- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure monitoring

Results for

Pressure monitoring - Import export

APT ANGEWANDTE PROZESSORTECHNIK GMBH

Germany

Overpressure and vacuum possible - Different pressure and flow ranges possible - Several measuring ranges possible in one device - Modern operation via 5" touch graphic colour display - Completely remote controllable, optionally via ProfiNet

Request for a quote

INFICON GMBH

Germany

The INFICON Pirani Gauge Display PGD400 in combination with the INFICON Pirani Standard Gauge PSG5xx provides a cost effective pressure monitoring solution. Although it is called Pirani Gauge Display the PGD400 also supports our PCG55x and MPG series vacuum gauges.

Request for a quote

BOURDON HAENNI GMBH

Germany

Bourdon takes mechanical pressure monitoring into the digital age This innovative device fits to any comprehensive platform for machine and process monitoring as well as the preventive maintenance of equipment which is supported by a LoRa wireless protocol. Key applications include pressure measurement and monitoring for oil refineries, petrochemical industry and biodiesel plants. More predestined applications are in waste and water treatment, power generation and transmission, general process industry, building services and civil engineering. The right choice when industry grade wireless pressure measurement and monitoring is required

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The preeflow® controllers simplify every dispensing process. They are perfectly matched for all dispensers within the eco-PEN, eco-DUO and eco-SPRAY series. The eco-CONTROL EC200 2.0 serves primarily to control and parameterize the preeflow® dispensers. In addition, pressure monitoring is carried out by the controller for a reliable process with precise dispensing results. The control unit can be easily integrated into fully automatic systems and meets all requirements of modern dispensing processes. The eco-CONTROL EC200 2.0 offers a compact solution with an integrated power supply unit. The control unit also offers options for pressure and temperature monitoring, 100 program memory locations and enables fast and clean storage of programs. The control unit can also be integrated with PLC systems.

Request for a quote

TFP TECHNOLOGY GMBH

Germany

We at TFP use our special wire and fiber laying technology to create sensors for large dimensions to measure pressure, humidity and monitor structural composite parts. Please contact us for further information.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoDuo-VM 2-component dispenser is a valveless dosing system for static mixing based on the proven progressive cavity technology and thanks to its purely volumetric precise dosing principle, is ideally suited for high-precision dosing tasks. Built according to modular structure, a configuration of the 2-component dosing systems as well as maintenance and part exchange at module level is possible. The material components are mixed downstream of the mixing head only in the mixing tube to prevent material hardening in the system components of the mixing head. Your advantages: - repeatable dosing volume even with viscosity and density fluctuations - Processing of low to high viscosity materials with low to very high filler content - Dispenser and mixing head segments can be combined in size due to modularity - standard equipment with dead space-free integrated dosing pressure sensors for online process monitoring - simple assembly/disassembly of the components

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Automated emptying system for containers up to approx. 30 liters ▪ Volumetric conveying progressive cavity pump based on the endless piston principle ▪ Pulsation-free and precise emptying and material supply to 1C and 2C dispensing systems ▪ In redundant dosing systems applicable ▪ For medium to high viscosity materials ▪ For structure sensitive, filled, abrasive materials ▪ Application for cylindrical or slightly conical metal and plastic containers ▪ Housing for machine safety and protection against dirt contamination ▪ Automatic retraction and venting the container as well as detection of media surface ▪ 4“-Touch panel with function keys for comfortable setting and parametrization of the system ▪ Externally controllable via Profinet interface ▪ Continuous determination of the position of the follower plate and level monitoring ▪ Adjustable pressure reduction for longer pauses

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Working range: Blind rivets up to Ø6.4 mm of all materials /except high strength blind rivets) and BULB-TITE® blind rivets up to Ø7.7 mm of all materials. (max. mandrel Ø 4.3 mm). Technical data: • Radio connection: WiFi 2.4/5.0 GHz and Bluetooth • setting force: 15.000 N • Weight: approx. 2.5 kg incl. battery (2.0 Ah) • Drive: Brushless motor (BLDC) • Device stroke: 25 mm Scope of delivery: • Mouthpieces: 17/32, 17/36, 17/40 and 17/45 Customer benefits: • Safe process due to setting process monitoring • Force/displacement diagram • Optionally up to 3 evaluation windows (WinTech) • Optional pressure monitoring possible • Complete documentation of the process (database) • Status and errors available in the network for maintenance purposes • Quality control takes place during production • Brushless motor, therefore extremely fast and almost wear-free • Flexible use

