- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- press tools

Results for

Press tools - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Precision handling for heavy loads From end-of-line, through rack handling, to automated storage: Lödige has complete control of all the materials handling processes required in the press shop — including tool handling and systems for improved tool maintenance. Your advantages using Lödige solutions in the press shop: Ergonomic tool maintenance Coil handling up to 40 t Safe provision of pressed components Lifting and tilting tables up to 40 t Connection to pressed component storage Linked materials handling systems

Request for a quote

BORNEMANN GMBH

Germany

Manual stamping presses for steel, tool and machine engineering for simply labelling of multi-digit texts. For standard stamping presses we offer font sizes of 1 to 10 mm with 11 labelling fields on the wheel circumference. By removing the pin stop, the wheels can be easily rotated, which allows setting the desired combination. The striking cap can also be replaced.

Request for a quote

SITEMA GMBH & CO KG

Germany

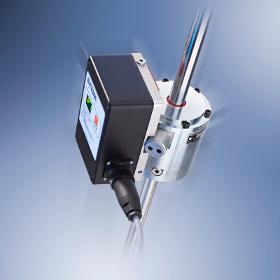

KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electric Locking Unit The electric Locking Unit KFE is used as a stepless locking device on round rods and holds axial forces in both load directions without axial play. It is used where hydraulic or pneumatic solutions are not possible. The holding force is created by the proven spring-operated clamping system as it is used in SITEMA’s hydraulically or pneumatically operated Locking Units. At a drop of the control voltage or in case of failure of the electric supply, the Locking Unit KFE clamps automatically. Therefore, it is also suitable for use in safety relevant applications. To operate the Locking Unit KFE, a supply voltage of 24 V and a control signal for the input command “clamp/release” are sufficient. The Locking Unit is self-monitoring and provides output signals...

Request for a quote

SITEMA GMBH & CO KG

Germany

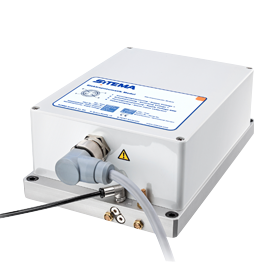

Mechanical Valve Actuator MVA Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electropneumatic module EPM The Electropneumatic Module EPM acts as interface between (electrical) power supply / control and a pneumatic SITEMA clamping head. All pneumatic SITEMA clamping heads with an operating pressure of up to 4 bar and an operating volume of up to 220 cm³ can be pneumatically controlled by the EPM. It is also possible to operate several clamping heads in parallel with one EPM. The EPM is controlled by a 24V supply and switching voltage. The outlet pressure which is required to open or keep open a pneumatic clamping head is controlled by a control signal. If the voltage fails or the input signal is switched off, the pressure is...

Request for a quote

SITEMA GMBH & CO KG

Germany

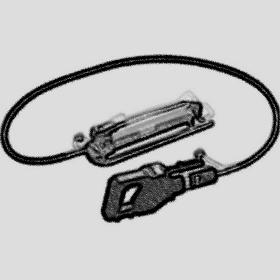

KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Safety Catcher The Mechanical Safety Catcher KRM is operated purely mechanically and requires neither a hydraulic nor a pneumatic system for control. The clamping head is kept open mechanically and acts upon rupture of the suspension (rope, belt, chain, etc.). The energy of the falling mass is then used to generate the clamping force. In applications where lifted loads can be dangerous in case of rupture of the suspension device, Safety Catchers KRM are used to protect people and assure accident prevention. Safety Catchers KRM secure the load at any point of the stroke in a mechanically safe and absolutely reliable way. Due to the principle of self-reinforcing clamping, a very high level of safety is reached. Application example Packing...

Request for a quote

SITEMA GMBH & CO KG

Germany

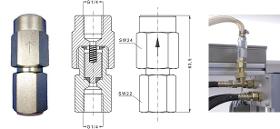

Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Auto Bleeder The SITEMA Auto Bleeder has been specially designed for the use with a SITEMA clamping head. It makes sure that the hydraulic system is constantly bled. Air bubbles in the hydraulic fluid might combust spontaneously under certain conditions (so-called Diesel effect). As a consequence, seals and sealing surfaces can be damaged, causing leakages. Clamping heads are especially susceptible for this phenomenon, as they have only a very small hydraulic volume and are not flushed through at each activation. Air can therefore easily accumulate in the clamping head. This is the reason why the usual initial bleeding at commissioning is often not enough, especially when the line leading to the clamping head points upwards...

