- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- seals for pistons

Results for

Seals for pistons - Import export

IDG-DICHTUNGSTECHNIK GMBH

Germany

The tandem configuration of type 114 allows static pressure maintenance in the critical unpressurized range and at low pressure. The security of this function is guaranteed by use of the IDG materials U95, U96 or U99 on the low pressure or atmospheric side.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Design of the housing in the form of a groove should be avoided if possible. If this is not feasible, good housing and seal cleanability must be guaranteed. The hygienic design requirements can be met by having a particularly large groove base radius, avoiding notches and having a split housing. For WIP/WOP cleaning it is important to be able to remove and replace the seal without damaging it. Given a suitable machine design, cleaning in place is also possible.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

These sliding rings are the solution for designs which only allow room for a small or low housing. They are ideal for retrofitting into existing O‑ring grooves

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

The MANOY® U‑Cup is a pressureactivated sealing system. This means that the total sealing force is only ever as high as required to seal the prevailing pressure. This friction optimization saves energy. The MANOY® U‑Cup seals gases and liquids and also highviscosity fluids and pastes in a nonstandard version

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

The main applications are liquids at very high pressure. This seal can also be used for gases if the maximum operating parameters are restricted.

Request for a quote

SEALS-SHOP.COM - TRELLEBORG SEALING SOLUTIONS

Germany

A double-acting O-Ring energized piston seal which includes a polyurethane seal ring - suitable for dynamic applications. The Zurcon® Wynseal is a tear and abrasion resistant seal with an especially high sealing effect, aided by the special design of the seal edge profile.

Request for a quote

SEALS-SHOP.COM - TRELLEBORG SEALING SOLUTIONS

Germany

Turcon® Variseal® W2 is a single-acting seal consisting of a U-shaped jacket and a corrosion-resistant Slantcoil® spring. This spring provides an almost constant load regardless of hardware tolerances and seal wear. Suitable for reciprocating and light duty rotary movement, it is often interchangeable with an O-Ring and Back-up Ring.

Request for a quote

SEALS-SHOP.COM - TRELLEBORG SEALING SOLUTIONS

Germany

The Turcon® Variseal® M2S is a single acting seal with scraper lip, based on the design of the Variseal® M2, consisting of a U-shaped seal jacket and a corrosion resistant V-spring. The asymmetric seal profile works well even in media with high viscosity and the Turcon® material and V-spring makes it compatible with a wide variety of fluids and chemicals.

Request for a quote

SEALS-SHOP.COM - TRELLEBORG SEALING SOLUTIONS

Germany

A single-acting O-Ring energized piston seal for dynamic applications, the Turcon® Stepseal® 2K provides excellent static and dynamic sealing results. This advanced seal is stick-slip free, suits a wide range of application temperatures and demonstrates excellent abrasion and extrusion resistance. Optimum sealing characteristics are achieved by installing in a tandem arrangement.

Request for a quote

SEALS-SHOP.COM - TRELLEBORG SEALING SOLUTIONS

Germany

A double-acting O-Ring energized seal, the Turcon® AQ Seal® is suitable for sealing between two media such as fluid and gas. It consists of a Turcon® ring and an X-ring or Quad-Ring® inset into the dynamic sealing face. It has excellent sliding properties with no stick-slip effect and can be installed into small spaces.

Request for a quote

SEALS-SHOP.COM - TRELLEBORG SEALING SOLUTIONS

Germany

The double-acting Turcon® AQ Seal® 5 incorporates an elastomer Quad-Ring® and is energized by two O-Rings to improve sealing behavior. It demonstrates excellent results in applications requiring media separation, e.g fluid/fluid or fluid/gas. Works well in higher pressure applications and has a higher sliding speed compared to the AQ Seal®.

Request for a quote

SEALS-SHOP.COM - TRELLEBORG SEALING SOLUTIONS

Germany

Turcon® Glyd Ring® T is a double-acting O-Ring energized piston seal for dynamic applications, available in a range of materials (e.g. Turcon® and Zurcon®). Fully interchangeable with the earlier Glyd Ring® T, it provides very good static leak tightness and good resistance to extrusion, also demonstrating excellent friction characteristics with no stick-slip, minimal break-out force and high wear resistance

Request for a quote

BORSIG GMBH

Germany

BORSIG offers development, production and reconditioning of compressor parts, as well as their reconditioning and modification. Our product program comprises plate vales, ring valves, piston rod seals and oil scraper packings.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of valve seals, collars, O-rings, drives, piston rods and guides Lubrication of slides, slat-band and roller chains Lubrication of cutting knives as well as of needles and lifters of knitting machines Dismantling of rusted-in parts and removal of oil and greasy soiling Advantages and benefits NSF H1 registered Highly effective due to good creep properties Broad range of uses Displaces water Duolabel Clean the surfaces for optimal effect. Apply OKS 370 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system locations to be lubricated. Spray on evenly OKS 371 spray. Avoid excesses. In as far as available, observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on the basis of the service conditions. Caution: Only mix with suitable lubricants.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of valve seals, collars, O-rings, drives, piston rods and guides Lubrication of slides, slat-band and roller chains Lubrication of cutting knives as well as of needles and lifters of knitting machines Dismantling of rusted-in parts and removal of oil and greasy soiling Advantages and benefits NSF H1 registered Highly effective due to good creep properties Broad range of uses Displaces water OKS 370 is suitable for use with the OKS Airspray system Also available as spray version OKS 371 Clean the surfaces for optimal effect. Apply OKS 370 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system locations to be lubricated. Spray on evenly OKS 371 spray. Avoid excesses. In as far as available, observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on the basis of the service conditions. Caution: Only mix with suitable lubricants.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Adjustable Compression Force max. 3,500 N Stroke 15 mm Precise adjustment for any type of application: The VC model of hydraulic feed controls is ideally suited for the precise tuning of constant feed rates. The thread of the outer body of this closed hydraulic element allows simple assembly. Designs with a smooth body can also be supplied. As the hydraulic oil is forced out through the throttle opening, a constant feed rate is achieved on the stroke, which also avoids the stick-slip effect. In the models up to 55 mm stroke, the tried and tested rolling diaphragm, known from ACE shock absorbers, serves as a dynamic seal, as volume compensation of the piston rod and as a reset element.

