- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rigid foams

Results for

Rigid foams - Import export

DR. PAUL LOHMANN GMBH & CO. KGAA

Germany

Dr. Paul Lohmann® offers Potassium Acetate as powder, fine granules and granules in food/pharma/chem. pure grade. For pharmaceutical applications, it is used for parenteral nutrition. For biopharmaceutical applications, it is used as pH buffer in purification processes. For food applications, it is used as acid regulator. For industrial applications, it is used as an isomerization catalyst for the production of rigid polyurethane foams. Specific fire extinguishing agents and the modification of catalysts are further areas of application. CAS 127-08-2 EINECS 204-822-2 Dr. Paul Lohmann® carries out product and application development in close cooperation with customers. This includes the adaptation of chemical and physical parameters such as bulk density, wettability, particle size, purity or pH-value.

Request for a quote

RÜHL FEUERLÖSCHMITTEL GMBH

Germany

The key areas of application for this group of PU products are determined by their excellent insulation properties. As highly cross-linked foams (usually with closed cells), they are used in the construction industry, sanitation industry and also in the refrigeration industry. Typical properties Moulded part density of 35–120 kg/m³ Available foaming agents: pentane, hydrofluorocarbons (such as 365/227mfc) and water Special formulations and versions Good heat insulation (lambda value from 22 mW/mK) Spray systems – flame protection formulations Construction industry: DIN 4102 B2, Swiss V

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA acryl sealer is used to seal porous surfaces, such as wood, gypsum and rigid foams (not suitable for polystyrene foam). The primer dries in the air and forms a strong film. Apply a thin layer of ALWA acryl sealer evenly with a brush. If 3 % hardener powder is added, the curing process can be reduced to approx. 30 min.

Request for a quote

VKF RENZEL GMBH

Germany

The rectangular counter "Brilliant" is a high-quality, lightweight and very robust counter in straight form. The sales counter is optionally available with or without bar top and is equipped with a shelf. Due to the quality workmanship of the foldable aluminium base frame, the trade fair counter is particularly characterised by high stability, quick assembly and a large advertising space. The panels made of 3 mm PVC rigid foam are excellent for labelling and easy to install and remove. Furthermore, the promotion counter is completely foldable and comes with a transport bag.

Request for a quote

PANEL SELL GMBH

Germany

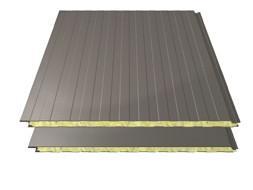

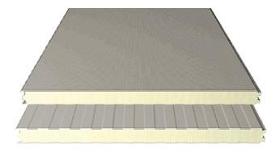

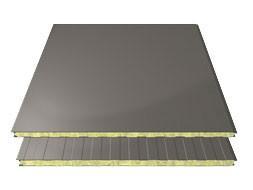

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

RÜHL FEUERLÖSCHMITTEL GMBH

Germany

Surfaces with high reproduction accuracy combined with a cellular core to reduce the weight of moulded parts are among the outstanding characteristics of the rigid integral foam product group. In combination with duromer systems, our products in this field feature an extensive range of useful characteristics. Application examples include housing components and covers. Typical properties Moulded part density of 220–900 kg/m³ Shore D hardness of 35–85 Available foaming agents: usually water, but also pentane and hydrofluorocarbons Special formulations and versions Good heat insulation Self-parting formulations possible Good coating and lamination properties Flame protection formulations Electrical industry: UL 94 V0 Construction industry: DIN 4102 B2 Rail vehicle construction: DIN 5510 (S4, SR2, ST2)

Request for a quote

RÜHL FEUERLÖSCHMITTEL GMBH

Germany

This group of polyurethane products typically features a lightweight foam core with a compact, dense skin – the so-called integral skin. Thanks to these properties, PU soft- / semi-rigid integral skin foams cover a broad range of applications such as steering wheels, shifter knobs, arm rests, protective pads, floor mats and operating room rests. Typical properties Moulded part density of 220–600 kg/m³ Shore A hardness of 10–90 Available foaming agents: pentane, hydrofluorocarbons (such as 365/227mfc) and water Good abrasion resistance Special formulations and versions Viscoelastic Anti-static Flame protection formulations Automotive: FMVSS 302 Rail vehicle construction: DIN 5510 (S4, SR2, ST2), EU TL 45545 Aircraft construction: ABD 0031, FAR 25.853 Construction industry: DIN 4102 B2 Recreation industry: M2, UNI 9175/87 (= CSE 4/83): class 1.IM, BS 5852 crib 5

Request for a quoteResults for

Rigid foams - Import exportNumber of results

10 ProductsCountries