- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- series production

Results for

Series production - Import export

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

We are specialized in the production of precision parts and assemblies for the medical technology, automotive, telecommunications, metrology and renewable energy industries. We use our own equipment and technologies and undertake in-house fixture construction. Laser machining, electrochemical metalworking and mechanical manufacturing are our core competencies. We manufacture quantities from 50,000 up to several million per year. You will find further information in brochure at our homepage.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The valve accessories series products.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in valve accessories series products,which is made by aluminum.

Request for a quote

MBW GRUPPE

Germany

We are generally working with the double nickel-chrome process and we are able to offer the trivalent chrome plating process in series production within the mbw group. This process is suitable for rack goods

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

During re-machining, a cutting tool is used to remove material from a workpiece in order to shape or surface it as required. We offer re-machining (turning, twisting) as wage work. The following machining operations we offer: Turn thin stem, pins and tips Screw punctures, approaches and undercuts Heads of screws / cold shaped parts machining process (turning) further machining operations are possible on request. Our curve-controlled automatic Audrema lathes offer you further possibilities of finishing cold-moulded parts. These automatic lathes are designed to achieve maximum precision and reproducibility at high throughputs. Short loading and unloading times permit economical production of medium-sized and large series.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The horizontal pumping unit is suitable for emptying aqueous and fatty foodstuffs from IBC containers or tanks and is the perfect alternative to vertical drum pumps. Depending on the application, various motors are available, which you can combine with the pumping unit at any time. This gives you flexibility at all times and saves important resources. * Horizontal connection at the bottom of the container * Also for alcoholic foodstuffs, cosmetics and pharmaceutical products as well as flammable cleaning agents * Optionally with electric or compressed air drive * Low loss of medium when disconnected * Food-safe connections * Approved in accordance with ATEX Directive 2014/34/EU, category 1/2 * Approved according to FDA and Regulation (EC) 1935/2004 The value of the maximum flow rate is determined on the basis of fixed parameters and always under the same conditions. These can be found on our website.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Production of individual oil coolers according to customer requirements. Oneoff or series production with highperformance cores from Setrab in core depths of 3250mm.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Production of individual water coolers according to customer requirements. Oneoff or series production with highperformance cores in core depths of 18110mm

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

An extensive range of sophisticated diamond-cutting technologies is available, for single piece as well as for series production.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

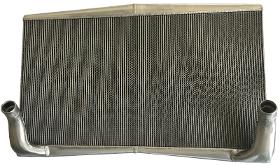

Production of individual intercoolers according to customer requirements. Oneoff or series production with highperformance cores in core depths of 28120mm. Setrab oil cooler distributor for Germany with the largest stock in the EU.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Three-axes turning technology – Our advanced, three-axes turning technology allows us to turn optics having any symmetric geometric shape. An extensive range of sophisticated diamond-cutting technologies is available, for single piece as well as for series production.

Request for a quote

A.E.T. KUNSTSTOFFE GMBH

Germany

A.E.T. is one of the few German companies that co-extrude heat-shrink tubing. In addition to the required order information, all that is required is a production sample for precise dimensions. From prototype development to high-volume series production, A.E.T. offer all quantities. An A.E.T. customer advisor will be happy to answer any further questions with you in a telephone conversation.

Request for a quote

A.E.T. KUNSTSTOFFE GMBH

Germany

"A.E.T. is one of the few German companies that co-extrude heat-shrink tubing. In addition to the required order information, all that is required is a production sample for precise dimensions. From prototype development to high-volume series production, A.E.T. offer all quantities. An A.E.T. customer advisor will be happy to answer any further questions with you in a telephone conversation. "

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Category Screw connections, adapter a. accessories / Swivel unions / Elbow 90° / Screw connections / Plain bearing / Heavy duty series / Steel Product number supplier 438623852

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We are your reliable partner for the realisation of your products - from the initial idea to series production and beyond. Our goal is to offer you a comprehensive full service and to manufacture your products economically and in the highest quality. We support you in the consultative development of your early concepts and prepare an initial cost estimate in the concept phase. In addition, we accompany you during series and mass production with our long-standing manufacturing partners in the Far East and ensure reliable logistical handling.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