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

Repair Kits Related Links DM Advantage Training Online Catalog QuickShip Program Literature Order Center Video Library Related Products DM Advantage Two-Speed Fan Drives PolarForce Two-Speed Conversion Kits DM Advantage Reman Fan Drives DM Advantage Repair Kits WindMaster Fans WM Revolution Fans WindShift Modular Fans To maximize DM Advantage's performance, depend on DM Advantage Repair Kits. Designed to handle the demanding high-torque, high-heat requirements of today's more powerful diesels, these parts ensure top vehicle performance, unrivaled fuel efficiency, and savings you'll see on your bottom line. DM Advantage Super Kits include a fan mounting disc, clutch pak, sheave bearing, O-rings, friction liner, air cartridge, face seal, retaining rings, facing screws and lubricant. These kits allow the rebuilding of a DM Advantage to new condition in about 30-45 minutes. DM Advantage Seal Kits include everything you need to eliminate an air leak in fifteen minutes: O-rings, retaining rings, facing screws, air cartridge, face seal and lubricant. DM Advantage Friction Disc Kits include a fan-mounting disc, friction liner and facing screws — allowing the replacement of a worn-out disc and liner in fifteen minutes. DM Advantage Friction Liner Kits include a friction liner and facing screws. Liner replacement can be completed in about fifteen minutes. All Horton Repair Kits feature Genuine Horton Parts. DM Advantage Bearing Kits include a sheave bearing, bearing nut and retaining ring. Bearing kits are designed for repairs requiring fewer parts than a super kit. DM Advantage Clutch Pack Kits include an O-ring lubricant, facing screws, air cartridge seal, spring housing/piston. Clutch Pack Kits repair the clutch pack. PolarForce Two-Speed Conversion Kits include an O-ring seal, fan mounting disc, button head screws, air chamber seal, face seal, retaining ring, friction liner, spring housing/piston, magnet assemblies. Whether you're looking to upgrade your fleet's performance or needing torque enough to turn today's 32-inch diameter fans, DM Advantage is the answer. Related Products - DM Advantage On/Off Fan Drives - DM Advantage Reman On/Off Fan Drives - DM Advantage Two-Speed Fan Drives - DM Advantage Reman Two-Speed Fan Drives - PolarForce Two-Speed Conversion Kits - WindMaster Fans - WindMaster Revolution Fans - WindShift Fans - Shogun Fans Links - DM Advantage Training - Order or View Literature - On-line Catalog

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BEULCO GMBH & CO. KG

Germany

— brackets are equipped with cross slots to guarantee an ideal adjustment of the installation set — Length compensation fittings to find the optimum position of the water meter — Screw connections with roughened external thread for even more tightness QUICKTURN piston valves — easy operation by ergonomically shaped handles — fast operation with just a few turns from "open" to "closed" — Direction of rotation indication on the handle — The label on the handle allows the clear line marking — non-rising top — Dead space top — Functional parts of the piston valve maintenance-free and permanently lubricated — Deposition-resistant sealing piston by special profile All materials meet the requirements of the Federal Environmental Agency and are approved for drinking water.

Request for a quote

HYDROSTAR MESSTECHNIK GMBH

Germany

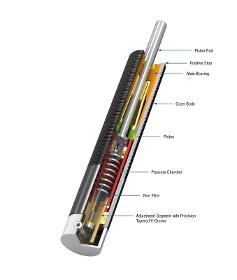

Our mechanical pressure switches are entirely “Made in Germany”. Hydrostar’s extensive and long product experience along with continuous improvements in hydraulic pressure measurements enables the production of high-quality, accurate and reliable mechanical pressure switches. These properties have proven themselves consistently worldwide. The core of the pressure switch line is the special extreme long-lasting sealing combined with the piston-springprinciple and its exceptionally accurate and reliable change-over switch. The minimum switching path with an additional throttle bore allows for a lengthy and durable life cycle. Another special feature is the potential adjustability of the pressure switch on client-side, even after the installation. Mechanical piston pressure switch for pressure monitoring Pressure range 5 to 350 bar Special Features Precise and Reliable Compact Design Change-over switch High overpressure security

Request for a quote

HYDROSTAR MESSTECHNIK GMBH

Germany

Our mechanical pressure switches are entirely “Made in Germany”. Hydrostar’s extensive and long product experience along with continuous improvements in hydraulic pressure measurements enables the production of high-quality, accurate and reliable mechanical pressure switches. These properties have proven themselves consistently worldwide. The core of the pressure switch line is the special extreme long-lasting sealing combined with the piston-springprinciple and its exceptionally accurate and reliable change-over switch. The minimum switching path with an additional throttle bore allows for a lengthy and durable life cycle. Another special feature is the potential adjustability of the pressure switch on client-side, even after the installation. Mechanical piston pressure switch for pressure monitoring Pressure range 5 to 600 bar Special Features Precise and Reliable For hard conditions Change-over switch High overpressure security

Request for a quoteResults for

Seals for pistons - Import exportNumber of results

21 ProductsCountries

Company type