- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production runs

Results for

Production runs - Import export

QUELLTECH GMBH

Germany

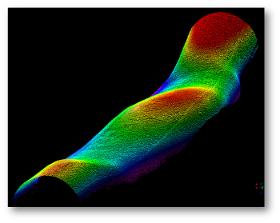

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote

IGUS® GMBH

Germany

DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv DryLin® N - Technical data DryLin® linear guide systems in the cleanroom DryLin® N - Applications DryLin® N - Design rules System selection & service life calculation NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. DryLin® N - Low profile linear guide system NK-02-17 DryLin® N - Low profile linear guide system NK-22-17-40 drylin® N - Low profile linear guide system NK-22-17-30 NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor DryLin® N low profile guide systems offer you low profiles in various widths. Like in all drylin® products, the carriage runs without lubrication in anodized aluminum profiles. The material used and the unique design make DryLin® N a cost-efficient and flexible guide system. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Rail made of anodized aluminum 2 Gliding elements made of iglidur® J or J200 3 Carriage made of chromated zinc or plastic 4 Carriage with threaded hole or through hole Advantages: Small installation height between 6 and 12 mm Lightweight Numerous carriage options – also with pretension Maintenance-free, self lubricating Corrossion-resistant Low wear with low coefficient of friction Rails in silver or black anodized When not to use ? When precision below 50 μ is required In high loads over 50 kg drylin® T drylin® R drylin® W When high resistance to chemicals is required drylin® W drylin® R DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv Standard, preload and floating bearing NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. 1. NW-01-27 standard 01 with through hole g 2. NW-02-27 standard 02 with threaded hole 3. Preload with through-hole or threaded hole 4. uinjection-molded with through-hole or threaded hole 5. NW-21-27-60P Vollkunststoffschlitten mit Durchgangsbohrung 6. NW-22-27-60P solid polymer carriage with through hole 7. NW-11-27-80 double carriage with through hole NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 1. Standard 02 with threaded hole 2. Injection-molded with threaded hole 3. Standard 01 with through hole NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P 1. Standard 02 with mounting nuts 2. Injection-molded with mounting nuts NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor

Request for a quote

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

Using thermoforming as an alternative to metal, foam or injection moulding often makes economical sense, especially where mid-size production runs or complex components are involved.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Compressed air blade To monitor the progress of certain processes, there is no alternative but to take frequent samples at the machine itself. This is normally possible only while the product is either moving slowly or stopped, and often results in complicated work-arounds to enable continual production (continuously running winders, etc.). The Samplecut FSC is the solution to the problem. The tried and tested sample cutter Samplecut FSC takes samples from fast running product.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Keeps web safely on track Drifting of the product web lateral to the running direction of product is unavoidable in some stages of textile finishing. The Ceremat system brings the product back on the right path. Applicationspecific variants are available.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Infrared pyrometer The Thermosense HP270 is used for non-contacting temperature measurement in driers and stenters and records the temperature of running product webs. The sensor is temperature-resistant up to 270 °C. It can therefore be mounted inside driers.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Reflexion of infrared light Automatic width measurement on a running product web. IR LEDs used in reflective mode continuously and precisely determine the product width. The sensor module only needs to be attached on one side of the product. The compact design allows it to be installed even in the tightest mounting spaces. Retrofitting is possible virtually anywhere.

Request for a quote

SPIROL

Germany

The SPIROL Model PH Heat Insert Driver provides an accurate and consistent method to simultaneously install multiple Threaded Inserts or Compression Limiters at multiple elevations. Simultaneous installation dramatically increases productivity and simplifies the number of manufacturing steps to complete an assembly. Additionally, the platen head and fixture can be easily changed to accommodate quick change-over to different assemblies associated with new production runs. This machine can be used to install 12 Inserts into 1 assembly, or a fewer number of Inserts into a larger number of assemblies – as long as the total combination does not exceed 12 Inserts.

Request for a quote

ROCHOLL GMBH

Germany

We love a challenge so we are more than happy to take on special designs. We translate your specifications into top-quality products. In order to meet the most stringent requirements, we rely on our comprehensive machine park and on the production facilities run by highly specialized partner companies. These machines have been designed to manufacture both individual items and batches without any problems. Would you like to have more detailed information on our special designs? Why not contact us directly? We will be happy to assist you. Milling of profiles Special concrete designs Rings for placing Shore test specimens Milling of dumbbell test specimens for tensile tests Multiple test specimens according to DIN 53281ff Stainless steel rings for tests according to EN ISO 10563 Spacers for standard joints according to ISO 11600 Spacers for elongation test according to ISO 11600, made of aluminum or PMMA in various % values Feed mechanisms

