- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sealing vacuum

Results for

Sealing vacuum - Import export

EK-PACK FOLIEN GMBH

Germany

MANUFACTURING PROCESS: » Cast-Coextrusion MAIN APPLICATION: » Side-sealed pouches for vacuuming and pasteurization FIELDS OF APPLICATION: » Food » Non-Food » Medical/Pharma (NBH Med) FEATURES/PROPERTIES: » Good flatness » High barrier against water vapor » High seal strength » Wide sealing range » High puncture resistance » High mechanical strength » Pasteurizable » Various tintings possible » NBH Med as a special version for medical/pharmaceutical applications

Request for a quote

EK-PACK FOLIEN GMBH

Germany

MANUFACTURING PROCESS: » Cast-Coextrusion MAIN APPLICATION: » Side-sealed pouches for vacuuming and pasteurization FIELDS OF APPLICATION: » Food » Non-Food » Medical/Pharma (NBH Med) FEATURES/PROPERTIES: » Good flatness » High barrier against water vapor » High seal strength » Wide sealing range » High puncture resistance » High mechanical strength » Pasteurizable » Various tintings possible » NBH Med as a special version for medical/pharmaceutical applications

Request for a quote

EK-PACK FOLIEN GMBH

Germany

MANUFACTURING PROCESS: » Cast-Tandem-Extrusion or » Cast-Coextrusion MAIN APPLICATION: » Side-sealed pouches for vacuum applications FIELDS OF APPLICATION: » Food » Non-Food FEATURES/PROPERTIES: » Good flatness » High barrier against water vapor » High seal strength » Wide sealing range » High puncture resistance » High mechanical strength » Various tintings possible » Also available as embossed structure

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For removing dust prior to maintenance and repair work, e.g. on magnetic plates, reading heads, audio-visual magnetic tape recording and playback heads, phonograph pick-ups, record turntables or phonograph records For cleaning vacuum sealing surfaces, sealing rings, high-voltage insulators, sample containers etc. For vacuum systems and device groups under clean-room conditions for semiconductor production Cleaning of opto-electronic reading units for bank checks and contactless cleaning of optical devices For maintenance of automated teller machines, quartz clocks or display panels For dedusting precision mechanical parts and assemblies in office machines, copiers, fax machines etc. Advantages and benefits Excellently suited for dedusting, blowing out and blowing off dust and liquids of all kinds Dry, oil-free compressed gas leaves behind no residues Replacement for ultrapure compressed air

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

SEAMIAUTOMATIC SEALING DEVICE suitable for the sealing of all sorts of plastic and glass containers. 1. foil application device PolySeal Vario DIS (left hand side) electro-pneumatic stepless pressure regulation stepless manual height adjustment with height scale foil dispensing with 2 spot pre-sealing removable pre-sealing plates heat protection shield vacuum suction nozzle roller guide with running slide foil magazine for stackable pre-cut sealing lids VARIOTRONIC, control unit for the regulation of temperature, sealing time and pressure 2. sealing device PolySeal Vario PN (right hand side) electro-pneumatic stepless pressure regulation stepless manual height adjustment with height scale sealing head heating block, swingable, anodised aluminium hollowed out sealing die heat protection shield container holder VARIOTRONIC, control unit for the regulation of temperature, sealing time and pressure

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STRONG MAGNETS GMBH

Germany

Magnetic coupling is widely used in various fields such as magnetic drive of sealing vacuum of metering pump of polyurethane foamer, magnetic drive of pneumatic ball valve, magnetic drive of stirring reactor, etc. to prevent leakage of raw gas. Magnetic coupling is mostly used in high vacuum, high cleanliness, poisonous, corrosive, or harsh environment to transfer power from the driving shaft to the driven shaft. Because of the use of isolation seal sleeve, dynamic seal into static seal, zero leakage can be achieved.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

Certain plastic encapsulated surface mount devices (SMDs), if not handled properly, can incur damage during the solder reflow attachment process to printed circuit boards (PCBs). In order to prevent damages, the moisture sensitive product is typically baked before packing. After baking, the product is placed inside a DryPack bag along with predetermined amount of desiccant and a humidity sensitive indicator card (refer to JEDEC JSTD033C). The vacuum sealed bag is labeled and placed in a pizza box carton.