Request for a quote

SFS GROUP GERMANY GMBH

Germany

• Blind rivet sizes from 4.8 mm to 8.0 mm Ø all materials • Rivet body lengths up to 35 mm • Setting head diameter up to 19 mm • Mandrel up to 5.5 mm Ø • Traction power up to 20,000 N at 5 bar air pressure • Conveyor pot filling level display • Operating pressure: 5 bar • Vibration-dampened pressure intensifier attachment • Multiple monitoring of the blind rivet pistol by means of sensors • Industrial control with an 8“ colour display • Conveyor distances of up to 25m are possible when used in fully-automatic production systems • Maintenance display, simple fault diagnosis • Customer-specific software modification is possible • Ideal for applications that do not require any process monitoring • Rivet mandrels are disposed of via a vacuum system • Surface contact trigger optional available • Can be integrated into the system or operated independently • Interface for external memory-programmable control system (SPS) can be realised via the GESIPA®- Interface

Request for a quote

BDSENSORS GMBH

Germany

The compact low-cost digital pressure gauge DM 10 is battery-powered and has an adjustable housing; it is thus extremely suitable for mobile pressure monitoring. The 4.5-digit LC-display indicates the battery status, the mea-surement value as well as the unit, this enables a fast and precise reading. It is possible to switch between the most common units (bar, psi, Pa, MPa). Additional functions as auto-zero, min / max values and an automatic switching-off complete the DM 10 profile. Features: — nominal pressure: 0 ... 1.6 bar up to 0 ... 250 bar — accuracy: 0.5 % FSO BFSL (class 0.5) — ceramic diaphragm — adjustable housing — LC display, 4.5-digit 7-segment display — standard battery CR 2450 operating period > 1.800h Optional Features: — min / max function with reset function — auto-zero — setting the pressure unit — automatic switch-off cofiguration

Request for a quote

ORBITEC GMBH

Germany

The PPA 2500 purge pressure analyser is used for setting an monitoring the ID purge pressure. It replaces the analogue Magnahelic devices traditionally used for applying the ID pressure balancing technique used for producing high-quality “controlled profile” welds on small diameter applications. The connection with the Tigtronic Orbital 4, Tigtronic Compact and EVO controllers enables documentation. Package includes: — Purge Pressure Analyser — Sampling Hose — 6mm T-fitting — Calibration certificate — Plastic box

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Membrane and bladder accumulators are important components of modern hydraulic systems. Monitoring the nitrogen pressure level is becoming ever more important for ensuring correct operation. The STAUFF Accumulator Adaptor together with the PT-RF pressure sensors allow maintenance personal to quickly and easily check the accumulator pressure without pressure loss. Pressure values, serial numbers, date and time will automatically be stored in the memory of the reader and then easily and conveniently read out on the PC later on. For this, the Accumulator Adaptor is screwed onto the nitrogene connection of the accumulator and a PT-RF pressure sensor is attached at the side. ▪ max. Pressure: 400 bar / 5801 PSI ▪ Burst Pressure: 1600 bar / 23206 PSI ▪ Sealing Material: NBR (Buna-N®)

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

General Information The STAUFF SPG-DIGI digital pressure gauges are designed for digital measurement and display of pressure in hydraulic systems, especially for oils, lubricants and water. Current measured values as well as min and max values can be displayed with a precision of 0.5% of the full scale value. The SPG-DIGI is optionally available in the USB version, equipped with an internal data memory. A measurement started on the measuring device is automatically stored in the internal data memory in the universal .csv file format. The measurement data can then be transferred to the PC using the supplied mini USB cable. The device shows up on the PC as a USB data storage medium, so that no additional software is required for transferring the data. This allows easy export of the data, e.g. into Microsoft Excel®. The measurement data are stored in the internal memory with a resolution of up to 100 ms for short measurements and a pressure peak monitoring of 10 ms. Up to ten...