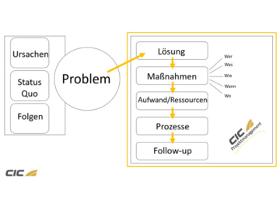

With over 20 years of experience, we know the automotive industry very well. With our team of specialists, we take on project management tasks across the entire value chain, particularly in: Technical development: from the first idea, the first components, validation, change management to series production Sourcing and Purchasing: from supplier selection, supplier evaluation, contract award, supplier qualification, tool management, prototypes, fulfillment of contracts, to trouble shooting in the event of contract disruptions Logistics: from the first capacity check, milestone plan, securing deadlines, optimizing deadlines, pre-series, series start-up, securing supplies to inventory optimization Production: from production planning, process optimization, capacity management to the continuous improvement process quality assurance

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Touchless, compact and cost-effective NOVOHALL rotary sensor for small installation spaces. Successor product for series RFA4000.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZEMO VERTRIEBS GMBH

Germany

Digital Torque Gauge with flip-up Display High precision handheld digital torque gauge with integrated LC display to measure small torque. Ideal for measurement, inspection, and tightening of precision machineries and electric devices. Flip-up display can be adjusted for optimal reading and accommodates various testing positions. BTGE(-G) series products are manufactured for the global market and offer a selection of SI, metric and American units of measurement. Equipped with SI calibration as standard. Optionally available with calibration in imperial (ozf·in, lbf·in) or in metric (kgf·cm) units. There are various application types, even for measuring rotating objects. Combined with Measurement Board (No. 809), it can be fixed to use as torque screwdriver checker, etc.

Request for a quote

BEFORT WETZLAR OD GMBH

Germany

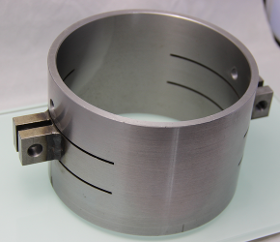

Optics are rarely standalone components. They frequently need a casing, a carrier or even complex integration into a system. This is the exact specialty of our Mechanical Engineering department. We put our mechanical production skills in the service of optomechanical and even purely mechanical customer applications. We manufacture nonferrous metal, noncorroding machininggrade steel and plastic components and produce highprecision mechanical subassemblies as well as unmounted turned and milled parts in small and medium quantities. CNCmanufacturing of turning and milled parts CNCmanufacturing with driven tools CNCMilling machine with 3 and 5axis also in single and small series production Prototypes (max. turning diameter up to 60 mm and milled parts 500 x 400 x 100 mm)

Request for a quote

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

THE BENEFITS OF TWO WORLDS Series components made of metal with complex shapes are usually very time-consuming and expensive to put into production -- but luckily there is now a superior alternative for these kinds of demanding workpieces in the form of MIM technology from Zimmer Group! The MIM process allows us to manufacture metal parts of almost any shape using an injection molding process, as easily as though it were plastic! This process lets us elegantly combine the geometrical freedom of plastic injection molding with the outstanding rigidity and wear characteristics of metals. The result is a thoroughly impressive technology for manufacturing metallic series production components with complex shapes -- and at very attractive prices, too!

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

We accompany you with our design and development from the idea to series production! We process all common thermoplastics for you. Besides polyurethane, these are mainly: PE (polyethylene), PA (polyamide), PP (polypropylene), POM, ASA, TPU, PP, TPE as well as glass fiber reinforced plastics. Advantages of the injection molding process are low unit costs with high batch sizes. Before an injection mold is ordered, we build view samples for you as laser-sintered elements or by means of 3D printing. In this way, the desired part can already be viewed without having to spend a lot of money. Our machines inject molded parts from 5 to 6000 grams.

Request for a quote

HONSEL-GROUP

Germany

The really powerful tool from HONSEL for blind rivets up to 8.0 mm diameter! With a very long stroke of 25 mm it is also eminently suitable for the setting of high-strength FERO® BOLT blind rivets. The BZ 123A is to be found in industrial series production, for example, of truck semi-trailers, and in individual vehicle and trailer construction – wherever large numbers of safety-relevant blind rivets have to be set quickly and reliably.

Request for a quote

HONSEL-GROUP

Germany

The new HONSEL battery-powered riveter is now the ultimate solution for battery-powered processing of blind rivet nuts and blind rivet studs up to M12. Designed to meet the requirements of industrial series production, Rivdom eVNG 2 offers a wide range of useful features and options. Innovative. Robust and reliable. Depending on the fastener to be processed and the application, Rivdom eVNG 2 can be operated either force-controlled or stroke-controlled via the menu on the control display. Rivdom eVNG 2 has a patented gearbox with two independently operated BLDC motors. This allows the system to be switched on and off variably during the return journey.