Request for a quote

CRB ANALYSE SERVICE GMBH

Germany

We offer you all common analytical techniques for quantitative and semi-quantitative XRF, X-ray fluorescence analysis of various materials on up to 71 elements of solids. Fast and reliable analyses with high precision and accuracy down to the trace element range, on request as an immediate service – accredited test procedures – Wide element range up to 71 elements from fluorine to uranium in one measurement run, suitable for product and raw material monitoring or analysis of unknown materials –Various preparation techniques such as melt fusion, powder compaction, non-destructive measurements

Request for a quote

LUTZ PUMPEN GMBH

Germany

Eccentric screw pump tube B70V-D Industryfor three-phase motors For pumping highly flammable liquids and for use in "Zone 0", use Pump tubes with Mechanical seal (GLRD), cardan shaft (GW) and PTFE stator. The B70V-D 12.1 Eccentric screw pump in the industrial version is a powerful positive displacement pump for medium, highly viscous and viscous media up to the limits of flowability. Depending on the application, various three-phase and air motors are available, which you can combine with the Pump tube at any time. * PTO shaft versions also available in special immersion depths of 500 - 2000 mm * Media examples: viscous mineral oils, resins, emulsions, paints and many other thick materials. * Uniform volume flow * Gentle, low-pulsation product conveying * Smooth running and low wear * Large selection of robust and powerful drive motors * Approved according to ATEX Directive 2014/34/EU, Category 1/2

Request for a quote

LUTZ PUMPEN GMBH

Germany

Eccentric screw pump tube B70V-D Industryfor three-phase motors The B70V-D 120.1 Eccentric screw pump in the industrial version is a powerful positive displacement pump for highly viscous, pasty and viscous media up to the limits of flowability. Depending on the application, various three-phase and air motors are available, which you can combine with the Pump tube at any time. This means you are flexible at all times and thus conserve important resources. * available in special immersion depths of 500 - 2500 mm on request * Connection to the discharge nozzle of the pumping station is made with a Tri-Clamp * Media examples: highly viscous mineral oils, resins, emulsions, paints and many other thick materials. Features & Advantages * Uniform volume flow * Easy and fast cleaning * Gentle, low-pulsation product conveying * Smooth running and low wear * Large selection of robust and powerful drive motors

Request for a quote

LUTZ PUMPEN GMBH

Germany

The Eccentric screw pump B70V-D in PURE design is a powerful positive displacement pump for medium, high viscosity and viscous media up to the limits of flowability. Depending on the application, you can choose from a range of different rotary current motors, which can be combined with the Pump tube at any time. This gives you flexibility at all times and saves important resources. * also available in special immersion depths * Media examples: viscous cosmetic products, food and etc. Features & Advantages * Uniform volume flow * Easy and fast cleaning * Gentle, low-pulsation product conveying * Smooth running and low wear * Large selection of robust and powerful drive motors * Approved according to ATEX Directive 2014/34/EU, Category 1/2 * The maximum flow rate is a value determined by means of a test bench and measured with water at a liquid temperature of approx. 20 °C .

Request for a quote

SPANSET SECUTEX GMBH

Germany

“Heat”resistant buffer pad For hot processing. Nonferrous metals, such as gold, copper or brass, get hot during processing and have a sensitive surface. Rollers and cylinders coated with secutex Heat protect bar stock during production; abrasion and run marks are reliably avoided. Operating temperature up to 140°C Apart from the positive mechanical and chemical properties, secutex Heat is an elastomer material for operating temperatures up to a maximum of 140°C. Operating temperature up to 180°C As an option, „Heat“ can be finished with an aramide fibre surface. The operating temperature thereby even increases to a maximum of 180°C.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

The FireBird® Pro S Gold Edition with mechanical setting stroke adjustment. When setting a blind rivet nut size of the same length in consistent material thicknesses constant setting stroke should be used. The setting stroke corresponds to the distance the mandrel is drawn into the nose piece during the setting process and thus how far the blind rivet nut is upset. With the setting stroke adjustment this path can be set mechanically on the setting tool. Customer benefits of setting stroke adjustment: • Device control via setting stroke adjustment guarantees a constant height of the blind rivet nut after setting • Stepless setting of the setting stroke • Setting stroke adjustment is preferred above all by experienced users and for large production runs Technical data, working range and advantages are analogous to FireBird® Pro Gold Edition More details on delivery limits will be answered in a specific enquiry (details are only exemplary)!

