- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- separators for liquids

Results for

Separators for liquids - Import export

SUVIS GMBH

Germany

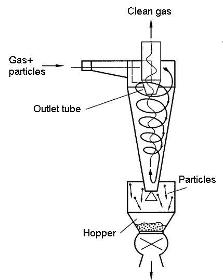

Hydro cyclone units are applied in order to separate coarse and fine solid particles from liquids . These type of separators are particularly capable of separating sand, starch, and other finely distributed materials. With hydro cyclones it is possible to separate fine particles online during the process. Hydro cyclone units are used to separate, classify, and to thicken suspensions. Also, these units are used to purify ores and minerals. Also, in fibre technique and paper industry they are applied in purification processes to separate dirt. Hydro cyclones are frequently run in parallel mode. The lay out and design of hydro cyclones are performed empirically similar to the duct cyclones. In the lower flow region of a hydro cyclone an air swirl forms during the separation process, which is not substantially influencing the cyclone flow. Because of the large dimension of the cyclone, wall friction has much more influence on the flow.

Request for a quote

RIEGLER & CO.KG

Germany

Distributors are components for separating or joining together liquids or gases. We offer various distributors, distributor strips, distributor pieces with several outputs and distributor sockets.

Request for a quote

RIEGLER & CO.KG

Germany

Distributors are components for separating or joining together liquids or gases. We offer various distributors, distributor strips, distributor pieces with several outputs and distributor sockets.

Request for a quote

RIEGLER & CO.KG

Germany

Distributors are components for separating or joining together liquids or gases. We offer various distributors, distributor strips, distributor pieces with several outputs and distributor sockets.

Request for a quote

RIEGLER & CO.KG

Germany

Distributors are components for separating or joining together liquids or gases. We offer various distributors, distributor strips, distributor pieces with several outputs and distributor sockets.

Request for a quote

SUVIS GMBH

Germany

The gas cyclone belongs to the mostly applied technical separators, because it has applicationwise some fundamental advantages. One of them is certainly the fact that its construction does not show any movable components. For the large variety of different kinds of dispersed (particulate) phases (for example dust particles, metal chips, wooden waste, liquid droplets) and different gas conditions (pressure, temperature) the lay out and computation of a cyclone is still a complex task. Suvis has specialised in the development and lay out of cyclone separators and can offer professional solutions and consulting in the area of gas cyclones. Many years of experience gained through numerous cyclone development projects results in optimal solutions for our customers. A cyclone separator applies centrifugal forces and represents an effective apparatus for separating gas, liquid or solid particles from a continuous phase in chemical, process or environmental engineering.

Request for a quote

FLOTTWEG SE

Germany

Flottweg nozzle separators (2- and 3-phase nozzle separators) are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. The product to be clarified or separated flows via a stationary inlet pipe into the inside of the bowl and is gently accelerated to operating speed by the distributor.

Request for a quote

FLOTTWEG SE

Germany

From algae harvesting to beer clarification and protein extraction: If you want to separate or purify liquids or remove ultra-fine particles you need strong and robust separators. Where decanter centrifuges reach their performance limits, the use of separators begins. Thanks to their high speeds, they are able to optimally process liquids. Clarifiers (2-phase separation), separate the finest solid particles from a liquid. As purification separators (3-phase separators), they separate liquid phases of different densities and simultaneously remove solids. Equipped with special features as the Flottweg Soft Shot® discharge system our products belong to the high qualitative products on the market.