Request for a quote

SITEMA GMBH & CO KG

Germany

Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Valve Actuator MVA Secure the rupture of a chain with the full comfort of a pneumatic SITEMA clamping head When a load has to be secured against rupture of a suspension device (e.g. a chain), many customers use our Mechanical Safety Catcher KRM. This unit has the advantage to hold the load immediately upon rupture of the suspension device. Additional sensors to detect rupture of a chain are not necessary. On the other hand, it is not possible to activate the KRM in a user-defined position without rupture of the suspension device, e.g. for maintenance purposes. Here, the Mechanical Valve Actuator MVA comes to your rescue. It is simply put between the suspension device and the...

Request for a quote

KW HYDRAULIK GMBH

Germany

Pressing Pipes Bending Pipes Striping and Peeling of Tube Brochure Tools for Pipeline Construction Drilling of Tubes Cutting and Sawing of Tubes Chamfering Tool for Plastic Tubes

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The Load cell model 8451 has been developed for measuring the forces that occur during press operation. The internal measuring elements have a rugged design, which mean they can cope reliably with the steep force curves that are typical of press applications. They can be fitted or replaced quickly and easily on the press ram without the need for additional components around them. The force sensor is placed between the tool and the press ram and can thus measure the actual compression force directly in the axis of operation. The load cell measures the compression forces between the circular contact surfaces of plunger and tool. The pin on its top side and hole on its lower face are simply provided for mechanical fixing and centering the components correctly. The connecting cables are suitable for drag chains, designed for many movements and stably fastened in the sensor housing.

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

Table presses with different drive types are also suitable for use as a single workstation, as for use in punching systems. The advantage of these presses is that different tools can be used alternately. This is particularly economical in systems with which different articles with different punching patterns are produced.

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

Press-independent tools, for individual use or integrated in systems.

Request for a quote

BIRKAN GMBH

Germany

A quick thickness control of blankets, plates or underlay foils outside the printing press: This is the main function of the transportable, analog BIRKAN thickness gauge. It allows you to check in no time the thickness of your cylinder packing and prevent printing problems. The thickness gauge is equipped with a special feeler for soft materials such as rubber printing blankets. However, other materials not thicker than 5 millimetres can be equally measured.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Lesjöfors manufactures deep drawn parts to customers individual requirement in press machines by either progressive tool or transfer tool solutions as well as opportunities for less automated solutions in case of low volume requirement.

Request for a quote

SPIROL

Germany

Since the development of coil springs in turret tooling, engineers have been challenged to increase the productivity of turret presses even further. In a traditional press, the option of material type and material thickness is limited by the coil springs inability to produce a high force in a short linear distance. When this performance is necessary, coil springs will have a negative effect on the quality of the formed product and efficiency of the manufacturing process. SPIROL® Disc Springs are the solution to form thick materials, large extrusions, and more complex designs. When stacked in series, they are capable of providing a greater, more consistent stripping force than coil springs and require less space. They have become an instrumental component in the advancement of turret punch press tooling. Visit www.SPIROL.com to learn more!

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Assembly immediately upon receipt of order - generally in stock Umbausatz Hydroaggregat Mit diesem Umbausatz kann die Hydraulikpresse S 2.1M Ecoline wie gewohnt mit der Handpumpe oder mit dem ... Category Hydraulic hoses and fittings / Machines and tools / Hose press / Hydraulic unit Product number supplier 43381008

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The multipurpose digital indicator TRANS CAL 7281 can be used wherever there is a need to perform high-precision, in-situ calibrations of sensing components used in equipment such as presses, torque tools or pressure-regulating systems. An optional factory calibration certificate or German-accredited DKD/DAkkS calibration certificate can be provided when the measurement device needs to be used as a reference. This provides a quick and cost-effective way of assessing a system with traceable documentation of measurement results. If a reference measurement cannot be made because the sensor location is difficult to access, it is still possible to test the zero point, the input, output and isolation resistance as well as the calibrating offset of the fitted sensor. It is also possible to check the indicating device by measuring the excitation voltage and simulating the characteristic values (mV/V or V) of the sensor used.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This hydraulic crimper with patented C-form pressing tool facilitates the radial infeeding of complex hose assemblies. It is particularly well suited for hoses used in automotive manufacturing. * According to the fitting

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIMO GROUP GMBH

Germany

Economic and high performance punching machine for high volume production FRIMO's EcoCut punching machine is ideally suited for trimming very complex and large plastic components such as instrument panels, door panels and armrests. Its high capacity makes it the optimal choice for large-scale production. The EcoCut has been specifically developed for trimming towards the ram and in many additional punching directions. The product fixture is integrated directly into the lower table. The vertically driven upper tool replaces the press ram.

