- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- returns

Results for

Returns - Import export

ACTIVE ANTS

Germany

Returned items are inspected, restored to their original condition and re-stocked. Our returns process meets the strict guidelines of platforms like Zalando and Amazon. If you also sell through these platforms, this is extremely convenient.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

nickel plated brass*non-return valve

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

nickel plated brass*non-return valve*female connexion to*water tap Ø outside

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The STRATE non-return valve RKS is particularly suitable in areas where the prevention of flap impacts is of particular importance. In this application case the extension of the standard butterfly valve RSK by the additional component STRATE spring load (RSK-FT or RSK-FTU) is required Product features (STRATE RSK) Wide flap to prevent piercing, especially at high pressure levels Type RSK-FT: Equipped with exterior spring load to more quickly close the flap and avoid flap impact Type RSK-UD: Bypass line with pressure shock damping valve to reduce/avoid pressure shocks Type FTUD: a combination of the above types to optimally protect the pumps in case of a power outage, etc.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Due to their special design, 100 % free passage and low flow resistance, STRATE AWASTOP non-return valves are ideal for: Sewage technology, media with solids and coarse solids, sludge (up to 5 % TM) Fresh and service water technology, including in areas where high pressure losses make powerful pumps necessary On request: pumping of fluids deviating from the media listed Areas where quiet operation is particularly important Non-return valves are recognised all over the world as for universal applications in the pumping of fresh water, effluent, sludge and air. Stand for high operational safety Stand out thanks to their excellent value-for-money and low maintenance requirements 100 % free passage Low flow resistance Quiet operation thanks to the inclined valve seat which shortens the closing distance Minimum clogging tendency through optimum hydraulic design− Fail-safe closing of the valve since the closing element is fixed securely into the valve cover

Request for a quote

BÜRKLE GMBH

Germany

Retaining valve with embossed directional arrow or printed in black. With conical nozzles. Various uses.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

With the newly developed FAPI-SWITCH series, we have succeeded in designing deflection pulleys in a lightweight system design with an unprecedented smoothness and smoothness of running that set new standards in the belt grinding process. Due to the flexibility, also with regard to different dimensions, belt elephant machines of all brands can be equipped with these deflection rollers. We would be pleased to advise you on which return pulleys can be used in your processing, in order to achieve top process results.

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

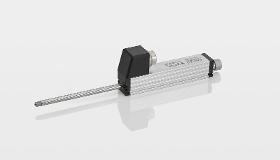

Potentiometric position transducer in compact design with one-sided actuating rod and return spring; long life span and high adjustement speed; Flexible mounting via clamps, bushing mount or flange plates; probe tip with pressed-in hardened metal ball

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Absolut transducer with integrated signal processing. Designed for direct position measurement of fixed objects or contour scanning of moving objects by roller head. Replaceable without new calibration.

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Absolute transducer in compact profile design with double-sided supported actuating rod and internal return spring; NOVOPAD non-contacting, inductive measuring principle, Teach-in function with status LEDs, probe tip with pressed-in hardened metal ball, long life span

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The special lightweight aluminium design and silicone inserts of STRATE sandwich non-return valves SB makes them ideal for: Conveying air and gases up to temperatures of 200 °C Working pressures up to 4 bar Special applications with other valve insert materials on request

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Potentiometric position transducer in compact profile design with double-sided supported actuating rod and internal return spring; very high repeatability and adjustement speed; probe tip with pressed-in hardened metal ball, long life span