Request for a quote

FLOTTWEG SE

Germany

In many aspects of process engineering, separators are used for mechanical separation and clarification of mixtures comprising solids and liquids. A separator is liquid-oriented and works with a higher rotation speed than a decanter. As a result, the generated centrifugal acceleration (g number) of a separator is significantly more powerful than in decanter centrifuges. Flottweg separators are suitable for separating ultrafine solid particles from a liquid (clarifier separator). Furthermore, Flottweg separators are suitable for separating mixtures of liquids with different densities at the same time as separating a solid (purifier). Flottweg AC separators (Automatic Cleaning) can be used in a wide range of applications, and are also available in various configurations. — Beverage and brewing industry — Starch industry — Chemicals and biotechnology — Extracting and processing fats and oils

Request for a quote

FLOTTWEG SE

Germany

The Flottweg AC1700 separator – the newest member of the Flottweg family Separators are used to separate the finest solid particles from liquids. Separators are available from Flottweg for a wide range of applications, from the production of beverages to the production of vegetable oil. Our separators are subject to different requirements depending on the application and size of the respective plant. To be able to offer our customers more options and the optimum solution, we have expanded our separator portfolio with a new machine size: the Flottweg AC1700 separator. The Flottweg AC1700 separator fits between our popular AC1500 and AC2000 series and completes our product portfolio for the food and beverage industry. With over 70,000 m² / 753,474 ft² of clarification area and an acceleration of 11,000 g, the compact separator ensures an optimally clarified final product with a high throughput.

Request for a quote

FLOTTWEG SE

Germany

Flottweg Sedicanter separates solids from liquids. Its special feature: the solids consist of a sediment with properties ranging between soft and fluid. Typical applications of the Sedicanter are "soft products": ► Biomass, yeast and protein suspensions. ► Fermentation broths and UF retentate ► CIP cleaning liquids and coarse matter-free live sludge ► Fruit juice byproducts and plant-derived raw materials ► Soap separation from oil refining processes The special technical features of the Flottweg Sedicanter: ► Separation of extremely difficult-to-sediment solids by acceleration up to 10,000 gee. ► Hygienic design, thus usable for applications in biotechnology ► Flexibility with fluctuating composition of the feed product by the adjustable impeller ► Gas-tight operation is possible by sealing the separation space off from the ambient air using inert gas

Request for a quote

FLOTTWEG SE

Germany

Flottweg nozzle separators (2- and 3-phase nozzle separators) are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. The product to be clarified or separated flows via a stationary inlet pipe into the inside of the bowl and is gently accelerated to operating speed by the distributor. Characteristics of our nozzle separators: — Energy-optimized and low-wear bowl design — High performance — Simple and fast maintenance — Designed for perfect hygiene The Flottweg nozzle separators are available in two basic designs: — Clarifier / 2-phase nozzle separator — Concentrator / 3-phase nozzle separator

Request for a quote

FLOTTWEG SE

Germany

Flottweg nozzle separators (2- and 3-phase nozzle separators) are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. The product to be clarified or separated flows via a stationary inlet pipe into the inside of the bowl and is gently accelerated to operating speed by the distributor. Characteristics of our nozzle separators: — Energy-optimized and low-wear bowl design — High performance — Simple and fast maintenance — Designed for perfect hygiene The Flottweg nozzle separators are available in two basic designs: — Clarifier / 2-phase nozzle separator — Concentrator / 3-phase nozzle separator

Request for a quote

FLOTTWEG SE

Germany

Disc stack centrifuges are high-speed centrifuges for the mechanical separation and clarification of mixtures comprising solids and liquids. Due to their special design, disc stack centrifuges work at a very high rotation speed. As a result, the centrifugal acceleration (g-force) generated by a disc stack centrifuge is extremely powerful. Moreover, the discs included provide a large clarifying area. Thus, it is possible to separate ultrafine solid particles from a liquid and to separate liquid mixtures in an efficient way.

