- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- roller conveyor

Results for

Roller conveyor - Import export

TORWEGGE GMBH & CO. KG

Germany

Our solid gravity-driven roller conveyors provide an optimized solution for the internal transportation of your lightweight or heavyweight products. In order to ensure that your conveyed goods flow smoothly and independently all the way from the inlet to the outlet point, the roller conveyor must have the proper declination. This factor must be determined individually according to the type of load carrier and weight of the goods being used for your application. We can also deliver complete solutions that are individually tailored to your requirements; our support already begins during the planning phase for your project. Take advantage of our in-depth experience and benefit from our assessment of your operating conditions and influencing factors (including the suitability of using roller conveyors for your goods) – Leave nothing to chance.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you idler pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Regular rollers prevent belt misalignment and guarantee protection of the belt edges. As the regular rollers only function efficiently when the drum casing is clean, the rollers are equipped and delivered with dirt repellent 60° shore soft rubber. Our regular rollers can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The implementation of impact absorber stations provides effective protection against damage to the conveyor belt in the loading area. The belt is often pierced by sharp, large and bulky goods. Specially manufactured stations supporting impact bars absorb the impact speed. Repair and maintenance costs are thus reduced. In addition, the life expectancy of the conveyor belt and conveyor system is extended as well as the operating conditions significantly improved. Further advantages no jammed rollers causing belt misalignment absorb the drop energy, support the conveyor belt instead of the conveyor rollers in the transport area of the conveyor system and make a reliable running of the belt possible whilst ensuring the least possible friction. infinitely variable alignment to the angle of inclination by means of spindle displacement possible better material sealing due to adjustment of the material guide to within a millimetre

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

DAMBACH roller conveyors consist of a stable frame with rollers bolted in place. The rollers are driven by an easily serviced tangential chain drive with tensioning unit housed in a drive enclosure. The entire drivetrain is enclosed for safety and to prevent tampering. Flanged wheels rotate with the rollers to help transport goods carefully. The frame is height-adjustable. DAMBACH chain conveyors consist of self-supporting chain strands mounted on a rigid frame. The number of strands can be varied to suit the application. Duplex chains with straight side plates guarantee careful transport of your goods on an optimised support surface. Chains are supported on low-friction slide rails and can be individually tensioned. All chain strands are driven via a common driveshaft fully enclosed for safety. The mounting frames bolted to the main frames are height-adjustable. High throughput rates Travelling speed up to 0.5 m/s and acceleration up to 0.8 m/s² Max. 1500 kg per storage position

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestFlex Roller is excellent for handling oddshaped boxes, bags and lowgrade cartons in low to medium volume applications. Designed to expand, contract and move easily, the BestFlex Roller is a selftracking, gravity roller conveyor that has a per linear foot capacity of 220Kg per linear metre. The allsteel frame construction provides unmatched structural integrity, whether the conveyor is extended, contracted or configured in simple or compound curves. It is the best choice for moving items without a flat, solid surface. SelfTracking Cartons follow the path of the conveyor without using engineered curves. Adjustable Height Telescopic leg sections are used to raise or lower the conveyor height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. 40mm Side Plate Aluminium alloy construction features a ribbed design for added strength. Assembled with bolts and locking nuts. Castors with Brakes 127mm x 38mm Swivel Castors allow easy movement.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Flexible powered conveyors provide maximum productivity in shipping, transportation and packaging applications where usability and adaptability are most needed. With its innovative design, the PowerFlex15 powered roller conveyor requires less storage space when fully retracted and can service multiple docking doors for maximum productivity. By powering the conveyor, any package size can be moved, any distance at variable rates of speed. This powered conveyor has a capacity of 150Kg per linear metre. The PowerFlex15 also features an easy and quick way to change out the drive belts giving you added durability and less maintenance downtime. Continuous Duty Multiple Drive Motors Line speed is adjustable from 0 to 36 metres per minute. Start/stop controls at both ends. Self Tracking Cartons follow the twists and turns of the conveyor path without using engineered curves. Adjustable Height Telescopic legs to raise or lower the conveyor bed height.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With its innovative design, the PowerFlex19 powered roller conveyor requires less storage space when fully retracted and can service multiple docking doors for maximum productivity. By powering the conveyor, any package size can be moved, any distance at variable rates of speed. It is an allpower conveyor that has a capacity of 150Kg per linear metre. The PowerFlex19 features an easy and quick way to change out the drive belts giving you added durability and less maintenance downtime. Flexible power conveyors provide maximum productivity in shipping, transportation and packaging applications where usability and adaptability are needed. Continuous Duty Multiple Drive Motors Line speed is adjustable from 0 to 36 metres per minute. Start/stop controls at both ends. Self Tracking Cartons follow the twists and turns of the conveyor path without using engineered curves. Adjustable Height Telescopic legs to raise or lower the conveyor bed height. Square Tubing Legs