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF RFS Carbon Steel Return Line Filters are designed as tank top or in-line filters. They are mounted directly on the tank top and if 100% of the system oil is filtered, they provide the optimum removal of contaminants from the system. This provides the pump with clean oil thus reducing contaminant generated wear. The filter bowl is designed with a connection, threaded or flanged, for extending the return oil beneath the surface thus preventing the entrainment of air. A high efficiency of contaminant removal is assured by using STAUFF RE Replacement Filter Elements. The high dirt-hold capacity of STAUFF Filter Elements ensures a long service life and as a result reduced maintenance costs. Valve (available as an option) ▪ Bypass valve Clogging Indicator (available as an option) ▪ Visual clogging indicator or electrical clogging switch Filter Elements ▪ Filter elements of RE series Construction ▪ Tank top or in-line mounting Operating Pressure ▪ Max. 25 bar / 365 PSI Nominal...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF RFB Return Line Filters are designed as tank top filters. They are mounted directly on the tank top and if 100% of the system oil is filtered they provide the optimum removal of contaminant from the system. This provides the pump with clean oil thus reducing contaminant generated wear. Because of it’s low weight and compact design, the STAUFF RFB Filters are ideally suited for mobile hydraulic applications. A high efficiency of contaminant removal is assured by using STAUFF RE Replacement Filter Elements. The high dirt-hold capacity of STAUFF Filter Elements ensures a long service life and as a result reduced maintenance costs. Valve (available as an option) ▪ Bypass valve Clogging Indicator (available as an option) ▪ Visual clogging indicator or electrical clogging switch Air Filter Element (available as an option) ▪ Filter paper micron rating 10 µm, other filter materials and micron ratings on request Filter Bowl with Threaded Connection (available as an option) Filter...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Return Line Filters RF are designed as tank top filters. They are mounted directly on the tank top and when 100% of the system's oil is filtered they provide the optimum removal of contamination from the system. This provides the pump with clean oil thus reducing contaminant generated wear. The filter bowl is designed to return the oil beneath the surface thus preventing the entrainment of air by the returning oil. A high efficiency of contaminant removal is assured by using STAUFF RE series Replacement Filter Elements. The high dirt-hold capacity of STAUFF Filter Elements ensures a long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass valve Clogging Indicator ( available as an option ) ▪ Visual clogging indicator or electrical clogging switch Leakage Oil Connection ( available as an option ) Filter Bowl with Threaded Connection ( available as an option ) Filter Elements ▪ Filter elements of RE series Construction ▪ Return...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF RFA Return Line Filters are a one piece design and can be used as a tank top or an in-line filter. They are mounted in the return line and if 100% of the system oil is filtered, provide the optimum removal of contaminant for the systems. This provides the pump with clean oil, thus reducing contaminant generated wear. A high efficiency of contaminant removal is assured by using STAUFF RE Replacement Filter Elements. The high dirt-hold capacity of STAUFF Elements ensures a long service life and as a result reduced maintenance costs. Valve (available as an option) ▪ Bypass valve Clogging Indicator (available as an option) ▪ Visual clogging indicator or electrical clogging switch Leakage Oil Connection (available as an option) Filter Bowl with Threaded Connection (available as an option) Filter Elements ▪ Filter elements of RE series Construction ▪ Tank top or in-line mounting Operating Pressure ▪ Max. 25 bar / 265 PSI Nominal Flow Rate ▪ Max. 110 l/min / 30 US...

Request for a quote

KITO ARMATUREN GMBH

Germany

Application as inline armature with venting or breather valve function for vessels. Preferably used for installation in pipes. Depending on the installation, the valve can be used as pressure or vacuum valve. It can also be used as non-return safety device or overflow valve.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

Non-Return Valves WITT non-return valves protect plants, pipelines and outlet points against reverse gas flow and meet all relevant standards and regulations. The product range of non-return valves includes a large choice of nominal sizes (up to DN200) and flow rates (0.35 – 106 SCFH). The sophisticated valve technology of WITT non-return valves provides small pressure drops making them also suitable for applications with smallest opening pressures. A high-quality sealing system with elastomeres prevents leakages, and dirt filters at the inlet point assure long service life of the non-return valves. Some non-return valve models can also be used as flashback arrestors. All non-return valves can be mounted in any orientation, are available with all connections, in brass and stainless steel and are suitable for almost all technical gases.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