Request for a quote

FLOTTWEG SE

Germany

Flottweg nozzle separators (2- and 3-phase nozzle separators) are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. The product to be clarified or separated flows via a stationary inlet pipe into the inside of the bowl and is gently accelerated to operating speed by the distributor. Characteristics of our nozzle separators: — Energy-optimized and low-wear bowl design — High performance — Simple and fast maintenance — Designed for perfect hygiene The Flottweg nozzle separators are available in two basic designs: — Clarifier / 2-phase nozzle separator — Concentrator / 3-phase nozzle separator

Request for a quote

BORSIG GMBH

Germany

Reducing energy, saving resources and safe processing have high priority in the chemical and petrochemical industry today. Our advanced liquid separation technologies are targeted to treat hydrocarbon based or solvent containing process streams and provide valuable tools for process intensification. Typically organic liquid streams are processed by conventional thermal unit operations that consume high amounts of energy, operate at high temperatures and/or require additional chemicals for efficient separation. Our membrane based solutions offer potent alternatives or additions for new processes and a valuable tool for the retrofit of existing unit operations. Our product range: - BORSIG Organic solvent nanofiltration - BORSIG Pervaporation - BORSIG Process development services

Request for a quoteFAUDI GMBH

Germany

Advantages Absolute separation of liquid particles greater than 10; for the operation under etreme temperature and pressure; minimal pressure loss Area of application For the filtration of natural gas Flow rate Various filter sizes and the modular design enable any required flow rate. classification number P51 Filter aid - Filtration degree - Medium Air, gases Filter material Wired Mesh

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MESUTRONIC GMBH

Germany

Metal separator for installation in liquid conveying lines to inspect fluid as well as pasty products like baby food. The hygienic 3-way separating valve without dead space is suitable for CIP and optional pigging cleaning procedures. Versions for aggressive products, aseptic filling or high temperatures are available on request.

Request for a quoteFAUDI GMBH

Germany

Advantages Filter aid-free separation of coolants accomplished with hydrocyclone technology. Area of application Continuous separation of suspended solids in liquids with a high demand on purity. The impurities may vary in size, shape and material. Flow rate Various filter sizes and the modular design enable any required flow rate. classification number - Filter aid without Filtration degree 30-100 µm Medium Oil and emulsion Filter material Hydrocyclone

Request for a quotePWL GMBH & CO. ANLAGENTECHNIK KG

Germany

PWL static screens provide high operational reliability in the static liquid solid separation for municipal and industrial applications particularly for the separation of fibrous and non-greasy solids. The PWL static screen is very economical and easy to use. The operation of the static screen does without an electric drive or other moving parts. In industrial sewage treatment plants the PWL static screen is known for waste water treatment. Industrial users such as paper mills, food processors, tanneries, laundries, malt houses, breweries, zoos, recycling plants and many other branches rely on the PWL static screen for product recovery and waste water treatment. The curved screen surfaces are basically removable and can be pivoted depending on the width of the static screen. A specially shaped edge at the screen guides the drainage water of the statically dewatered screenings into the discharge trough of the static sieve. Optionally, the PWL static screen can be supplied with a...

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

The externally fed TanFlow Drum Screen is characterized by its rugged and simple design, as well as by its small footprint allowing for installations with limited space. The TanFlow is employed where it is necessary to separate larger flows of liquid from solids – irrespective of industrial or municipal applications. Even oily and greasy media can be separated. Function The process or waste water reaches the sieve drum surface via the headbox. First, the liquid runs from the outside of the drum into the inside. Thus, the solids which are larger than the chosen wedgewire opening settle on the surface. Due to the continuous drum rotation they are transported to the scraper where a gentle separation of the solids is effected. The cleaned liquid flows after the separation process once again through the drum, this time from the inside to the outside (backwash) where it finally leaves the machine through an outlet pipe. Installation Examples municipal WWTPs wood...

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Application Increasing fees for sewage water make high demands on in-plant sewage treatment plants. The internally fed sieve drum CenterFlow is a product to face manifold problems, designed for liquid/solid separation in the field of process and waste water of industries or WWTPs. Function The rugged sieve drum is the core of the CenterFlow. Here, the particles are retained and carefully dewatered for further discharge. Within the inlet chamber the flowing-in medium is homogenized and the flow velocity reduced. The tangentially approached sieve surface serves to efficient fine sieving even of high hydraulic loads. Due to the drum configuration the main task can either be a fast solids discharge or a slower passage through the drum if the retained solids are to be, in addition, washed or properly dewatered. With a constant rotational speed and a low drive power this sieve drum machine is a reliable component within the equipment of a plant. The high availability and the large...

