nozzles that are perfectly designed for your application in compliance with DIN EN ISO 9300*.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

With the purge air method, heat recovery for balanced air mass flows can be determined for alternating, decentralised ventilation units. The uncertainties of the direct measuring method used so far due to inhomogeneous velocity and temperature profiles at the outlet of the ventilation units are circumvented by the scavenging air method and the measuring accuracy is higher. With the optional humidity conditioning the moisture recovery can also be determined. Further thermal performance indicators are the air volume flow in alternating operation and the balance, which can also be determined with the test bench. The test stand is equipped with an auxiliary fan so that continuously operating ventilation units can also be measured with the direct measuring method.

Request for a quoteResults for

Air it - Import exportNumber of results

8 ProductsCountries

Company type