Non-Return Valves WITT non-return valves protect plants, pipelines and outlet points against reverse gas flow and meet all relevant standards and regulations. The product range of non-return valves includes a large choice of nominal sizes (up to DN200) and flow rates (0.35 – 106 SCFH). The sophisticated valve technology of WITT non-return valves provides small pressure drops making them also suitable for applications with smallest opening pressures. A high-quality sealing system with elastomeres prevents leakages, and dirt filters at the inlet point assure long service life of the non-return valves. Some non-return valve models can also be used as flashback arrestors. All non-return valves can be mounted in any orientation, are available with all connections, in brass and stainless steel and are suitable for almost all technical gases.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Regular rollers prevent belt misalignment and guarantee protection of the belt edges. As the regular rollers only function efficiently when the drum casing is clean, the rollers are equipped and delivered with dirt repellent 60° shore soft rubber. Our regular rollers can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Check Valve with flanged connection and with a EPDM coated ball. Face to face EN 558-1 R48 Connection Flange DN50 … DN150, PN16 drilled, DN200 … DN300, PN10 drilled. Flanges acc. to EN 1092-1 DN65 – PN16 will be delivered in 4-hole execution! Mounting position Horizontal, cap above and vertical Pressure range PN10 … PN16, see data sheet Temperatur range 0°C … +80°C Media Non aggressive liquids Material Body: GGG-50, FBE-coated Cap: GGG-50, FBE-coated Ball: Metal, EPDM-coated Seals: EPDM The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice!

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Check Valve with threaded connection and with a EPDM coated ball. Connection Thread ¼” … 3″, acc.to ISO 228-1 Mounting position Horizontal, cap above and vertical Pressure range PN10 … PN16, see data sheet Temperatur range 0°C … +80°C Media Non aggressive liquids Material Body: GGG-50, FBE-coated Cap: GGG-50, FBE-coated Ball: Metal, EPDM-coated Seals: EPDM The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice!

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Dual plate check valves to be mounted between tow flanges according to EN 1092-1 Type 11 form B – PN10/PN16. Face to face EN 558-1 row 16 Connection DN50 … DN300 Mounting position Pay attention to the flow direction. Preferably mounting into a horizontal runing pipeline. Make sure to install a minimum of 5 x nominal diameter of straight pipeline in front of and behind the dual plate check valve. Do not install the valves directly onto a pump flange. Pressure range PN10 … PN16, see table Temperatur range 0°C … +80°C Media Non aggressive liquids Material Body: GGG-50, FBE-coated Flap: Stainless steel 1.4408 Stem and spring: Stainless steel 1.4401 Seals: EPDM The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice!

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Dual plate check valves to be mounted between tow flanges according to EN 1092-1 Type 11 form B – PN10/PN16. Face to face EN 558-1 row 16 Connection DN50 … DN300 Mounting position Pay attention to the flow direction. Preferably mounting into a horizontal runing pipeline. Make sure to install a minimum of 5 x nominal diameter of straight pipeline in front of and behind the dual plate check valve. Do not install the valves directly onto a pump flange. Pressure range PN10 … PN16, see data sheet Temperatur range 0°C … +80°C Media Non aggressive liquids Material Body: GGG-50, FBE-coated Flap: Steel, nickle plated Stem and spring: Stainless steel 1.4301 Seals: EPDM The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice!

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Refer to the advices on page 8! Body Stainless steel 1.4408 Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4401 (316) Stem Stainless steel 1.4404 (316) Function Pneumatic single acting with spring return, normally closed (NC). Pressure discharge One-sided Pilot pressure 6bar Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the table Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 Installation Only with vertical upwards actuator The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Refer to the advices on page 8! Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (304) Stem Stainless steel 1.4305 (304) Function Pneumatic single acting with spring return, normally closed (NC). Pressure discharge One-sided Pilot pressure 6bar Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the data sheet Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 Installation Only with vertical upwards actuator The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quoteResults for

Returns - Import exportNumber of results

35 ProductsCountries

Company type

Category

- Valves for industrial fittings (3)

- Water - production and distribution (3)

- Bearings - ball, needle and roller (2)

- Pumps (2)

- Bottles and jars, plastic (1)

- Fittings, pipe, tube and hose - plastic (1)

- Palletising machinery (1)

- Pump-driven power stations, installations and equipment (1)

- Rolling machines (1)

- Spare parts for diesel engines (1)

- Warehouse logistics (1)

- Wheels, castors and rollers (1)