- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rolling machines

Results for

Rolling machines - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

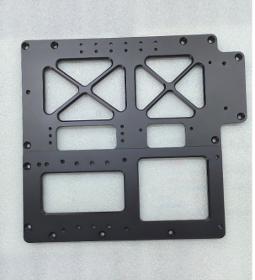

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

FÖHRENBACH GMBH

Germany

The rotary table combination RT3A100 consists of two directly driven rotary tables of the RT3A100 series. The B-axis has a swivelling range from approx. -10° to +110°; the C-axis can be rotated infinitely. The unit is driven by two integrated 3-phase synchronous motors. The drive guarantees highest dynamics and precision. An innovative clamping unit integrated in the housing guarantees high holding forces when the drives are switched off without position changes on the axes. By means of compressed are impact, the holding torque can be increased from 15Nm to 20Nm for special applications. The complete system is supplied as ready-to-connect unit.

Request for a quote

GSW SCHWABE AG

Germany

GSW Roll Feeds Precise and fast positioning with lasting performance. Built with the attributes of parallel adjustment of the top roll, highprecision roll guiding and mechanical stroke limitation for fastest cycles. In combination with most modern motion control systems our Roll Feeds feature a highly reliable production support with dynamic feeding performance of max 30 m/s² acceleration. For smaller crosssections we offer the HSseries Roll Feed model This dynamic and costeffective solution makes the upgrade from gripper feeds to the much more flexible roll feed technology affordable. from coil up to 2000 mm material width and up to 8 mm thickness max crosssection approx. 2000 x 5 mm Vmax approx. 80 200 m/min max cycles with pilot release approx. 100 220 SPM from plate or bar up to 20 mm material thickness

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

We offer our customers the leasing of our test bays for testing your machines and systems.The above-mentioned machines can also be coupled in sets of three so that even higher outputs are possible. At LDW we also have several DC machines with other speed ranges and lower outputs. We also have three-phase load machines with speed ranges from 750 to 3,000 1/min at an output range of 1,400 to 3,000 kW. Our largest measurement shaft has a torque of 5,000 Nm (accuracy class <1%). We usually verify the torque via a DC-machine. We have several DC machines with speed ranges of 100 to 6000 1/min in the test bay (depending on requirements) at an output range from 100 to 1,500 kWThe maximum torque of our largest measuring shaft is 5,000 Nm (accuracy class <1%), we usually verify the torque via a DC-machine. Depending on the specific needs we have several DC-machines with speed ranges from 100 to 6,000 rpm and outputs from 100 to 1,500 kW.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

It is increasingly important to make provisions and to keep one’s own machines in good condition. This reduces downtimes and prevents a decline in production. Our seamless diagnostics helps to ensure that machines run fault-free and enables advance planning of maintenance or repair work. The experts from LDW bring their equipment to the customer to inspect the machine on site. From partial discharge measurement through to vibration measurement – we clearly identify what technical state a machine is in. This allows downtimes to be planned ahead and ensures the efficient repair of the respective component.Diagnostics at our works in Bremen is even more effective, because we can directly consult an expert from the mechanical construction, electrical calculation or the R&D department for an assessment if necessary. The customers are provided with a comprehensive protocol after the measurements have been carried out. We then recommend the next steps for a repair or continued operation.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Machines are only as reliably available as their spare and wear parts. We therefore offer a comprehensive range of all important services. Thanks to our extensive archive, we are in a position to offer spare parts and services even for older machines from LDW, AEG and Garbe-Lahmeyer. We only need the serial number of the old motor or generator to provide or manufacture the corresponding spare parts. We are happy to assist with any question you have concerning our spare parts services, tender preparation or on-time procurement and delivery. The quality specifications we have for new parts of course also apply to our spare partsDespite the high quality of our products, the service life of some components is essentially determined by operating and environmental conditions. To avoid costly downtimes it is essential to implement preventative measures. Stocking spare parts is one example of such a sensible measure.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

The repair works are located at our site in Bremen. Through the utilisation of all the resources of our manufacturing operations our customers enjoy all the benefits of repairs, maintenance and reconditioning in accordance with the DIN IEC60034-23 standard. For work on explosion-proof machines we can provide all the certificates required for order fulfilment in full compliance with legal provisions. LDW has a certified expert and the legally binding permits ATEX, PTB KTE etc. required for a professional execution. All AEG documents from around 100 years of electrical engineering are available in their entirety within our company. This enables us to carry out repairs, supply spare parts or complete machines that are electrically and mechanically interchangeable. As part of this process we upgrade these procedures in step with the latest technological developments. The energy balance is thereby significantly improved on a regular basis.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you idler pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The carrying frame prevents belt misalignment and guarantees protection of the belt edges. As the carrying frames only function efficiently when the drum casing is clean, they are equipped and delivered with dirt repellent 60° shore soft rubber. Our carrying frames can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you drive pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Carrying rollers made of steel and HDPE Carrying rollers suitable in both heavy and light application conditions bulk goods and unit load rollers also available for delivery with cogs and conical rollers delivery of small quantities possible

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

close tolerances and longitudinally welded carrying roller tubes made of S235JR steel in accordance with DIN 2458; deep drawn steel bearing retainers with calibrated bearing seats pressed in from the side and circularly welded, material thickness min. s = 2.00 mm; RAL 3000 red powder coated sheath, coating thickness min. 60 U; 20 mm Ø round steel in accordance with ISO h9; single row radial steel ball bearings in accordance with DIN625 type 6204 with suitable grease filling and cover plates on both sides made of sheet steel C3 bearing clearance. The calculated service life of the ball bearings, assuming belt speed 2m/sec. delivery capacity 200 t/he bulk weight 0.75 t/m³ temperature range 0° C 50° C is 30,000 hours. Steel circlip in accordance with DIN 471 Sealing using double labyrinth seal, incl. suitable grease filling, galvanized, sheet steel sealing cap and plastic rain cap