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Semi-automatic machines for single cuts and small seriesWith automatic saw feed and quick-clamping device for the material, the semi-automatic models offer higher cutting output levels and more operating convenience than the manual saw variants. By ensuring fatigue-free working for the operator, they are also suitable for sawing small production runs: Quick-acting pneumatic / hydraulic clamping device Clamping pressure reduction available as option Variable hydro-pneumatically / hydraulically controlled setting of the saw blade feed Easy miter cutting positioning with fixed stop Easy stroke adjustment of the saw unit via 2 clamping levers Well dimensioned worm gear unit with EISELE shock-absorbing feature Quick and easy blade change

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Planetary cutting machine for corrugated metal and PTFE hoses. Cutting results that often eliminate an additional step. This completely unique planetary cutting machine delivers almost scrap-free production and high efficiency. With a completely variable centering clamp system, all hose OD to the maximum rating for the machine can be cut. Approximate cutting time is 25 seconds for 1 ¼“ (ø DN 32). Productive and ergonomic •No dramatic flaring of the stainless steel braid •Reduces or eliminates time-consuming manual preparatory work thereby increasing productivity and lowering costs •Centering hose clamp system •Shortest cut possible from 10 cm •Minimizes personnel costs and preparatory work •No wrapping/unwrapping with adhesive tape required •Clearly laid-out user friendly software on a panel with a 6“ color display screen •Large article memory promotes productivity •Reference run for optimal positioning of the cutting blade for cutting all hose diameters CE compliant

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BAGOBAG GMBH

Germany

Nylon & Polyester Bags bagobag, the bag manufacturer for Your contract: You and Us. How can We work together? Together with our manufacturers in the bagobag team, you develop the carrying bag you need and imagine step by step, using your initial data and the bag's purpose, which you define in the development stage. Incredibly, these types of custom series are no longer unaffordable today. They're our everyday business. Everyone can produce and design a custom bag with us, and print it in small or large orders.The planning and modeling for a carrying bag production run occurs step by step: A Rough Sketch of the Bag's Ideal Characteristics A rough idea of the characteristics of the bag needs to include all available details. You can know only a few of these characteristics and leave some parameters up to us. These few details can be based on the eventual intended use of the bag or the type of bag you need: sports bag, sample carrying bag, team bag, cosmetic case, pillow packaging..

Request for a quote

HUBTEX MASCHINENBAU GMBH & CO. KG

Germany

Safe and as fast as possible – those are the crucial prerequisites that modern tool changers need to satisfy. HUBTEX tool changers with load capacities of up to 65 tonnes help to reduce the changing times for pressing and stamping tools and so improve production efficiency. The compact running gear also allows for extremely low entrance heights underneath machinery. Load capacities up to 65,0 t Tool platform with lift hights up to 3000 mm

Request for a quote

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser produces highly precise presses for the metal forming industry, thus increasing productivity, quality, and lifetime and decreasing overall operating costs. ANDRITZ Kaiser has delivered more than 8,000 presses for numerous customers world wide, each different in its application. A large number of factors have to be taken into account when deciding on the right press: technical requirements from the product, expected productivity, technical requirements on the press line, integration into the existing production lines, fixed and running costs, process control, fast availability of maintenance/service, availability of spare parts – all these considerations influence mainly the total cost of ownership. Our press solutions are: Conventional high speed presses from 630 kN up to 4,000 kN Conventional stamping and deep drawing presses from 1,000 kN up to 8,000 kN Cutting presses from 1,600 kN up to 6,300 kN Heavy presses from 10,000 kN up to 25,000 kN Servo presses from...

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Separation of paint powder from powder coating booths. Options: Rippert powder filter This type of filter is particularly suitable for the separation of paint powder from powder coating booths and is also often used together with an upstream Rippert cyclone for powder recovery. Separation chamber with dust collecting container, filter cartridges, compressed air cleaning and sound-insulated fan are housed in a compact design. The filter cartridges are arranged vertically in order to ensure optimum cleaning behaviour and energy-efficient operation. The fan, which also comes from our own production, is characterised by smooth running and high efficiency. Standard advantages:

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

PTFE fiber packing with mechanical reinforcement, PTFE Impregnation, Run-In Lubricant and elastic EPR Tube Core Practical useful application data: due to Elastomeric core max. temperature: +150 °C Characteristics High cross section density and structural stability, yet elastic and adaptive for bigger radial shaft run out Suitable for vacuum Mechanical stability for products with abrasive content Improved recovery Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Temperature: t = -50… +280 °C pH: 1 - 13 Density: 1.45 g/cm³ Practical useful application data: due to Elastomeric core max. temperature: +150 °C Main application Mixer Agitators Autoclave Kneader Paddle dryer Suitable for Equipment with radial run out and products with abrasive content Form of delivery This packing can be manufactured from 14 to 40 mm square as well as in intermediate, inch sizes and special measurements. 14 mm and above on 5 kg spool Special length, pre-cut or die formed rings on...