Request for a quote

SEALS-SHOP.COM - TRELLEBORG SEALING SOLUTIONS

Germany

The Turcon® Variseal® HF is a single-acting axial/face sealing element comprised of a U-shaped Turcon® ring and a coiled metallic energizing spring. This design ensures gas-tight sealing even at low temperatures. It is resistant to most liquids and chemicals and has unlimited shelf life.

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Clamps directly on straight copper pipes ! Double seal construction withstands a vacuum of up to 1.3 x 101 Pa. Clamps direct on to a straight copper pipe eliminating unnecessary welding or flaring. Withstands a vacuum of up to 1.3 x 101Pa (when connected) making it possible to be used in leak testing, evacuation and refrigerant gas charge. Select from three standard types of seal materials to be used with fluids for air conditioner and refrigerator production lines. Many models to suit various pipe sizes. One lever operation simultaneously clamps and seals pipe. Double seal construction for tight fit on end and outside surface of pipe ensures excellent sealing and vacuum resistance.

Request for a quote

IBK WIESEHAHN GMBH

Germany

We supply IBK folding clamp couplings in brass, stainless steel, aluminium and PP. Our couplings have proved their worth under hard conditions in steel works and are regarded as standard. Material: - Couplings made of brass - Seals made of NBR (optionally of EPDM or Viton) - Clamp made of stainless steel Attribute: - Vacuum sealed for suction lines - No danger of icing - Interchangeable with systems of the same kind (MIL C-27450) - Suitable for closing male and female parts Temperature: - Working temperature from – 40°C to + 120°C, for higher temperature inquire suitable seal Pressure: - Max. 16 Bar working pressure –> Safety Factor 4 - Vacuum – 0,8 Bar Benefits of these couplings 1. perfect flow 2. No eddies form in the flow 3. the nozzles cannot fall out 4. the shells cannot slide about. 5. Precise fl ow control, impact-resistant, nonrusting 6. firm fit Special models on request! The dimensions stated are approximations. Subject to technical alterations

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Parylene is the short name for the polymer group of poly-para-xylylene. Parylene coatings offer a wide range of benefits. Parylene ... are fully conformal: i.e. they adapt to complex substrate contours such as sharp edges, drill holes or blind holes are pinhole-free from a film thickness of approx. 0.5 µm. are chemically insoluble and resistant to a wide range of chemicals. have very good barrier properties against moisture and chemicals. have a high dielectric strength. have dry lubricating properties (low coefficient of friction). are hydrophobic: contact angle of H2O between 92 ° and 98 °. are transparent between 90 and 96 % in the visible wavelength range (depending on type). are biocompatible: types C and N parylene can be deposited, which can be certified according to USP Class VI, ISO 10993 and FDA.

Request for a quote

MERA BELLOWS C/O ANSCHÜTZ VERWALTUNGS GMBH

Germany

Requirements to stainless steel bellows used in energy distribution (vacuum circuit breaker) systems: - Shiny, immaculate surface - Hermetic sealing for ultra-high vacuum - Exact spring rate characteristics - Long lifecycle - Consistent weld-line and possibility to weld/assembly in vacuum Sophisticated washing technologies and seamless designs allows Mera Bellows to meet these requirements for competitive pricing. Test us.

Request for a quote

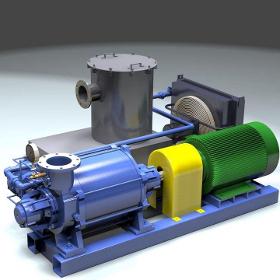

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quoteResults for

Sealing vacuum - Import exportNumber of results

14 ProductsCountries