- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- punching tools

Results for

Punching tools - Import export

BORNEMANN GMBH

Germany

The tool top (stamp) has an internal form, whose bottom part (matrix) has the corresponding opening (see image). These punch units are used in the areas of sheet shaping. Contact I have read and agree to the privacy policy. *Pflichtfelder

Request for a quote

KW HYDRAULIK GMBH

Germany

Battery Driven Hole Puncher 18 Volt Electric Driven Hole Puncher 230 Volt Hydraulic Hole Puncher Single Acting Hydraulic Hole Puncher Double Acting Selection Carts Brochure Punching Tools

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

Our specialty is “punching”. We have many years of experience in this area. We also solve your problems with our own tool and system construction.

Request for a quote

PRESSTA EISELE GMBH

Germany

Punch tools to work aluminium profiles Customized Production Single or Chain tools Holes, notches, bending Tool size up to 1.200 mm Power up to 800 KN

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

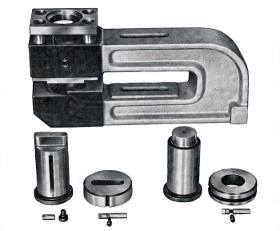

Punching units Punching unit with exchangeable cutting elements for sheets and profiles up to a material thickness of 25.0 mm and a hole diameter of 150.0 mm JOKA punching units consist of a special cast stand that accepts the punch and die and ensures the exact axis alignment between the cutting elements (punch and die). In addition, there is a stripping system in the upper part of the tool stand, as the material wipes off automatically after punching. The scraper contains two or more disc spring packages that guarantee perfect scraping even in the border areas. A fixed connection between the tool and the upper part of the press is therefore not required. To determine the exact position, each tool has a positioning pin (two for shaped holes) on the underside, which is precisely aligned with the cutting elements (center of the hole). The above picture shows a complete punching unit without cutting elements and one cutting set (punch and die) each for round hole or shaped hole.

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

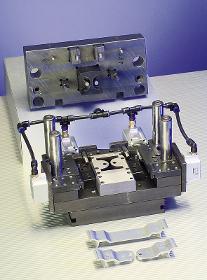

For the automation of your production, we develop and build semi or fully automatic hydraulic punching systems, tailored to your special wishes and needs.

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

For punching problems that cannot be solved with punching units in series and special designs, we manufacture tools and devices for every purpose.

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

Press-independent tools, for individual use or integrated in systems.

Request for a quote

PRESSTA EISELE GMBH

Germany

Base with hardened guides Hydraulic device; Motor 4,0 kW, 400 V, 50 Hz Operation panel to switch on/off single or multy head mode Foot pedal controlled C-formed stand, working range – ram to back wall 120 mm Daylight 280 mm, quick tool change Distance punch head to punch head min. 245 mm Punching power 60 / 120 kN, stroke 50 mm – stroke adjustable optionally Carriage with linear guides for manual adjustment in X-direction, with pneumatic clamps and positioning scale

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydraulic operated Foot valve operated Max. power at 260 bar = 400 KN Stroke = max. 80mm adjustable via limiter switch 20 Double strokes / min. Max. daylight = 300 mm Working range: ram to back wall = 200 mm Table dimension: 600 x 400 mm Quick change tool system

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydraulic operated Foot valve operated Max. power at 200 bar = 160 KN Stroke = max. 80 mm adjustable via limiter switch 14 Double strokes / min. Max. daylight = 250 mm Working range: ram to back wall = 130 mm Working range with turn table: ram to back wall = 90 mm Table dimension: 280 x 200 mm

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydropneumatic intensifier Foot valve operated Max. power at 10 bar = 90 KN Stroke = 40 mm 25 Double strokes / min. Max. daylight = 250 mm Working range: ram to back wall = 130 mm Working range with turn table: ram to back wall = 90 mm Working height 950 mm

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydropneumatic intensifier Foot valve operated Max. power at 10 bar = 50 KN Stroke = 37 mm Max. daylight = 200 mm Working range: ram to back wall = 110 mm Swiveling table to use tools to manufacture holes for sash bars

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KW HYDRAULIK GMBH

Germany

Punching Tools for Sheat Metall

Request for a quote

KW HYDRAULIK GMBH

Germany

Punching Tools for Bus Bars and Flat Material

Request for a quote

KW HYDRAULIK GMBH

Germany

Bus Bar Working Stations for Bus Bars and Flat Material Punching Tools for Bus Bars and Flat Material Cutting Tools for Bus Bars and Flat Material Bending Tools for Bus Bars and Flat Material Brochure Tools for Control and Switchgear Cabinets Tools for Laminated and Flexible Bars and Earthground Sheet Metall Hole Puncher DIN Mounting Rail Cutting Devices Wiring Duct Cutting Tool Punching Tools for Sheat Metall

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Processing of sealing foil on a roll, which is cut and sealed with a punching tool to fit the blister format. The additional fitting of an online printer is possible.

