- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air gas

Results for

Air gas - Import export

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

Air heat exchangers as finned tube heat exchangers Heat transfer between a gaseous media and a liquid Finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air) and a liquid (for ex. water) takes place in the air-/water heat exchangers. To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. Very often air-/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube heat exchangers can also be used as air heater, air cooler or condenser.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of gaseous and liquid media Flat tube heat exchangers are generally used as air / air or air / liquid heat exchangers. Flat tube heat exchangers are used where the (exhaust) air is polluted and the installation space is limited. In heat recovery in particular, there are numerous applications for flat tube heat exchangers as so-called exhaust gas / exhaust air heat exchangers. Little installation space and less pressure loss While the rows of tubes in smooth tube heat exchangers consist of round tubes, the rows of tubes in flat tube heat exchangers have a special profile (see illustration). This special tube profile offers advantages over the round profile in certain applications. Flat tube heat exchangers require less installation space than smooth tube heat exchangers with the same exchange area and are therefore also lighter.

Request for a quote

ANTHERMO GMBH

Germany

Temperature exchange between a gas and a liquid In the case of air-water heat exchangers (also called gas-water heat exchangers), there is a temperature exchange between a gas (usually air) and a liquid. Finned heat exchangers can cover various areas of application: - heating and evaporating, - cooling and condensing as well as heat recovery. In this context, lamellar heat exchangers are also called air heaters or air coolers. Air-water heat exchangers are often also used as exhaust gas heat exchangers or flue gas heat exchangers in order to recover the energy from warm or hot exhaust gases. Lamella packs for a large exchange area In order to achieve the largest possible exchange surface between the air and the medium (liquid) within the heat exchanger, lamellas or lamella packs are attached to the pipe system.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

We develop and manufacture Venturi tubes and nozzles as individual components or as complete VMF® systems. The VenturiMasterFlow® measuring system, VMF® for short, is used for the precise measurement of air or gas volume and mass flows 100,000 m³/h The flow measurement by means of a Venturi tube or Venturi nozzle is characterized by high measuring accuracies up to 0.5% MW and a fast response time < 10 ms. A further benefit is the high long-term stability of the measuring element.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SUVIS GMBH

Germany

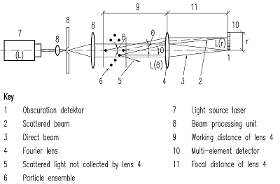

In various chemical or physical and technical processes particles of the order of 1 μm up to a few mm in size appear, whose size distribution is decisive or important for the process. There are many technical examples like in food production, pharmacy, process engineering, fuel burning in turbines, motors etc., slurry burning, and cosmetics. The laser diffraction particle sizer is capable to measure a particle size distribution from a collective of particles like a spray and to appropriately process, describe, and present it. The particle material may be solid or liquid in a gas or gas like air bubbles in a liquid. For the measurement it is only important, that the optical properties of the continuous and the dispersed phase are different. The laser diffraction particle sizer offers the advantage of a fast and non invasive measurement in a wide range of particle sizes. Especially in case of sprays or suspensions this method has become a standard measurement tool.

Request for a quoteResults for

Air gas - Import exportNumber of results

7 ProductsCountries

Company type