- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotary transfer

Results for

Rotary transfer - Import export

HOCHRAINER GMBH

Germany

Different systems can achieve the objective depending on product requirements: Machine tools for type VSMH rotary transfer machining (hydraulic) Machine tool for type VSMK rotary transfer machining (cam-controlled) Type NBM finishing machines for stamped, moulded, and cold extruded parts Our years of experience in complete machining of serial parts passes to the next generation in constructive and innovative cooperation.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Forged parts made of steel, stainless steel and aluminum including mechanical processing. Pressed brass blanks including mechanical processing, also on rotary transfer machines. Sintered parts made of sintered bronze, sintered porous brass and stainless steel. Filter elements for air, liquids and fuel made of sintered ball material or mesh.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

From semi-automated to fully automated - from simple to complex: As a manufacturer of special systems, we are specialized in assembly systems to develop according to customer requirements, so that innovative products can be created. We are industry-neutral, i.e. our systems are used in the most diverse industrial sectors. We have references in automotive, medical technology, e-mobility, renewable energies and aerospace. Here you can find a selection of the implemented assembly system types: - Robot solutions - Interlinked systems - Fully automated lines - Rotary transfer machines - Manual workstations - Hybrid systems An in-house development from our company is the VARIOMODUL®, which allows your system to be quickly adapted to dynamic market changes. Standardized modules, processes, handling technology and peripherals are used. For further information please refer to the corresponding download.

Request for a quote

HONSEL-GROUP

Germany

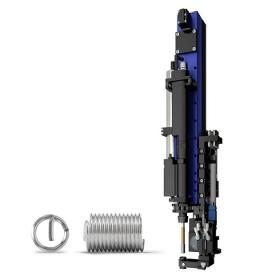

Coil screw system 2G for automated and partially automated installation of wire thread inserts. Due to the slim construction, screw systems can be placed close to each other. This leads to more efficient use of existing production areas and thus to greater economic efficiency in production. The electric linear motor is very fast at up to 3.2 m/s and enables cycle times in production to be optimized. — Screwdriver Bosch BG2 — Floating screwdriver bearings — Integrated coil transfer with rotary gripper — Linear motor — Camera

Request for a quote

RUHLAMAT GMBH

Germany

Automated solutions based on rotary transfer systems are optimum and space-saving alternatives for high quantity demands and long product life cycles. Quick - minimal workpiece changing times Space saving - the lowest space requirements Precise - accurate workpiece positioning Cheap - low investment costs with model extensions Optimal - for high quantity demands Joining / bonding O-ring assembly Dosing Wire embedding Testing / Measuring Labelling / Marking Welding Here you will find a selection of applied technologies and processes in ruhlamat specialized machines.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TAMPOPRINT GMBH

Germany

There was a need for coming up with a new pad printing machine, the basis of which opens up new target markets for us both technologically and in terms of applications. The result: the development of the SPEED 40-2 pad printing machine. Its output: as many as 9,000 cycles/h in continuous run. The production quantity is max. 18,000/h printed parts (single color with a printed image size of Ø 37 mm). Very high true-to-register printing, precision contours and photo and line images. The SPEED is a built-in execution, suitable for any kind of clocked, linear or rotary transfer systems. Thanks to its integrable misprint device there is no stopping of the machine in the absence of a workpiece. The power costs are low in comparison to the cycle number (part output). The SPEED 40-2 is a fast shortstroke machine of a new series of pad printing machines.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES built-in impact units are suitable amongst others for marking applications on transfer lines, rotary tables or testing stations. Because of the big usable stroke workpieces with different heights can be marked without any adjusting.

Request for a quoteResults for

Rotary transfer - Import exportNumber of results

8 ProductsCountries

Company type