Request for a quote

PRESSTA EISELE GMBH

Germany

0 – 300 mm adjustable pneumatic material feed and digital display Vertical hydraulic punching unit to the right of the saw blade Power 200 KN Punching tools according to profile shape Aluminium profile – finished Cut to length Vertical punching Up to 8 profiles in one operation cycle Cycle time from 13 s / 1,63 s each piece Layout of punching tools for multiple profiles Quick change punching tools according to the profile shape Pneumatic material feed 8 profiles at once Special shaped quick change support Clamps according to profile shape – changeable Hydraulic punching unit Power 200 KN, stroke 20 mm Cycle spray mist device for each die and for the saw blade

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Run-in lubrication in combination with oil or grease lubrication Dry lubrication at sliding pairs, in particular under heavy loads and low sliding speeds, at oscillating movements or intermittent operation Dry lubrication at high operating temperatures (up to 450°C), shorter sliding paths and low speeds Dry lubrication in dusty environment, to avoid adhesions Coating of punching tools Advantages and benefits Highly effective due to good adhesion to prepared substrates Allows a low coefficient of sliding friction also under heavy loading Increased wear protection Radiation and vacuum-resistant Shortens and improves run-in conditions of friction bearings, toothings and other sliding pairs

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Run-in lubrication in combination with oil or grease lubrication Dry lubrication at sliding pairs, in particular under heavy loads and low sliding speeds, at oscillating movements or intermittent operation Dry lubrication at high operating temperatures (up to 450°C), shorter sliding paths and low speeds Dry lubrication in dusty environment, to avoid adhesions Coating of punching tools Advantages and benefits Highly effective due to good adhesion to prepared substrates Allows a low coefficient of sliding friction also under heavy loading Increased wear protection Radiation and vacuum-resistant Shortens and improves run-in conditions of friction bearings, toothings and other sliding pairs Also available as spray version OKS 511

Request for a quote

SPIROL

Germany

Since the development of coil springs in turret tooling, engineers have been challenged to increase the productivity of turret presses even further. In a traditional press, the option of material type and material thickness is limited by the coil springs inability to produce a high force in a short linear distance. When this performance is necessary, coil springs will have a negative effect on the quality of the formed product and efficiency of the manufacturing process. SPIROL® Disc Springs are the solution to form thick materials, large extrusions, and more complex designs. When stacked in series, they are capable of providing a greater, more consistent stripping force than coil springs and require less space. They have become an instrumental component in the advancement of turret punch press tooling. Visit www.SPIROL.com to learn more!

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling, sealing and capping machine for viscous products Capacity of the machine: 60 cycles/min. max. 3.600 jars/h Special features: Dosing pump with motorised Adjustment from 0 – 500 ml Heatable hopper with agitatork Output of the filled jars to the cooling tunnel and return to machine for sealing and capping Heatable filling nozzle with recovery system (drip-free) Foil lay-on station (from foil magazines or with punching tool) Sealing station (conduktive system or induction sealing) Capping station

Request for a quote

EFFBE GMBH

Germany

Our excellent reputation motivates us to tackle new challenges every day With the qualities EFFBE 295 and EFFBE Urelast®, EFFBE sets new standards in the service life and settling behavior of elastomer springs. Our elastomer springs stand for many years of permanently elastic and unbreakable use, for example in cutting and punching tools. Our customers around the world appreciate the quality of the EFFBE product ranges, which also offer a favorable price-performance ratio and high cost-effectiveness due to zero maintenance. Awareness of our excellent reputation motivates us to tackle new challenges every day. That's why our engineers and designers develop customized parts for you, if our standard ranges are unable to solve your problem. Elastomer compression springs are regulated by the standard DIN ISO 10069-1. Our qualities EFFBE 295 and EFFBE Urelast® meet this DIN standard and even surpass it in terms of service life and settling behavior.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FX-KT small trusses lift workpieces that cannot be picked up with a magnet in the center, such as rings, punching tools and flanges. Two FX magnets, adjustably mounted on a truss made of high-strength aluminum, provide a secure hold. With a few simple steps, the magnets can be removed from the truss and used individually.

Request for a quote

ZANDER GMBH

Germany

Three-dimensional shapes and tools implemented in steel and aluminum. Our services Moldmaking develops and manufactures tools for your products based on models, datasets and drawings. Manifold mandrels, tools for cooling water, fuel, heating and air hoses and other special applications Vulcanizing molds for air conditioning hoses with high accuracy in steel and aluminum Milling mandrels for hoses in stainless steel and aluminum Punching tools for elastomers Special production in steel, stainless steel and aluminum Turning - CNC machine CTX 420 with driven tools and Y-axis Milling - CNC machine DMU 80, five axes simultaneously

Request for a quoteResults for

Punching tools - Import exportNumber of results

51 ProductsCountries

Category

- Punching machine tools (12)

- Welding work - steels and metal (5)

- Metalworking - portable power tools (2)

- Silicones (2)

- Sheet metals - stamping (1)

- Anti-vibration supports (1)

- Custom packaging (1)

- Industrial cutting machine tools (1)

- Machine tools, cutting - parts and accessories (1)

- Magnets (1)

- Metalworking hand tools, non-power (1)

- Moulds and patterns (1)

- Portable power tools (1)

- Punching machines, plastic (1)

- Rolling mills - machinery and installations (1)

- Screw cutting - steels and metals (1)