- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- reins

Results for

Reins - Import export

STARRAG GMBH

Germany

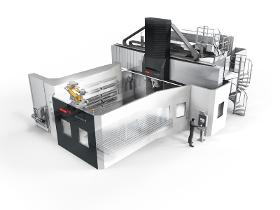

Gantry design For machining of largest and heaviest workpieces Droop+Rein offers a floor guided gantry machine line. Best accessibility and utilisation of floor space for largest workpieces combined with highest flexibility in size and configuration. Cross rail, moveable (GS) or fixed (GFS) Economic machining of largest components – flexible, dynamic and precise Floor space savings compared to table moving machines In line with the modular principle – various controls, table configurations, milling head/spindles and tool changer configurations

Request for a quote

STARRAG GMBH

Germany

How can large, heavyduty and bulky workpieces be processed without adversely affecting the weight and size of the machining result? The Droop+Rein G/GF series has been specifically developed to tackle this difficult task. The gantry machines reliably prevent dynamic losses through the table and workpiece. The G/GF series has many technical highlights to meet the requirements of complex machining tasks, such as the hydrostatic guide in all linear axes or the thermosymmetrical design of the spool milling unit with an integrated Caxis. Milling heads can be changed automatically via a head change interface. Droop+Rein has developed over 300 different milling heads for a variety of applications such as machining large diesel engines. The option to set up in a second working area during the machining time allows increased productivity.

Request for a quote

STARRAG GMBH

Germany

With the T/TF series, Droop+Rein offers gantry machining centres for heavyduty machining in many sectors Applications range from tool and mould making, aircraft component manufacturing and engine manufacturing to general mechanical engineering. Based on the robust, highly accurate and powerful basic machines, the T/TF series offers an extensive system of innovative automation and expansion stages that enable the machines to be adapted flexibly to each machining task. The optional automatically changing forktype milling head makes complex and demanding machining possible. Through extensive application knowhow, a variety of different milling heads are available including vertical milling heads, angle milling heads, and forktype milling heads for positional or simultaneously controlled applications.

Request for a quote

STARRAG GMBH

Germany

In order to produce heavy workpieces with limited available space, Droop+Rein combined the FOGS and TF machine types which are already established on the market into a new machine concept. With the FOGS HD, Droop+Rein offers a machining centre for heavyduty machining, which features high quality and precision at the same time. The constant dynamic dimensions of the Droop+Rein FOGS HD enables the user to use the machine for unmanned finishing e.g. at night or at the weekend. The Droop+Rein FOGS HD is designed for large components, as the traverse paths show (Xaxis 3,000 to 31,000 mm; Yaxis 3,000 to 6,000 mm; Zaxis 1,500 to 2,500 mm). It covers all machining operations within typical toolmaking. The FOGS HD is an efficient (50 to 100 kW (S1 operation)), precise machining highgantry machine with fast and dynamical axes and extreme high torque (2,400 to 7,500 Nm).

Request for a quote

STARRAG GMBH

Germany

With the FOGS NEO series, Droop+Rein has developed a powerful machine concept for complex machining. The range of services covers processes from machining standard geometries and prefinishing contours to final finishing. For dynamic machining with the highest feed rates, the concept caters for the movement and acceleration of constant masses, regardless of workpiece size and weight. Dynamic and flexible With its new, highly flexible and fast Caxis (±400°), the Droop+Rein FOGS NEO highspeed machining centre is ideal for the complete multifunctional machining of very large workpieces. Of course, the series also features automatic pallet or tool change, tool diameter and length measurement and automatic billing of contour deviations. Thanks to a variety of components and peripheral devices from their modular system, Droop+Rein can create an efficient and processoriented overall system that is tailored to the customer.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DORTEX MBH

Germany

When designing your event wristband, you can give free rein to your creativity. Whether your own design, unusual colors, detailed motifs or imprinted consecutive numbers – everything is possible starting from order quantities of one. The individually printed fabric wristbands live up to the highest of demands. They are made from high-quality double-faced satin and are lightfast, wear-proof, washable up to 60°C and extremely durable. The attached safety closure prevents the passing on of the festival wristbands. Due to the imprinted consecutive numbers, the entry wristband can also be used as a security solution for your event (on request). With an individually designed wristband every guest will feel like a VIP regardless of whether for a concert, festival, wedding or a birthday party.

Request for a quoteResults for

Reins - Import exportNumber of results

7 ProductsCompany type