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

For different pipes ø: 50-108 mm - Outside ø: 70-150 mm Guide discs made of galvanized sheet steel. Example of appication: Two-piece with clamping screws. For guiding pallets on roller conveyors.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

The truck dock from Lödige facilitates the loading and unloading of air cargo units onto and off trucks. Equipped with a hydraulic lifting unit and a vertical shift function, the truck dock brings conveyor elements into line with the truck loading ramp. ULDs or pallets are transferred horizontally by a powered roller conveyor. Depending on requirements, the conveyor can be replaced or combined with other technologies such as a ball deck or castor deck. A moving version of the truck dock is also available.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

The transfer vehicle is used for transporting cargo horizontally on a single level. The individual loading units are moved on and off the racking by interconnecting the integrated roller conveyor with external roller decks. As well as transporting ULDs which take up the entire surface of the roller deck, it is possible to transfer two containers simultaneously. Flow plane: Horizontal Flow direction: Unidirectional Functions: Transporting, storing and retrieving ULDs Operating modes: Fully automated, semi-automated, maintenance Benefits: A safe way to transport ULDs with care IATA-compliant transportation of ULDs

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Pallet based automated car parking system RESPACE Pallet based technology The pallet based automated car parking system RESPACE is an interesting solution for creating up to 50 parking spaces. Drivers park their car on a pallet in a cabin. The cabin is the only interface between the driver and the car park. From this point everything is automatic. The door of the cabin closes and the car is transported downwards by lift. From there the car standing on the pallet is brought to a free parking space via roller conveyors. The pallet based parking system RESPACE is characterized by a very compact design. From the lift the pallets with the vehicles are moved directly to adjacent parking spaces. Car parking and removal follows according the puzzle principle. The car park has 60 parking spaces and is used as a hotel car parking, but also available to the public.

Request for a quote

WERNER LANGER GMBH & CO. KG

Germany

In the field of storing technology we are pleased to assist our customers with competent advice and our technical expertise / knowledge. We currently produce for example transport rails, component holders but also fully assembled brake rollers for pallet conveyors.

Request for a quote

PRESSTA EISELE GMBH

Germany

Positioning via servo motor Input of measure and quantity, push button to move carriage Display for actual value / control of measure Clamping of carriage / position control Feeding of the carriage on a steel carrier profile Integrated cable channel – accuracy ± 0,1 mm/m Manual stopper up / down Load bearing capacity 200 Kg/m, with intermediate plates and support Colour RAL 7016

Request for a quote

PRESSTA EISELE GMBH

Germany

Stopper digital display and roller conveyor Digital display, accuracy +/- 0,1 mm / m Buffer with magnetic band and sensor for exact measures Roller conveyor RD 200/3 or RD 200/4, PVC –roller distance 250mm, Load bearing capacity 200 Kg/m, with intermediate plates and support Available width 290mm oder 407mm Colour RAL 7016 Possible measuring lengths: Measuring lengths 1000 mm, total length 1300 mm Measuring lengths 2000 mm, total length 2300 mm Measuring lengths 3000 mm, total length 3300 mm Measuring lengths 4000 mm, total length 4300 mm Measuring lengths 5000 mm, total length 5300 mm Measuring lengths 6000 mm, total length 6300 mm

Request for a quote

PRESSTA EISELE GMBH

Germany

Infeed conveyor Steel or PVC roller, width 290 mm (RD200/3) or 407 mm (RD200/4), Roller distance 250 mm Load bearing capacity 200 kg/m, Colour RAL 7016 Availabe at total length of 1000 mm to 12000 mm Options: Plate in between the roller Vertical roller from PVC, height 120 mm Additional support instead of fixing angle Additional bracing to stable the conveyor