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Regular rollers prevent belt misalignment and guarantee protection of the belt edges. As the regular rollers only function efficiently when the drum casing is clean, the rollers are equipped and delivered with dirt repellent 60° shore soft rubber. Our regular rollers can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

SCHMALE GMBH & CO KG

Germany

The VAP5/3P is a high quality machine for attaching hinges with fastening prongs on rolls. This machine fits the hinges to your product (case, caskets...). Benefits / Characteristics can be used with various materials (all types of wood, cardboard, certain tinplates and plastic) automatic hinge feed for rapid processing precision attachment of hinges and clasps consistent high quality ease of operation range of types of fastening possible (exterior fastening, flat lid) works with all Schmale hinge and clasp models with fastening prongs meets current machine regulations 2006/42/EU “CE“ only branded components used very maintenance friendly service and maintenance available Made in Germany Technical Data Dimensions: Length 900 mm Width 1,150 mm Height 2150 mm Weight: ca. 320 kg Noise emission: 85 dB(A) Pneumatic operating pressure: 6±0,5 bar Cylinder compacting force: 14.600 N Hinge: All Schmale hinge models with fastening prongs Hinge lengths: depending on tool (10–50 mm) Work...

Request for a quote

SCHMALE GMBH & CO KG

Germany

The VAP5/4P is a high quality machine for attaching clasps with fastening prongs on rolls. This machine attaches the clasps to your product (case, caskets…). Benefits / Characteristics can be used with various materials (all types of wood, cardboard, certain tinplates and plastic) automatic clasp feed for rapid processing precision attachment of clasps consistent high quality ease of operation range of types of fastening possible (exterior fastening, flat lid, sliding lid) works with all Schmale clasp models with fastening prongs no changeover needed on the machine for clasps in a series (up to 15 models) meets current machine regulations 2006/42/EU “CE“ only branded components used/ very maintenance friendly service and maintenance available Made in Germany Technical data Dimensions: Length 1,100 mm Width 500 mm Height 1,100 mm Weight: ca. 95 kg Noise emission: 60 dB(A) Pneumatic operating pressure: 6±0,5 bar Cylinder compacting force: 7.300 N Clasp: All Schmale clasp models...

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The gauges from the VSL Series measure the form, diameter, roundness and eccentricity of the rolls during the grinding process with very high precision. Form, radial run-out and eccentricity are measures with a precision of ± 1 µm. If an interface is available, they communicate online with the controller of the roll grinding machine and thus enable even more cost-effective use of the grinding machine. With the appropriate configuration, they measure the height and lateral alignment of the roll in the grinding machine before grinding, often enabling the set-up time to be significantly reduced. Vollmer produces the automatic roll measuring gauges for both bench-mounted machines where the roll is moved along the grinding wheel and for support machines where the grinding wheel is moved along the rotating roll. Vollmer supplies the systems for a broad spectrum of roll diameters.

Request for a quote

DSMART GMBH

Germany

Production Process of laminated printed film roll A: Artwork confirmation B: Printing cylinders making C: Prepare raw material accordingly D: Printing E: Lamination F: Slitting or folding G: Bag making/cutting H: Final inspection J: Delivery Other information of laminated printed film roll A: We are specialized in making all kinds of packaging materials, such as food bags, coffee bags, zipper bags, ziplock bags, stand up pouches, black bottom bags, aluminium foil bags, pet food bags, tobacco bags, fruit packaging bags, vegetable packaging bags, paper bags, tin boxes, hole puncher for plastic bags. B: We do printing according to your design artwork, just send us layered design in AI or PDF or PSD format. C: The MOQ is 10,000 pcs, the more the cheaper D: Similar samples are available Disclaimer: All trademarks and pictures shown here are as example of our production capability, they are not for sale, and they are the property of their owners.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HILGEFORT GMBH

Germany

Hilgefort processes steels, special steels, aluminium and copper. The machinery can be used to process sheet thicknesses ranging from 2 mm to 300 mm. The maximum dimensions for one-piece components are a diameter of up to 7 m and a length of up to 100 m. Larger assemblies are manufactured in segmented designs. This facilitates movement of unit weights up to 300 tons on the rotary devices (hydraulic lift for loading the trailer). The capacity of each of the hall cranes is around 100 tons of unit weight. The modern machinery available at Hilgefort for metal processing includes the following: Fine plasma/oxy-fuel cutter, 3.5 m x 28 m Three-roll bending machine, 3.0 m x 12 mm sheet thickness for vertical processing Four-roll bending machine, 3.0 m x 80 mm sheet thickness Four-roll bending machine, 3.0 m x 35 mm sheet thickness Three-roll bending machine, 3.0 m x 12 mm bending thickness Three-roll bending machine, 1.5 m x 5 mm bending thickness Three-roll bending machine, 1.2 m x 3 mm...

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES roll marking machines can be used to mark massive or hollow round parts. With special tools flat workpieces can also be marked. Options • Special constructions and assemblies, e.g. for brake disks or gas bottles with an automatic part handling • Customer- and workpiece-specific roll marking devices and pin fixture devices

Request for a quote

STAHL OBERFLÄCHENTECHNIK GMBH

Germany

Grinding on a belt-grinding machine CNC- and robot-controlled grinding Polishing by hand or by CNC- or robot-controlled rolling machines

Request for a quoteResults for

Rolling machines - Import exportNumber of results

21 ProductsCountries

Company type