Request for a quote

HONSEL-GROUP

Germany

Small and light. With a weight of only 1.6 kg incl. battery, very compact dimensions and excellent ergonomics, the tool is perfectly equipped for daily use and every installation situation. Strong. 10,000 N setting force in combination with the new brushless motor makes it possible to reliably process any blind rivet up to 5.0 mm. Fast. With a pure setting process of less than one second, 30 blind rivets can be processed in 60 seconds. This means that the Rivdom eBZ 1 is twice as fast as comparable tools and saves more than 45 minutes working time per day! The ideal tool for industrial series production.

Request for a quote

SUPER-FILAMENT EINE MARKE DER ADDITIVE MATERIALS GMBH

Germany

Our advanced manufacturing crafts highly precise, custom-engineered components for technical applications in small series. Precision in 3D Construction and Modeling: Expertise in precise 3D construction and modeling underpins the production of technical production parts in small series. Leveraging advanced 3D printing, we create components meeting high standards of accuracy and functionality. Diverse Material Portfolio for Technical Applications: From classic materials (PLA, PET-G, ASA, ABS) to specialized polymers and fiber composites, our varied material portfolio caters to specific needs of technical production parts. Optimized Manufacturing for Small Series: Our techniques ensure efficient, precise production for small series, balancing cost-effectiveness and quality for swift market entry.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

In order to get started with low pressure molding technology, for prototyping new projects and producing small series, Labline offers a selection of small devices tailored to the requirements of low pressure molding technology. The basis here is the hand-held casting gun with a 0.2l tank for filling the casting materials in granulate form. In order to achieve process stability and reproducibility even with this manual processing, a timer can be connected. Two different clamping devices are available for convenient handling of sample and pre-series tools. product [hot melt application systems, hot melt coating machines for paper, hot melt, hot melt adhesive, hot melt adhesives, special machines for adhesive processing, hot melt packaging, machine for gluing, machines for gluing, hot melts, gluing machines, hot melt coating, gluing machines for labels, laboratory coating machines, systems for adhesive technology]

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

TBM flex – special deep drilling and milling centers – deep drilling and milling in one machine Modular system for drilling and milling For individual part and small series production Peeling and rolling possible Processing of forklift forks, telescopic forks, aircraft landing gear parts, special screws, special cylinders.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

Varying ambient temperatures from cold winters to summer heat, resistance against environmental influence, such as shock or vibration – these are the main requirements for agricultural technology. Before these vehicles go into series production, they are thoroughly tested in extreme conditions – day and night. In tough test applications, the CAN bus technology from MicroControl ensures reliable data transfer between vehicle components and the testing facility.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

From the Idea to Prototyping to Series Production and Evolution – MicroControl plans, develops and manufactures individual solutions. MicroControl experts will work in close liaison with the customer to realize hardware and software for the desired application. In a following step, a prototype will be developed and manufactured – either by the customer or MicroControl. In the conceptual stage, the required technical specifications of the customer’s application are checked continually.

Request for a quoteResults for

Series production - Import exportNumber of results

89 ProductsCountries

- Germany (89)

- Bonn, Düsseldorf and North Rhine and Westphalia (14)

- Frankfurt am Main and Hesse (3)

- Hamburg and region (1)

- Hannover and Lower Saxony (10)

- Kiel and Schleswig-Holstein (4)

- Leipzig and Saxony (8)

- Munich, Nuremberg and Bavaria (5)

- Schwerin and Mecklenburg-Vorpommern (6)

- Stuttgart, Freiburg and Baden-Wurtemberg (35)

- Weimar and Thuringia (3)

Category

- Woodworking - machinery and equipment (17)

- Machine tools, metal machining - parts and accessories (8)

- Folding machine tools (7)

- Hydraulics systems (6)

- Automation - systems and equipment (3)

- Cooling and lubrication pumps (3)

- Laser - cutting and welding machines (2)

- Electrical & Electronic Components (2)

- Electronic data processing - microcomputers (2)

- Mechanical engineering - custom work (2)

- Plate glass and mirrors (2)

- Surface treatment - machinery and equipment (2)

- Valves for industrial fittings (2)

- Plastics moulding (1)

- Connectors, electronic (1)

- Control panels - electric (1)

- Drilling machinery (1)

- Engines & Parts (1)

- Fittings, pipe, tube and hose - plastic (1)

- Joints, pneumatic (1)