Request for a quote

DRIESEN + KERN GMBH

Germany

Pipe Network Monitoring The DK680 is a robust data logger for measuring pressure in gases or water, and optionally also for measuring temperature. When monitoring pressure in pipe networks the device can detect short-term fluctuations as well as long-term changes in pressure thanks to a sampling interval between 8 Hz and 24 hours. Applications · Pipe network analysis · Interference analysis in pipelines · Leakage Tests · Pipe nework monitoring · Monitoring in air pressure systems Features · Robust pressur data logger · 3x optional programmable input channels, e. g. for temperature, voltage/current, pulse · Direct measurements on LCD · Excellent measuring accurcy · Large memory capacity for up to 4 million readings · USB interface · Sampling interval programmable from 8 Hz tp 24 hrs · Battery life up to 8 years · "Stop-when-full" or "continuous" logging modes · LED indicators for alarm conditions

Request for a quote

FILLTECH GMBH

Germany

Filltech's most advanced pumping technology: High-end CO 2/N 2O pump designed for automatic redundancy and fail-over Highlights Intelligent interoperability with any Filltech filling station Optimized energy consumption Complete plug & Play system ready for instant connection Safe operation through intelligent monitoring: pressure, temperature, leakage Low noise emission Application ready: filling, dozing, transfer, supply Joint pumps for flow-rates up to 6 tons Remote operations: Monitoring, remote control, power control Technical Data Capacity: 400 - 1500 kg/h, 6-25 lpm, 1.7 -6.6 gpm Power supply: 3 x 400V / 50 Hz, opt 120 / 208V, opt. 277 / 480V/60Hz, 3-phase Power consumption: 1.5 to + 4 kW/h (dep. on pump size) Dimensions (LxWxH): 900 x 900 x 1670 mm / 35 x 35 x 66 in. Pump Triplex plunger pump NP 25/50 – 25/70 Motor: Belt drive Construction characteristics CO 2 supply: liquid from tank system Ring- or stub lines Automatic start cycle Pressure supply needed for valve: 8 b

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

PROCONTROL Precise metering and constant pressure of sealing water (p = 1 bar above media pressure) - environmental protection and cost reduction in fact of reduced seal water consumption Flow and pressure monitoring - protects the aggregate from failing (inductive alarm system) Stable and compact construction guarantees safety and simple handling Corrosion and temperature resistant Displays are easy to read and clean With an inductive switch (special component) alarm system can be used. Technical parameters Flow range 0.5 up to 1.5 ltr/min 0.5 up to 3.0 ltr/min 1.0 up to 8.0 ltr/min 2.0 up to 15.0 ltr/min Temperature: t = … +80 °C Pressure: p = 10 bar (Option 25) Main application Pumps with mechanical seals with flush port Stuffing box packings with lantern rings Suitable for All Industries Accessories and options Pressure valve for creating blocking pressure Pressure Gauge Stand Inductive switch Hoses, connecting...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Flow-Trigger™ is an industrial flow switch designed and calibrated to confirm minimum or maximum flow rate within a pipeline. The Flow-Trigger™ combines a fully calibrated flow orifice and an explosion proof differential pressure switch to reliably monitor gas flow within the most demanding hazardous industrial environments. The Flow-Trigger™ is designed to be suitable for use with most industrial gases including hydrocarbons and corrosives like ammonia. Every Flow-Trigger™ comes complete with an orifice calibration curve and is preset to trigger at the desired set point based on the provided inlet gas specifications. The switch is field adjustable (+/- 40% of initial flow set point) after installation so that it can be fine tuned to meet specific application requirements. The Flow-Trigger™ is designed to be easily installed directly into a gas pipeline and comes complete with the required inlet and outlet pipe to maintain calibration accuracy.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

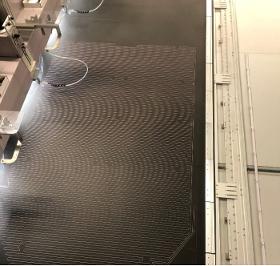

Scope of application: -Horizontal & vertical use - therefore suitable for vertical & horizontal CNC milling machines -Conventional clamping, grip clamping & low tension clapping possible -Titanium 2 K - ideal for use on 5-axis machining centers -Clamping of raw, thermal & saw cut parts by penetrating hardened and interchangeable grip elements into the work piece -The support jaws safely and cost effectively allow raw part, different types of materials & complex geometries to be handled Product features: -To monitor & optimize milling processes -Safety for people & machines -High flexibility - the modular clamping system combines almost all possibilities of our tried and tested models -Titanium 2 M - finely polished sides so that all sides can be used -Titanium 2 K & M can be vertically used -Force translated high-pressure spindle. -Increased power stroke for safe clamping of raw parts -Loss of 8 mm clamping edge in low tension, 3 mm with GRIPP

