- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rings- forged

Results for

Rings- forged - Import export

RINGFEDER POWER TRANSMISSION GMBH

Germany

Stainless steel series – for applications where corrosion resistance and high transmissible torque is required. This new design of Shrink Disc is made from stainless steel forged rings and uses high strength stainless steel screws. These units are available from 14mm to 195mm bore. Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Standard series – this range is the most popular, being used in most applications. This new design of Shrink Disc is made from high alloy forged rings and is practically indestructible. Replacing the smaller 4071 design, these units are available from 14mm to 195mm bore. Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances and fine...

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

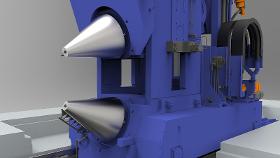

With the ring rolling mill Siempelkamp completes its range of products for the manufacture of rings. From forging the pre-forms to manufacturing the ring blanks to ring rolling, we supply everything from a single source. Siempelkamp’s ring rolling mill manufactures seamless rings made of steel and special materials such as nickel-base, titanium, or aluminium alloys using maximum radial and axial pressing forces. The radial pressing force is hydraulically generated and applied to the part via a mandrel roll. Radial rolling is carried out by reducing the roll gap between the driven external roller and the mandrel roll. The axial pressing force is also hydraulically generated and applied to the part via the upper axial roller. Axial rolling is carried out by means of the vertical forward feed of the upper axial roller. A centring device provides for the correct position of the ring during the rolling process.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Rings- forged - Import exportNumber of results

3 ProductsCountries

Company type