- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- quick clamping systems

Results for

Quick clamping systems - Import export

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

SHORTENED CHANGEOVER PROCESS In modern production processes, factors such as efficiency and flexibility play an increasingly important role. For injection moulding companies, this demand for flexibility means there is a constant challenge posed by increasingly smaller lot sizes, the desire to achieve lower inventories and just-in-time deliveries.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring discs of the FAPI-FIT150 series are the ideal tool for deburring on automatic deburring machines and are particularly suitable for machining larger series. Various deburring machines are equipped with right- and left-rotating deburring discs. For this purpose we offer you our FAPI-QUICK-FIT ADAPTER! The combination of the quick-clamping system and our FAPI-QUICK-FIT ADAPTER also enables simple mounting and positioning of the deburring discs FAPI-FIT150 on the deburring machine. We will be pleased to advise you which fill variant is best suited for your application.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

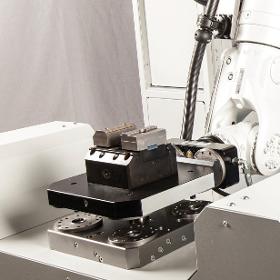

You are short of personnel, but have to process your orders, preferably 24/7? Then the DockLock AC zero-point clamping system for automated fixture change-over, in either the hydraulic or pneumatic version, is perfect for you. The clamping device quick change-over system for stationary applications allows automated change-over of your clamping devices in two minutes. And with repeatability of ≤ 0.005 mm, without alignment. The design of the form fit clamping and power transmission is identical to the DockLock for manual set-up. In addition, it is equipped with a closure at the clamping position as protection against contamination and chips. That ensures even less wear and reduces maintenance expenses. In addition, standard features include an air sensing control, air-blast support isles and a piston position control for a safe and reliable automated process.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Are you tired of losing so much time due to change-over on your machining center? Then we have something for you. The DockLock zero-point clamping system in the hydraulic or pneumatic version. One clamping device quick change-over system for stationary applications. It allows you to change your clamping devices in two minutes. And with repeatability of ≤0.005 mm, without alignment. A special feature: form fit clamping with a collet or clamping segments. That means a rigid clamping set-up and higher repeatability. This also prevents clamping marks on the clamping bolt as opposed to zero-point clamping systems with balls or sliders, which lead to inaccuracies and consequently to replacement of the clamping bolts. Likewise, no contamination and chips can get through, which ensures low-wear operation and reduces maintenance expenses.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

The Bumotec s1000 C horizontal transfer machine was designed to manufacture prismatic parts from round or profiled bar stock. Small and complex components can be efficiently machined in medium to large batch sizes. The machine is configured with seven 4axis machining stations, each equipped with 4 machining spindles (2 horizontal and 2 vertical). The eight stations comprise a 4axis cut off station with a single spindle. An optional ninth station allows the component to be reclamped to allow the sixth side of the component to be machined with an additional 3axis, 3 or 4 spindle machining unit. The machine is equipped with an automatic bar feed and quick change tool clamping system for optimum production rates. Features 9 machining stations Up to 36 tools integrated into the machine

Request for a quote

GSW SCHWABE AG

Germany

Paper Unwinder with a mechanical drag brake and conical clamping system, available in different sizes and versions for all types of coil reels and for all material widths Paper Recoiler, for all types of coil reels and for all material widths, with air motor or with electromotor

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quoteResults for

Quick clamping systems - Import exportNumber of results

9 ProductsCountries

Company type