- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- semi-automatic filling machine

Results for

Semi-automatic filling machine - Import export

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

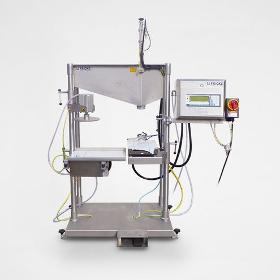

Filling station with electronic balance for precise filling of foaming liquids, for gassing products or products that load themselves statically, e.g.: cleaning and care products, solvents, chemical liquids, mineral oils, glazes. For the filling of open containers, e.g. canisters. Below level filling, coarse/precision filling valve, does not drip. Product supply via pump or gravity. The filling station has the following advantages: ■ a nearly foam free filling that can be calibrated ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ easy operation ■ the filling station needs only little space

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 42 enables complex control tasks and MES/ERP connections as well as remote maintenance. Its modular design allows it to be expanded into a fully automatic filling line with container conveying, capping and labelling. Suitable for viscous to pasty liquids such as paints, it features an electronic scale and fills open containers just above the filling level. The product is fed from storage tanks by gravity or pumps. ■ a calibratable over-level filling unit with travelling valve just above the filling level ■ Thread-cutting, non-drip filling valve ■ quick cleaning of the valve ■ Quick changeover to other container dimensions and changing products ■ The ideal solution for small and medium-sized filling orders ■ Filling, capping and palletising by one person ■ Can be used immediately: just connect energy (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

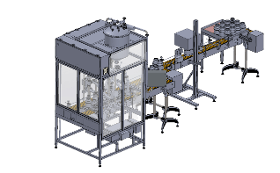

The EFS 22 offers flexible expansion options, supports complex control tasks and MES/ERP connections, and enables remote maintenance. Thanks to its modular design, it can be expanded into a fully automatic filling line with container conveying, capping and labelling. Suitable for foaming, gassing or statically charging liquids, such as cleaning agents, it offers electronic scales, automatic container transport and drip-free under-level filling. Product is fed directly from storage tanks via gravity or pumps. ■ Almost foam-free, calibratable under-level filling ■ quick cleaning of the valve ■ Quick changeover to other container dimensions and changing products ■ the ideal solution for small and medium-sized filling orders ■ simple operation ■ low space requirement ■ can be used immediately just connect energy (electricity and/or compressed air only) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 50 is a semi-automatic filling machine with over and under level valves for the precise filling of viscous to pasty liquids such as paints, varnishes or adhesives. It is suitable for over-level filling into open containers such as cans and buckets as well as for under-level filling into bunghole containers, e.g. canisters, for foaming, gassing or statically charging liquids. ■ a calibratable over-level filling system ■ Thread-cutting, non-drip filling valve ■ an almost foam-free, calibratable under-level filling system ■ quick cleaning of the valve ■ Quick changeover to other container dimensions and changing products ■ the ideal solution for small and medium-sized filling orders ■ Simple operation by one person ■ Filling capacities of up to 10 containers per minute ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

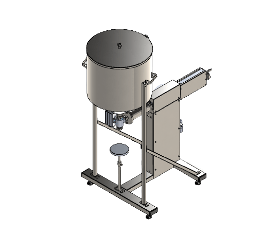

A semi-automatic filling machine with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or inks. For filling open containers, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from intermediate container positioned above the scale with bottom discharge valve using natural drop. The System offers you: ■ calibratable above level filling ■ Thread-cutting, non-dripping filling valve ■ fast cleaning of the container (container and valve are cleaned in approx. 5 min using 1 l of solvent) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 10 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic platform weigher for precise filling of low viscous liquids, e.g.: paints, varnishes, dispersions. For the filling of standard container types, e.g. open cans, buckets and canisters. Above level filling for coarse and fine flow. Product feed from intermediate container positioned above the scale with bottom discharge valve using natural drop. ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the Container (Container and valve can be cleaned in approx. 5 minutes by using 1 litre solvent) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For the filling of open containers, such canisters, open lidded drums or IBCs (Intermediate Bulk Container), directly on the pallet. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibrated above level filling of several containers on one pallet ■ thread-cutting, non-dripping filling valve ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ simple operation by one person ■ Handling of empty containers (lifting heavy loads (filled containers)) not applicable

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic balance for precise filling of non-foaming liquids, e. g. chemical liquids or mineral oils. For the filling of open containers, e.g. canisters. Below bunghole filling, coarse/precision filling valve, cut threads, does not drip. Product supply via pump or gravity. Direct connection via product hoses to the valve. The filling station has the following advantages: ■ a nearly foam free filling that can be calibrated ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ easy operation ■ the filling station needs only little space

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For the filling of open containers (min. Ø 150mm opening) just above fill level, e.g. canisters, open lidded drums or IBCs (Intermediate Bulk Container), directly on the pallet. above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above tevel filling just above the fill level with a ride-on valve of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ simple operation by one person ■ handling of empty containers (lifting heavy loads (filled containers)) not applicable ■ automatic height adjustment and automatic change of position

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for filling liquids which froth, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. The machine offers you: ■ an almost froth-free, calibratable below Level filling ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 6 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

Challenger 200B is semi automatic linear system It’s designed for filling liquid or pasty products in plastic jar With five work stations: Adding jar on conveyor manually, filling, adding covers on jar manually, sealing cover (induction seal), Exiting.