Request for a quote

HUBTEX MASCHINENBAU GMBH & CO. KG

Germany

Safe and as fast as possible – those are the crucial prerequisites that modern tool changers need to satisfy. HUBTEX tool changers with load capacities of up to 65 tonnes help to reduce the changing times for pressing and stamping tools and so improve production efficiency. The compact running gear also allows for extremely low entrance heights underneath machinery. Load capacities up to 65,0 t Tool platform with lift hights up to 3000 mm

Request for a quote

ECKOLD GMBH & CO. KG

Germany

This cordless clinching device is a low-cost and universal frame from the ECKOLD range of hand-held machines. Apart from the standard models, we offer of course also customised frames. Do you want to produce a prototype? Do you need a fall-back option for your production? Or are there clinching tasks to be performed on site? Then opt for the MCD 30/50 AH portable clinching frame. • Universal application • Portable and cordless • Sturdy design, suitable for construction side • Large opening width, good component accessibility • Frame head 360° turnable • Continuously adjustable path limit • Different clinching techniques possible • Comfortably packed in transportation case • LED light • Digital display • Klauke i-press software Clinching tools (punch and die) are not included in the scope of delivery. They must be chosen separately, based on the actual joining task. Contact us for a customised offer, tools included!

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

VIBGUARD IIoT offers a choice of 12, 16 or 20 measuring channels which are sampled in parallel and synchronously. This allows even the most complex equipment to be continuously monitored and protected against unplanned shutdowns. VIBGUARD IIoT works autonomously and performs the measurement tasks automatically. The measurement data such as time signal, characteristic value, FFT spectrum, kinetic wave path (orbits), or torque are processed in parallel and almost in real time and can be correlated with the running production process. The fast data processing makes VIBGUARD IIoT the perfect monitoring and diagnostic system for systems with short operating cycles, such as cranes, machine tools, presses, or for machines with highly dynamic processes, such as test benches, wind turbines or chain conveyors. All critical fans and pumps can also be monitored easily but effectively with VIBGUARD IIoT.

Request for a quote

1A STAR TECHNISCHE KUNSTSTOFFE GMBH

Germany

STAR high quality bending film / folding foil is a high quality product, which offers best protection for parts and press brake tools on nearly every press brake machine. It is tested and developed under most difficult conditions. Test our high quality bending film / folding foil / antiscratch film and see, how you can protect your press brake tools, your bended parts and save money by saving time and avoiding extra work! Avoid following problems : Scratches imprints marks other problems caused by the direct contact from press brake tool and part extra work to clean the part after having scratches, imprints or marks scratches on press brake tools

Request for a quote

ULBRICH GMBH

Germany

Picture 1 Prvoted bogy test stand Picture 2 Press tool to press the bearing cup into the bogie Picture 3 Spring tester with supply line on both sides Picture 4 Test press to test the fitting of the whell disc Picture 5 Test stand for design material developement on bogies wit 16 hydraulic axis

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

For more than 25 years our name has stood for experience, professional competence and consumer-orientated service. Moreover, our clients hold the opinion that our skills in producing multi-part press tools and fixture constructions are absolutely convincing. These tools are implied for instance within the framework of electronic and automotive industry in favour of processing different materials. Thus, your needs will be developed gradually. By using up-to-date software we produce high standard multi-part press tools for national and international clients. With the professional help of the CAD/CAM-Software (Cimatron) we generate 3D-construcions and solids. For data migration we offer several interfaces: Step – DWG – IGES – DXF – just choose what you need. Immediate interfaces that lead directly from the CAD-workstation to the machine ensure shortest processing times.

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

Due to our 25 years of experience we are able to produce high-class qualities on favourable terms in the field of tool manufacturing as well. You are looking for the optimal tool, that matches your needs and that keeps your costs low even in the long term? No matter whether we are assigned by automotive, electric or any other sector of industry: we are your tool partners! Let us counsel you individually and you will profit with our nice price-performance ratio soon. Besides multi-part press tools and by using modern CAD-techniques cutting tools we produce deep drawn tools, bending tools and fixture constructions for stamping, bending and drawing parts with a press capacity up to 2800 kN and a sheet thickness of 4.0 mm. Screw threads can be formed non-cuttingly up to M12 during the stamping process. Our tool maker craft tools routinely and professionally that bare a high complexity. Because we can use our experience of long duration in manufacturing precise tools, ...

Request for a quoteResults for

Press tools - Import exportNumber of results

26 ProductsCountries

Category

- Presses, hydraulic (3)

- Calibration equipment (1)

- Import-export - steels and metals (1)

- Monitoring and control equipment (1)

- Press relations (1)

- Punching machine tools (1)

- Punching machines, plastic (1)

- Screw cutting - steels and metals (1)

- Sensors (1)

- Standard gauges (1)

- Welding work - steels and metal (1)