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Application Rollers are particularly well suited to the transport of light conveyed material with a smooth and stable underbody. They are used in roller strips, roller tracks, flexible roller conveyors and curved conveyors. They are used in push-through rack storage systems, as deflectors and guide tracks as well as for interlinking different conveyance systems. Load The load-bearing capabilities can be found in the table of dimensions under the “Roller” tab. The conveyance speed of Schulz rollers is up to 2 m per second.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FORBO SIEGLING GMBH

Germany

Siegling Round belts are used for conveying in the textile, wood-working, ceramic, packaging and chemical industries.Siegling Transilon round belts serve as efficient drive elements in both precision tool and machinery manufacturing. Siegling Round belts have also proven their reliability as drive elements for live roller conveyor repeatedly. Their great flexibility and elasticity make any turn possible.

Request for a quote

BIZERBA SE & CO. KG

Germany

For the formation of pre-defined package units downstream of a Bizerba labeling system The fully automatic TU 100 unit maker consists of an electrically driven, two-part package removal station with an electro-pneumatic diverter arm. It makes units according to predefined criteria, optimizing the packing process and the control of sum labels for the packages. Up to 100 packages per minute are possible. The TU 100 can be optionally fitted with a roller conveyor or a belt conveyor. (optional)

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® VIVERK are single and multi-stage spray chamber cleaning systems for aqueous cleaning, pretreatment and degreasing of tools and parts. Loading takes place via an extendable platform, which can be loaded at an ergonomic working height. The workpieces are mechanically cleaned by means of pump pressure in the spray chamber process. The temperature-controlled washing liquid is sprayed onto the workpiece via a spray frame.The washing plant is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

GMÖHLING TRANSPORTGERÄTE GMBH

Germany

Our patented solution is an indispensable part of warehouse technology and has frequently proved itself in many areas, such as in high-bay warehouses, hazardous substance warehouses, cleanrooms, quarantine warehouses and conveying systems. These bolted aluminium pallets are outstandingly easy to maintain. Damaged parts, e.g. rungs, can be rapidly and conveniently replaced using conventional tools. Their great stability makes them ideal for use on roller conveyors and in high-rack warehouses. The aluminium pallets are resistant to temperature fluctuations and can be used in all weathers. Of course, they are also suitable for use with forklift trucks, are durable and corrosion-proof and have a load capacity of up to 1000 kg per pallet. We will gladly manufacture them to the bespoke size of your choice. P 800 and P 1000 - Aluminium Pallets - screwed P 800 and P 1000 - Aluminium Pallets - welded Jack-of-all-trades - the aluminium pallet - screwed Pallet made from extremely...

Request for a quote

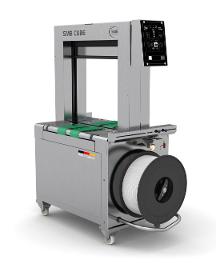

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Economical owing to highest availability Robust and extremely low maintenance Easy handling Minimum space requirement Stainless steel configuration ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 12 mm, either DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks Conveyor speed steplessly adjustable Belt type or roller conveyor Stainless steel welding plate, low maintenance GreenTech energy concept, low power consumption High-Speed-Kit, optional Intuitive operator interface MFT 'Mono-Frame-Technology' Bundle press, optional SAO 'Safe and Open' - Safe without protection doors Bundle flow control Wear-free, energy saving direct-drive-motors Low maintenance and low wear strap arch Many specific options available, easily configurable

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Extreme-temperature grease on the basis of perfluorinated polyether oils (PFPE) for use in food processing technology at maximum loads and temperatures. Grease lubrication of friction and rolling bearings in the high-temperature range Application, for example at tunnel kiln cars, baking, burn-in and drying furnaces, hot gas units, reaction vessels, boiler plants, roller and conveyor rollers in continuous furnaces, etc. Use at bearing points under influence of chemicals/fuel Advantages and benefits Maximum water and steam resistance Extraordinary resistance to chemicals, for example to solvents, for example benzene, benzol, acetone, trichloroethylene and against inorganic acids, such as sulphuric acid, hydrochloric acid and nitric acid as well as stearic acids, alcohols and halogens Excellent plastic and elastomer compatibility For long-term lubrication of lubrication points subjected to high pressure up to 300°C