Request for a quote

BIZERBA SE & CO. KG

Germany

The professional filling system FSL-PRO M for companies where to-the-gram weighing and safe packaging even of flammable, foaming or corrosive liquids as well as gentle dosing are of importance. This semi-automatic machine reliably fills your already palletized containers. With a multi-interval scale you also achieve exact weighing results for large measuring ranges. The professional filling system FSL-PRO M is specifically designed for companies filling large quantities. Canisters, pails and drums are equally suitable. For easy handling, the containers are filled and weighed while standing on a pallet. The FSL-PRO M with optional additive tare allows filling of all containers with a uniform small interval from the first to the last container.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

A semi-automatic filling machine for liquid or semi-liquid materials suitable for filling packages of any shape and size from 100 grams to 1000 grams, with a productivity of up to 800 packages per hour, suitable for small production.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Semi-automatic filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. The filling station has the following advantages: ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 12 enables complex control tasks, MES/ERP connections and remote maintenance. Thanks to its modular design, it can be expanded into a fully automatic filling line at any time, including automatic container conveying, capping and labelling. It is suitable for viscous to pasty liquids such as paints and varnishes and offers automatic container transport options as well as an electronic scale. The station supports coarse/fine over-level filling and can be connected directly to storage tanks via inclines or pumps. The system offers you: ■ a calibratable oversize filling system ■ quick cleaning of the valve (the area in contact with the product consists of 3 parts) ■ quick changeover to other container dimensions and changing products ■ Filling, capping and palletising by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Fast filling of multiple containers on a single pallet. Filling station with electronic scale for filling liquids which foam, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. For the filling of bunghole containers, e.g. canisters, bunghole drums or IBCs directly on the pallet. Below level filling, coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. ■ an almost foam-free, calibratable below level filling of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ rapid changeover to other container sizes and changing products ■ simple operation by one person ■ handling of empty containers (lifting heavy loads (filled containers)) not applicable ■ automatic height adjustment and automatic change of position

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION compact design. made up to our German technology, to meet all the international and the European standards. One side labeling machine with coding, dating system Our machine can handle a large type of label, Bottles, and caps Types, size and shapes. SPECIFICATION Pneumatic paddle Volumetric filling system Type of metal used S.S 316 Labeling head. Pneumatic capping gun Drawer feeding caps Label coding system Mechanical weight adjustment system Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

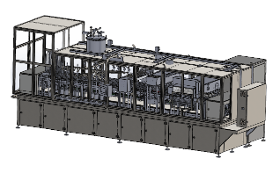

The 200A is linear filling solutions for high and fast production needs. This heavy beast is designed to fulfill heavy-duty needs for big factories and production lines up to 24,000 unit/hour. The machines can be adjusted according to the need of the customer and may serve liquid, paste and molasses in all size ranges.

Request for a quote

HERMA GMBH

Germany

HERMA 211 HC - Feeding demand for personalized medical care The wrap-around labeler 211 HC reliably processes even the smallest batches and products that tend to tip over. Ideal machine for small vials, syringes and cartridges, where the semi-automatic machine can score with its economy in frequent format changes. Labels are applied by rotating these products horizontally between two motorized rollers and the pivot peel plate with application roller. The semi-automatic labeling machine combines the high flexibility of manual product feeding with a complete equipment according to pharma specifications, including a printer for variable data and codes, and a camera for print and code verification. Optionally available with the innovative bad label return for the reliable removal of bad labels. The new 211 HC is therefore tailor-made for processing healthcare products.

Request for a quote

HERMA GMBH

Germany

Benefits of the HERMA 414 at a glance: Semi-automatic top labeling designed for a wide variety of formats on both flat and curved surfaces. For label dimensions of up to 100 mm in length and 160 mm in width. The heart of the system is the powerful HERMA 500. Entire machine is controlled by the HERMA 500’s basic drive unit. All necessary parameters can be conveniently set on the integrated operator display. Can be adjusted to different product diameters in no time at all. No control box or PLC required.

Request for a quote

HERMA GMBH

Germany

Benefits of the HERMA 211 at a glance: Semi-automatic wrap-around labeler for labeling cylindrical products. The spectrum of possible product diameters ranges from 20 to 120 mm. Fast retooling. Adjustable to different product diameters in no time at all. Heart of the system is the high-performance HERMA 500 applicator. An additional basic drive unit from the HERMA 500 is used to drive the roller prism. No control box or PLC necessary. All necessary parameters can be easily set using the integrated operator display. Aligned wrap-around labeling optionally available.

Request for a quoteResults for

Semi-automatic filling machine - Import exportNumber of results

27 ProductsCountries

Company type