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer head space moistener permits moisting of the cap with the fluid in the container. Machine dimensions depend on the conveyor performance and the desired moisting time. Moisting occurs during continuous material flow. The machine is a space-saving solution due to the vertical moisting track. The design permits products to run through the machine without turning process, if necessary. Technical data: —Conveying performance: up to 60,000 units/h —Moisting path: up to 10 m —Product weight: up to 40 kg —Product width: 20 - 450 mm —Solid steel construction in painted or stainless-steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain optional equipment: —deflecting pulleys —motorized width adjustment —machine cover made of Makrolon or steel grid with maintenance doors —electrical control system —loading and unloading belts

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

O-ring applicator LA-CE for around the corner application (for ALX 92x): • Easy solution for labeling adjacent two sides of a product with a single label • Suitable for integration in box closing systems • Product runs into applicator which applies a label around the corner on the moving product

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The large storage tank facility provides the opportunity to stock sucient quantities of glue, emulsion, liquid hardener, release agents, etc. This ensures that production runs smoothly Features, function Both the tank volume and the tank design are variable, which means that they may be perfectly adapted to the available space of the site. with devices to prevent overlling. Levels are monitored by pressure or radar sensors visualisation. This enables operators to respond to low quantities in time. between tanks allow maintenance to be carried out on individual components without it being necessory to stop production The downstream transfer systems, which include pumps, lters, sensors and fittings have been adaptod to the medium and are always completely pre assembled

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

In our product area you will discover Eltex charging systems for many industrial sectors. Do you have special requirements, such as small production quantities or little space? Are you interested in solutions for electrostatic charging? Simply contact our consultants – and find the right charging system and solution to optimize your processes with electrostatic charging. A universal bar with minimal dimensions for supply voltages up to 60 kV. It is used to charge surfaces for blocking and tacking purposes. The charging bar is mainly used where production processes and cycles run faster and with less interference if the materials used (such as films, foils, papers, etc.) adhere to each other. The parallel configuration of two or more bars allows surface-covering charging or operating the unit at high web speeds.

Request for a quote

TAMPOPRINT GMBH

Germany

There was a need for coming up with a new pad printing machine, the basis of which opens up new target markets for us both technologically and in terms of applications. The result: the development of the SPEED 40-2 pad printing machine. Its output: as many as 9,000 cycles/h in continuous run. The production quantity is max. 18,000/h printed parts (single color with a printed image size of Ø 37 mm). Very high true-to-register printing, precision contours and photo and line images. The SPEED is a built-in execution, suitable for any kind of clocked, linear or rotary transfer systems. Thanks to its integrable misprint device there is no stopping of the machine in the absence of a workpiece. The power costs are low in comparison to the cycle number (part output). The SPEED 40-2 is a fast shortstroke machine of a new series of pad printing machines.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Frequently, a production run starts or ends with the automatic feeding or removal of workpieces. Our feeders and stackers are produced in various capacity levels, with vacuum suction traverses, with or without pit. The VEN BRUSH system equipment Solutions possible with the VEN MOVE series cover several functions such as rotating, turning, transferring, stacking, feeding, accumulation, separation or allocation.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

b.dry chains are made from corrossion-free, maintenance-free CF stainless steel with an optimized articulated link that represents a masterpiece of high precision. The secret of the b.dry range is to consign the old notions of „steel on steel“ to the past! The fact that no lubricants are needed is thanks to our b.dry bushes, which are made from a special, high-performance polymer. The capabilities of this material are absolutely unparalleled. b.dry products run completely dry, but are still more resistant to wear and corrosion, stronger and have a longer service life than comparable chains.

Request for a quoteResults for

Production runs - Import exportNumber of results

35 ProductsCountries

Category

- Pumps (3)

- Textiles - Machines & Equipment (3)

- Milling - steels and metals (1)

- Electronic components (1)

- Automation - systems and equipment (1)

- Bags (1)

- Clothing accessories (1)

- Conveyor belts (1)

- Cutting - machine tools (1)

- Engineering - industrial contractors (1)

- Environmental monitoring laboratories (1)

- Import-export - mechanical engineering (1)

- Industrial maintenance (1)

- Labelling machines (1)

- Machine vision system (1)

- Mechanical transmission systems and components (1)

- Monitoring and control equipment (1)

- Packaging (1)

- Pad printing (1)

- Portable power tools (1)