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of friction and rolling bearings in the high-temperature range up to 300°C Lubrication of tunnel kiln cars, baking, burn-in and drying furnaces, hot gas units, reaction vessels, boiler plants, roller and conveyor rollers in continuous furnaces, etc. Use at bearing points under influence of chemicals Lubrication of bearings under influence of fuel Advantages and benefits Absolutely resistant to water and steam Resistant to solvents, for example benzene, benzol, acetone, trichloroethylene and against inorganic acids, for example sulphuric acid, hydrochloric acid and nitric acid as well as stearic acids, alcohols and halogens Broad range of applications above the temperature limits of other lubricating greases Excellent wear protection Reduced maintenance and lubricant costs due to possible lifetime lubrication Excellent plastic and elastomer compatibility

Request for a quote

BIZERBA SE & CO. KG

Germany

For installation in load carriers such as roller tracks and conveyors. For weight recording of different products. Depending on the type of load carrier and product one ore more load corners may be used. Load corners impress due to their robust and reliable design and ensure a low-maintenance and low-wear operation.

Request for a quote

BIZERBA SE & CO. KG

Germany

For installation in load carrier such as roller tracks and conveyors. For weight recording of different products. Depending on the type of load carrier and product one ore more weigh modules may be used. The weigh modules are impressive due to their robust and reliable design ensuring low maintenance operation and minimal wear.

Request for a quote

PRESSTA EISELE GMBH

Germany

A double head mitre saw with disappearing blades specifically studied for the tubular steel shapes. Automatic positioning of the movable unit. Electronic positioning of the cutting units on any angle within 45° and 135°. It is equipped with the system TS 690. Frontal and straight blade feed with speed adjustments. Hydro-pneumatic blade feed. Speed of rotation of the blades, variable by means of a frequency converter (inverter). Automatic shifting of the support plates of the profile once over the cutting cycle. Dynamic protection guards for a total covering of the cutting area. Blade lubrication cooling system with electric pump. Coolant liquid vat with extractable pump for vat cleaning. Cutting deepth stop device. Intermediate workpiece support automatically operating Mobile roller conveyor with pneumatic clamp for section support Compressed air treatment unit (filter/reducer/lubricator)

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Single and multi-stage spray chamber washing systems for industrial cleaning and degreasing of tools and parts. Loading takes place via an extendable loading platform at ergonomic working height. Before cleaning, the loading basket is loaded and moved into the rinsing chamber. The individual stainless steel washing nozzles can be easily maintained and adjusted according to the application. The motor-driven spraying rotor completely revolves around the loaded parts. The washing system is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

CRAEMER GMBH

Germany

The completely closed TC1 Euro pallet is the benchmark for all closed load carriers, and the ideal heavy-duty pallet for the food, pharmaceutical, and chemical industry. Thanks to its smooth surfaces, the TC1 hygiene pallet boasts excellent cleaning properties, while the cavity-free construction offers reliable protection against contamination or water ingress. Characteristics: Available with 3 runners High load-bearing capacity for heavy-duty applications Patented welding seam geometry of the top and bottom deck as well as solid wall thicknesses ensure highest impact and breakage resistance Dimensionally stable with first-class bending parameters, ideal for roller conveyors and automated high rack warehouses Excellent cleaning properties Chamfered edges on both sides of all runners Options: Corrosion-protected reinforcement profiles, for a load-bearing capacity of up to 1,750kg in high rack Rims: without, 7mm or 22mm RFID transponder

Request for a quoteResults for

Roller conveyor - Import exportNumber of results

69 ProductsCountries

Company type

Category

- Conveyor belts (12)

- Conveyor systems (8)

- Pallets (5)

- Wood veneer - machinery and equipment (5)

- Sawing machine tools (4)

- Mechanical transmission systems and components (4)

- Storage equipment and systems (4)

- Rubber products (3)

- Packing and packaging - machinery and equipment (2)

- Palletising machinery (2)

- Sandblasting equipment (2)

- Handling - Machines & Equipment (2)

- Rolling machines (2)

- Silicones (2)

- Travelators (2)

- Weight and mass - measurement and regulation instruments (2)

- Steels and metals - forming and cutting (1)

- Boring - steels and metals (1)

- Food industry - machinery and equipment (1)

- Goods handling systems, continuous (1)