- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- profile thickness measuring

Results for

Profile thickness measuring - Import export

MICRO-EPSILON

Germany

The profilometer thicknessCONTROL TCP8301.T-Offline is applied for sampling regarding the extrusion process of treads, side wall and inner liner material. The system offers measuring results in high precision and allows therefore an efficient production as well as a fully recorded quality control.

Request for a quote

MICRO-EPSILON

Germany

For the production of reeled resistors or sheet goods on roller head installations the thickness measurement is an essential factor for controlling and monitoring the production process. Applying systems of the RTP series, the profile thickness can be measured in various accuracy classes, thickness ranges and material widths.

Request for a quote

MICRO-EPSILON

Germany

For the production of reeled resistors or sheet goods in calenders the thickness measurement is a vital factor for controlling and monitoring the production process. By applying systems of the RTP series, the profile thickness can be measured in various accuracy classes, thickness ranges and material widths.

Request for a quote

MICRO-EPSILON

Germany

thicknessGAUGE C.LP sensor systems use laser profile scanners for the thickness measurement. These scanners project a laser line onto the surface to be measured. The laser line compensates for strip tilting and enables profile averaging. The laser line measuring technique makes it possible to measure the thickness of structured materials such as embossed surfaces and perforated plates.

Request for a quote

MICRO-EPSILON

Germany

For the steel and aluminum industry, Micro-Epsilon offers innovative measuring and inspection systems for thickness, profile and surface measurements. Performance and quality, as well as reliability of products and services have made Micro-Epsilon one of the leading suppliers of inspection systems for optical thickness measurement used in the metals industry. Our non-contact thickness measuring systems are used wherever high-precision thickness monitoring is required for control and quality assurance. Both in hot rolling mills, in continuous casting plants and in cold rolling mills and service centers, the Micro-Epsilon measuring systems operate reliably and with maximum precision. Numerous, successful installations in 13 countries around the world in milling lines and processing lines speak for themselves.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

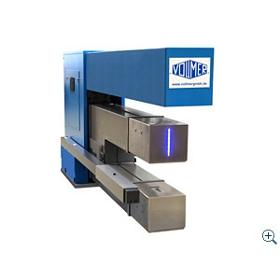

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The new standard for precision and speed With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of up to 80 kHz, they offer the precision and speed necessary for the control of the strip thickness. VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers. As with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible from 0.01 to 24 mm Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions for thicknesses from 0.01 to 24 mm. Precise even on wavy strip With a measuring precision of down to one micrometre per millimetre of strip thickness, they meet the demands of modern rolling mills. Contact gauges adapt to the strip passage and follow any waviness of the material.

Request for a quoteResults for

Profile thickness measuring - Import exportNumber of results

8 ProductsCountries

Company type