Request for a quote

HALSTRUP-WALCHER GMBH

Germany

The portable, battery-operated KAL 84 calibration system combines a pressure transmitter and pressure gauge. These can be used to test and calibrate pressure sensors and other pressure gauges for low pressures both quickly and easily. A high degree of accuracy and excellent reproducibility of results combined with a robust design give the system all the functionalities required for laboratory and service applications. Calibration in mmHg (optional) makes the system ideal for applications in accordance with the regulations for users of medical products, e.g. blood pressure monitors and infusion/suction pumps.

Request for a quote

HALSTRUP-WALCHER GMBH

Germany

The P 34 differential pressure transmitter is designed for pressure monitoring applications in cleanrooms, laboratories, pharmaceutical plants and operating theatres as well as for special uses in machine and plant construction. As well as measuring the differential pressure, the instrument also records positive and negative overpressures as well as flow rates or volumetric flows. The measuring range is scalable in the range from 10 .. 100 %. Two optional contact points allow the user to connect visual or audible alarms that are triggered any time values rise above or fall below specified limits. The transmitter can be configured easily via an USB interface (optional) with software. A selectable time constant allows the transmitter to be adjusted perfectly to the pressure conditions and thus ensures a stable output signal. The P 34 can be mounted on top-hat rails.

Request for a quote

HALSTRUP-WALCHER GMBH

Germany

This compact differential pressure transmitter is particularly suited to filter and pressure monitoring applications in the heating, air-conditioning and ventilation industries. An optional display allows measurement values to be read directly on-site in Pa or kPa. An optional time constant (up to 4s) allows the instrument to generate an attenuated output signal, even under fluctuating pressure conditions. To reduce wiring costs, the instrument is also available in a version with two-wire technology (optional). The PS 27 can be mounted either on a wall or on top-hat rails. The instrument is available with an ISO factory calibration or DAkkS calibration certificate (optional).

Request for a quote

HALSTRUP-WALCHER GMBH

Germany

The P 26 differential pressure transmitter is designed for pressure monitoring applications in cleanrooms, laboratories, pharmaceutical plants and operating theatres as well as for special uses in machine and plant construction. As well as measuring the differential pressure, the instrument also records positive and negative overpressures as well as flow rates or volumetric flows. The measuring range is scalable in the range from 10 .. 100 %. Two optional contact points allow the user to connect visual or audible alarms that are triggered any time values rise above or fall below specified limits. The transmitter can be configured easily via an USB interface (optional) with software. This can also be performed using a keyboard and display (optional). The measured values can be displayed in all standard units. A selectable time constant allows the transmitter to be adjusted perfectly to the pressure conditions and thus ensures a stable output signal.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The large storage tank facility provides the opportunity to stock sucient quantities of glue, emulsion, liquid hardener, release agents, etc. This ensures that production runs smoothly Features, function Both the tank volume and the tank design are variable, which means that they may be perfectly adapted to the available space of the site. with devices to prevent overlling. Levels are monitored by pressure or radar sensors visualisation. This enables operators to respond to low quantities in time. between tanks allow maintenance to be carried out on individual components without it being necessory to stop production The downstream transfer systems, which include pumps, lters, sensors and fittings have been adaptod to the medium and are always completely pre assembled

Request for a quote

HALSTRUP-WALCHER GMBH

Germany

This pressure transmitter is particularly well suited for monitoring filters and pressures in HVAC (heating, ventilation and air conditioning) applications. DIP switches allow users to configure the output signal and switchable measurement ranges (optional). Settings provide an option for conversion to a root-extracted output signal (displayed as a % of the maximum output value). An internal button is also available for performing a zero-point correction or fine-tuning the end value. An optional display allows users to read the measured value directly on site in Pa or kPa. With an optional time constant (up to 10s), the instrument can produce an attenuated output signal, even under unstable pressure conditions. An optional two-wire version of the device is also available for reducing wiring complexity. In addition to simple wall-mounting with just 2 screws, the PS 17 is also suitable for mounting on top-hat rails.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS high operating safety robust, compact design pressure resistant up to 350 bar easy maintenance flow direction selectable drag indicator as standard Dual scale bar / psi or mbar / kPa universally applicable selectable display indicating range OPTIONS helium application on demand plastic housing stainless steel housing static pressure max. 450 bar GENERAL The differential pressure gauge DP 900 serves to monitor the differential pressure of filter systems, measuring systems, valves, coolers, heat exchangers, in petrochemical, as well as in gas and air systems. Preferably, the DP 900 is applicable for air and gas technical systems. The gauge housing made from aluminum is designed compact and robust. It is pressure-resistant up to 350 bar. FUNCTION A determined path of a freely movable piston measures the differential pressure. The piston retains against a compression spring. The magnetic spool-measuring device unit is been installed to the main housing.