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Application An efficient and reliable fine sieving is essential not only for a comprehensive water recycling but for completely closed water circulations. For these applications, the Drum Filter MDF with mesh sizes between 25 and 2000 µm is the best choice. This filter offers a high capture rate at low operational costs during continuous operation. The choice between different cleaning media is part of the adjustment to the individual site conditions. In addition, different discharge devices and the level controlled drum rotation have to be considered. Function The Drum Filter MDF is a unit made of stainless steel, designed for liquid/solid separation within the field of process and waste water of various industries. From the Drum Filter’s inlet connection the waste water runs off into the filter drum consisting of a steel construction which is covered with a stainless steel wire gauze. The solids settle at the gauze and are transported upwards by the rotating filter drum. The...

VEHGRO B.V

Germany

"What is pea protein powder? Peas, everyone knows peas: they are small, round and green. Most people like them and some people dislike them. The best known use of peas is in pea soup. But peas are also used as the basic raw material for the production of pea protein powder. A protein powder is full of protein. Athletes use protein powders to support their muscle building. Muscles need protein to develop and recover. And one of the most widely used plant protein sources is pea protein powder. How is Pea protein powder made? After harvesting, the peas are selected, cleaned and liquefied. The protein is extracted through a double separation process: the protein liquid is decanted and then purified. It is then dried, sieved, inspected and packed for shipment. Our organic pea protein powder has a protein content of at least 80% Healthy properties Pea protein powder Pea protein powder combines all the best of peas into a long lasting and easy to use …"

Request for a quote

SUVIS GMBH

Germany

A further area of activity of Suvis is the development and application of modern numerical methods for the calculation (prediction) of flows using CFD in industry, science etc. Our employees are especially trained in view of technical applications of numerical flow simulations. Within the recent years we conducted several projects in the area of multiphase flows. We dealt with applications in the optimisation of processes in chemical engineering, the transport of particles, gas cleaning and particle separation from gases and liquids, and the calculation and optimisation of cyclone separators. We apply powerful commercial software tools like grid generators in order to generate numerical grids using CADdata in a short time for even complex applications. Also, for flow calculations and the evaluation of 3D flow fields we apply powerful software solutions. Furthermore, for certain individual problems we apply codes we have developed our selves.

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: ZA 20-67-905 Manufacturer: GEA Westfalia Separator Description: Centrifugal mixer Liquid discharge: With hermetic discharge Constructional features: Noise protected design Design of hood and sediment collector: Removable hood

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: OSE 80-0196-067 Manufacturer: GEA Westfalia Separator Description: Self-cleaning disc centrifuge Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for clarification or separation Liquid discharge: With double centripetal pump Constructional features: Standard design Design of hood and sediment collector: Hinged hood Type of drive: Flange type motor vertical

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: OSE 80-0136-067 Manufacturer: GEA Westfalia Separator Description: Self-cleaning disc centrifuge Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for clarification or separation Liquid discharge: With double centripetal pump Constructional features: Standard design Design of hood and sediment collector: Hinged hood Type of drive: Flange type motor vertical

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: ZA 80-67-905 Manufacturer: GEA Westfalia Separator Description: Centrifugal mixer Liquid discharge: With hermetic discharge Constructional features: Special design Design of hood and sediment collector: Removable hood

Request for a quoteResults for

Separators for liquids - Import exportNumber of results

61 ProductsCountries

Category

- Oiling - machines and systems (9)

- Import-export - mechanical engineering (6)

- Pneumatic systems and tools (4)

- Food industry - machinery and equipment (3)

- Threads and yarns, artificial and synthetic (3)

- Containers, metal (2)

- Gas filters (2)

- Filters, liquid (1)

- Filtering equipment and supplies (1)

- Drainage systems and equipment (1)

- Measurement and regulation equipment and instruments - output and flow (1)

- Organic food (1)