- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- products for plants

Results for

Products for plants - Import export

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

We manufacture gears, gear rings and toothed shafts for various applications in industry with a focus on mechanical engineering and heavy machinery. Our customers come from a wide range of industries: railway, wind power, marine, industrial gearboxes, oil and gas extraction, crane construction or construction machinery as well as special machines. We also supply the retrofit industry and manufacture the parts in small series or individual production. Depending on the dimension a quality of 4 can often be achieved. We examine the possibilities without obligation and without charge. Our customers include renowned and well-known companies. References to your industry on request. We manufacture according to customer drawings and have our own hardening plant. This saves time and costs during production. Cooperation exists for gas nitration and single-tooth induction hardening with experts in their field. ZWP supports you in the modernization of plants and machines (Retrofit).

Request for a quote

BORSIG GMBH

Germany

BORSIG offers comprehensive services for the power engineering, chemical and petrochemical industries as well as oil, gas and water supply. From our facilities Berlin, Gladbeck and Hamburg our exellently networked global team of engineers and technicians provide you with competent, fast and reliable support. We have decades of experience in planning, performing and implementing all kinds of assembly, manufacturing and service tasks. We rectify malfunctions and procure any required spare parts. We support you in the planning, delivery and installation of new components in your systems, modification, inspection and maintenance of existing components provided by us or third parties, and we also offer troubleshooting within the framework of a 24-hour standby service. Our services comprise: - Pressure vessels: Field service and repairs - Engineering - Boiler service - Piping - Workshop facilities for new production and overhaul of vessels

Request for a quote

VEHGRO B.V

Germany

"History and Origin of Quinoa Quinoa (Chenopodium quinoa) is native to South America and has been grown as the main food crop since 6000 years ago. Quinoa was already used by the Incas as a field product. The plant is able to grow under cold, nutrient-poor and dry conditions. The growth period is about 5-6 months. Through crossbreeding, quinoa varieties have been created which can grow in European and North American conditions. In the first half of April the quinoa is sown in Europe and the harvest takes place from mid-September. Production Process Quinoa Flakes After harvest, the quinoa is first cleaned. Then the quinoa is washed to remove the saponin. Then it is dried and the best pieces will be selected by hand. These pieces are soaked to flatten the quinoa. After drying, the quinoa is sieved and then processed into quinoa flakes. Healthy properties Quinoa Flakes <Quinoa flakes are rich in vitamins B2, E, iron, copper and magnesium. Quino…"

Request for a quote

TEMCA GMBH & CO. KG

Germany

Soft, voluminous and robust Airlaid-quality (100 % cellulose), highly absorptive and abrasionproof. High absorption rate, while soft and handy. The lightly embossed surface facilitates a very good cleaning efficiency. High wet strength due to a solid fibre texture. Material remains soft. Bio-degradable. Suitable for direct food contact (ISEGA-certificate). Main Fields of Application: For fast absorption of liquids and multi-purpose cleaning and wiping. In hospitals and nursing homes. In industry and production plants, in workshops, in food industry.

Request for a quote

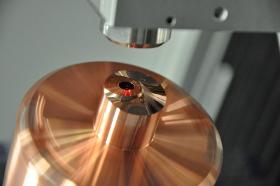

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Special purpose machines are our specialty. We are able to adapt our standard machines to your needs within a short time or to develop and build completely new machines for your application. Our extensive know-how allows us to accompany you from process development through the design and detailed construction of a suitable machine to measurement, commissioning and the start of production in your plant. In addition, even maintenance or product adjustments if necessary.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIMO GROUP GMBH

Germany

Flexible and individual solutions FRIMO offers many different solutions in terms of combining tool carriers, mix and metering units, and the peripheral equipment necessary to complete production plants. Individual and turnkey production solutions are therefore highly available.

Request for a quote

PERO AG

Germany

By documenting the required technical cleanliness and the processes of your chosen method, you obtain an unrivalled level of process safety at an early stage. You know that you will achieve the necessary technical cleanliness long before you integrate the cleaning unit into your production plant.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

The reliable generation, transmission and distribution of power can only be ensured with flawless technology in power plants – regardless of whether the focus is on crude oil, coal, natural gas, water or renewable energies. In order to meet the considerable predicted power consumption requirements worldwide, we are ready to provide assistance, with our products and our many years of experience in all of the stated applications with our two, three and four-spindle screw pumps, as a reliable partner. However, our pumps are not just found in power engineering plants such as power plants. When it comes to power transmission, our two and three-spindle ranges have been used successfully for many decades.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Combining plant eciency and reduced environmental impact Energy systems from Büttner provide stable process heat for your wood based panel production Process

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Hot gases are required for dierent industrial processes – particularly when it is necessary to heat drying systems directly. Büttner's line burners have been designed for robust and ecient use in the production of hot gases and are fuelled with natural gas. Gas line burners have been tried and tested in the wood processing, cement, mill-construction and many other industries across the world. Büttner's line gas burners are extremely robust, safe and maintenance-friendly Key features: Performance range from 0.8 MW to 48 MW Service-friendly modular design The burner ramps may be equipped with several gas-control sub-trains that may be individually deac Very low pressure losses across the burner (approximately 2 mbar) result in energy savings of more th

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The combination burner system BCB from Büttner functions as a ue gas generator for diverse industrial processes. Multi-fuel burners are commonly used to heat drum dryers or ash tube dryers.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Thermal oil systems are used in countless production processes: the process heat conveyed by using thermal oil is needed in a number of industries. Büttner's triedand-tested thermal oil heaters are heated with ue gas and are designed as single-pass Systems.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

For the construction of its steam generators, Büttner uses the experience in steam boiler construction established at the end of the 19th century and combines this with modern technology, guaranteeing safe and protable facility operations Key features: Indirect steam generation with thermal oil Direct steam generation with ue gas from biomass combustion Debrators or reners, wax smelters, sifters and heating for buildings are just some of the applications for steam generators. Design, construction, assembly and inspection of steam generators in compliance with EN, ASME or GOST norms

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Industrial Grate-ring systems are used very often in processes involving energy generation with solid fuels. Büttner's grate-ring energy systems are individually customized to the operator's needs and are exible when it comes to the fuel needed – whether it be waste wood, bark, or chips. Key features: fuels with a moisture content level between 20 - 150% based on bd combustion of waste wood (A1 - A3), wooden board wastes (MDF, PB and OSB), bark, wood chips, co air-cooled step grate sized from 12 to 90 m² ring capacity from 10 - 100 MW automatic de-ashing system graduated air-inlets low emissions

Request for a quote

SYGASTEC GMBH

Germany

for more Information pleasee see our web page https://www.sygastec-gmbh.com/cms.html

Request for a quoteResults for

Products for plants - Import exportNumber of results

16 ProductsCountries

Company type