Request for a quote

GEORG SCHÜNEMANN GMBH

Germany

SAB‘s F450 Self-Cleaning Filter automatical-ly cleans all low viscosity fluids at high output flow rates. No matter if it is during filtration of aggressive fluids, desalination, industrial pro-cess or power station cooling, the F450 will meet the need. This system reliably protects heat exchangers and other downstream com-ponents from clogging and fouling. - Significantly longer service life because of Bernoulli-princip - Continuous filtration without process interruption - Time or pressure differential controlled cleaning process - DN32 up to DN600 - 5 m³/h up to 4400 m³/h - Individual construction with support to material, quantity and position of connections - Filtration degree from 150 µm upwards - pneumatic or electric drives - ATEX-approval - Implementation of control units into higher level control and monitoring systems - Low pressure drop - Operational from 0,7 bar upwards

Request for a quote

HYDROSTAR MESSTECHNIK GMBH

Germany

Our mechanical pressure switches are entirely “Made in Germany”. Hydrostar’s extensive and long product experience along with continuous improvements in hydraulic pressure measurements enables the production of high-quality, accurate and reliable mechanical pressure switches. These properties have proven themselves consistently worldwide. The core of the pressure switch line is the special extreme long-lasting sealing combined with the piston-springprinciple and its exceptionally accurate and reliable change-over switch. The minimum switching path with an additional throttle bore allows for a lengthy and durable life cycle. Another special feature is the potential adjustability of the pressure switch on client-side, even after the installation. Mechanical piston pressure switch for pressure monitoring Pressure range 5 to 350 bar Special Features Precise and Reliable Compact Design Change-over switch High overpressure security

Request for a quote

HYDROSTAR MESSTECHNIK GMBH

Germany

Our mechanical pressure switches are entirely “Made in Germany”. Hydrostar’s extensive and long product experience along with continuous improvements in hydraulic pressure measurements enables the production of high-quality, accurate and reliable mechanical pressure switches. These properties have proven themselves consistently worldwide. The core of the pressure switch line is the special extreme long-lasting sealing combined with the piston-springprinciple and its exceptionally accurate and reliable change-over switch. The minimum switching path with an additional throttle bore allows for a lengthy and durable life cycle. Another special feature is the potential adjustability of the pressure switch on client-side, even after the installation. Mechanical piston pressure switch for pressure monitoring Pressure range 5 to 600 bar Special Features Precise and Reliable For hard conditions Change-over switch High overpressure security

Request for a quote

FLOW EUROPE GMBH

Germany

The Mach 3 series offers you the world’s most reliable ultrahigh-pressure pump, intelligent process monitoring, and an array of unparalleled options all integrated into the most powerful waterjet control available. This system configuration incorporates a design that combines the motion control, pump and high-pressure components into one compact machine. It consumes minimal floor space, provides excellent operator access, and is configured for easy material loading and unloading.

Request for a quoteResults for

Pressure monitoring - Import exportNumber of results

30 ProductsCountries

Category

- Precision measuring instruments (4)

- Pressure regulators (2)

- Pressure switches (2)

- Automation - systems and equipment (1)

- Flowmeters (1)

- Applicators for adhesives and glues (1)

- Calibration equipment (1)

- Dosing - machines and equipment (1)

- Dosing pumps (1)

- Fastening devices (1)

- Machine tools - metal machining (1)

- Manometers (1)

- Measurement and control instruments (1)

- Measurement and regulation equipment and instruments - electricity and other energy (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Metals - Machines & Equipment (1)

- Sensors (1)

- Shearing machine tools (1)

- Welding, soldering and brazing - equipment and supplies (1)

- Wood veneer - machinery and equipment (1)